Self-reliance type plunger system

A self-operated, plunger technology, used in variable capacity pump components, production fluids, liquid fuel engines, etc., can solve problems such as increased labor intensity and operating time, wellhead sand production, and increased pressure difference fluctuations in the well. Reduce labor intensity and working time, reduce excitement, and prevent the effect of moving too fast or too slow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

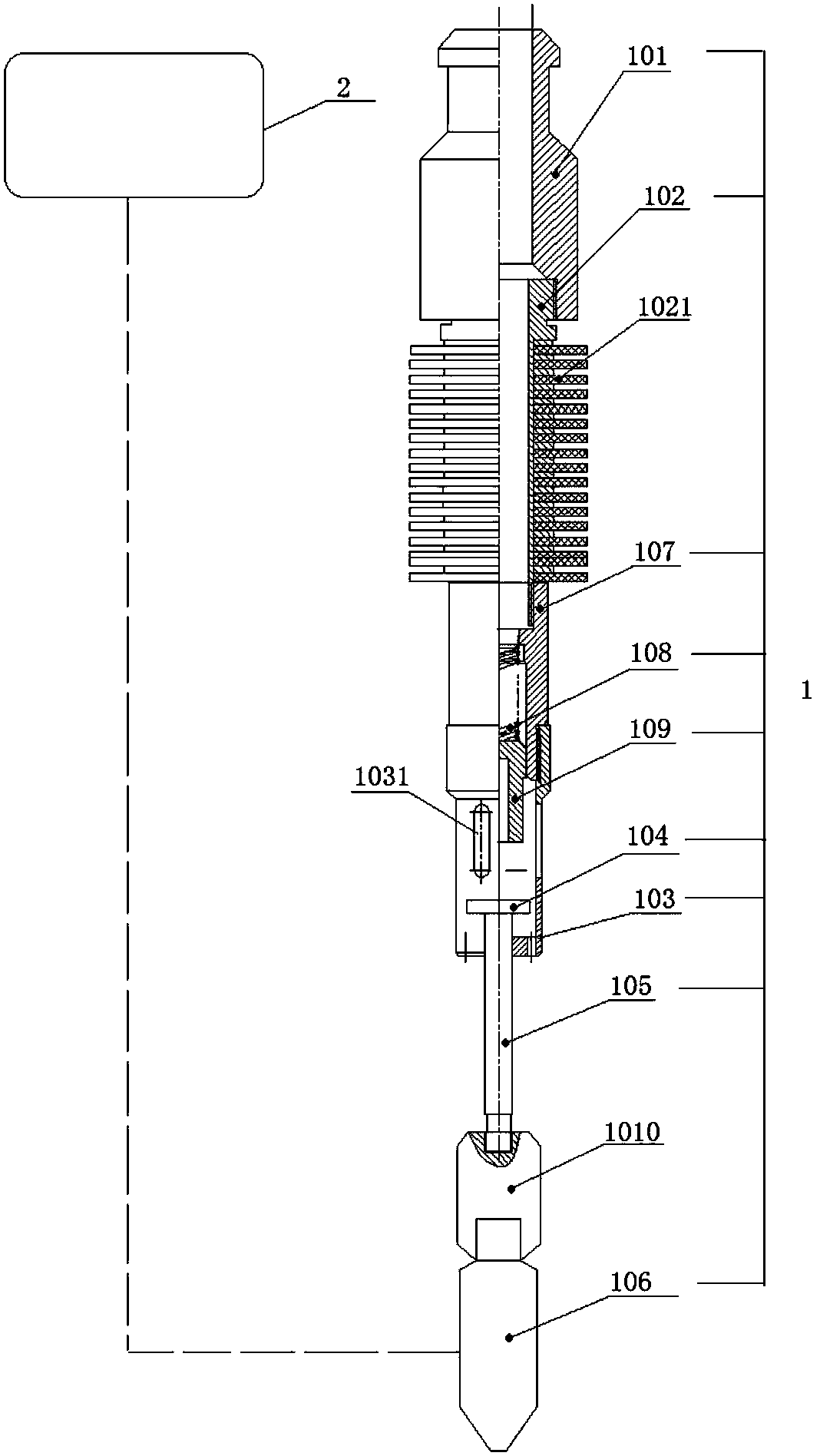

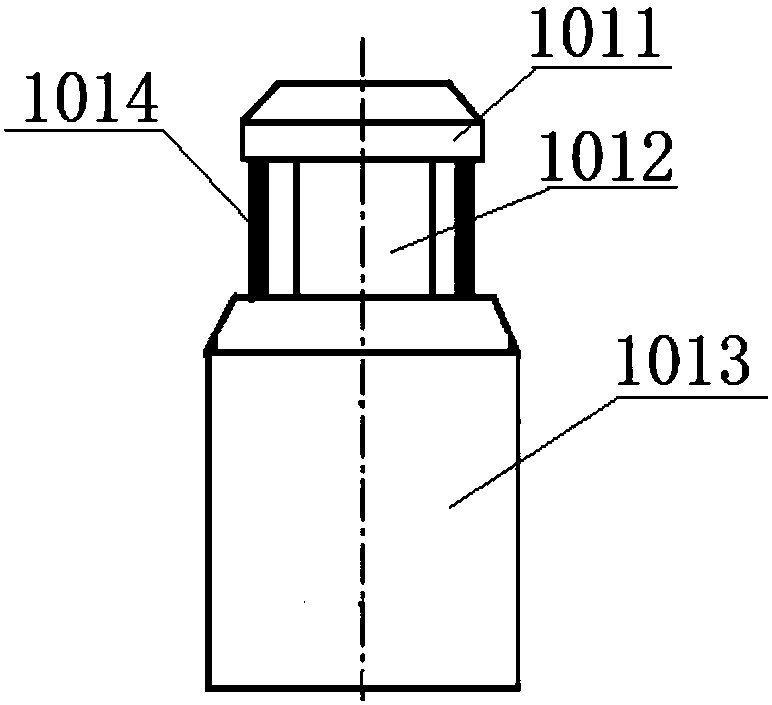

[0056] Embodiments of the present invention provide a self-operated plunger system, such as figure 1 As shown, the plunger system includes: a plunger 1 and a monitoring system 2; further, the plunger 1 includes: a fishing head 101; a cylinder 102 connected to the lower end of the fishing head 101 and capable of sliding dynamically and sealingly along the inner wall of the tubing; A base 103 that is connected to the lower end of the cylinder 102 and has a plurality of through holes 1031 on the side wall; The lower end faces are sealed against each other; the upper end extends into the base 103 and is connected to the lower end of the valve core 104;

[0057] It should be noted that an oil and gas well includes: a casing, an oil pipe lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com