Continuous collinear spray-coating winding prefabricated directly-buried thermal insulation pipe production line and applications thereof

A technology of prefabricated direct-buried and thermal insulation pipes, applied in applications, other household appliances, household appliances, etc., can solve the problems of many labors, long spraying time, and reduce the production efficiency of production lines, so as to shorten the process flow, simplify the production process, save money The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

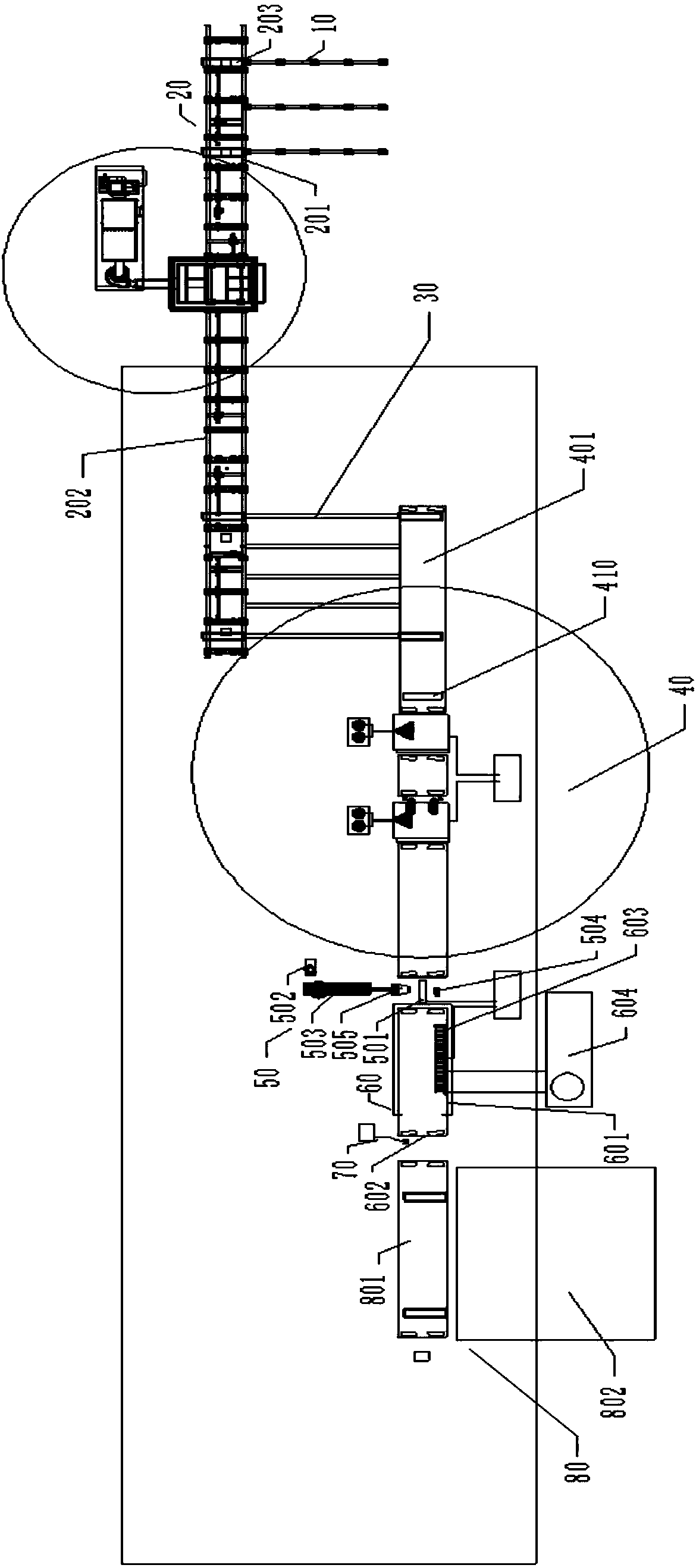

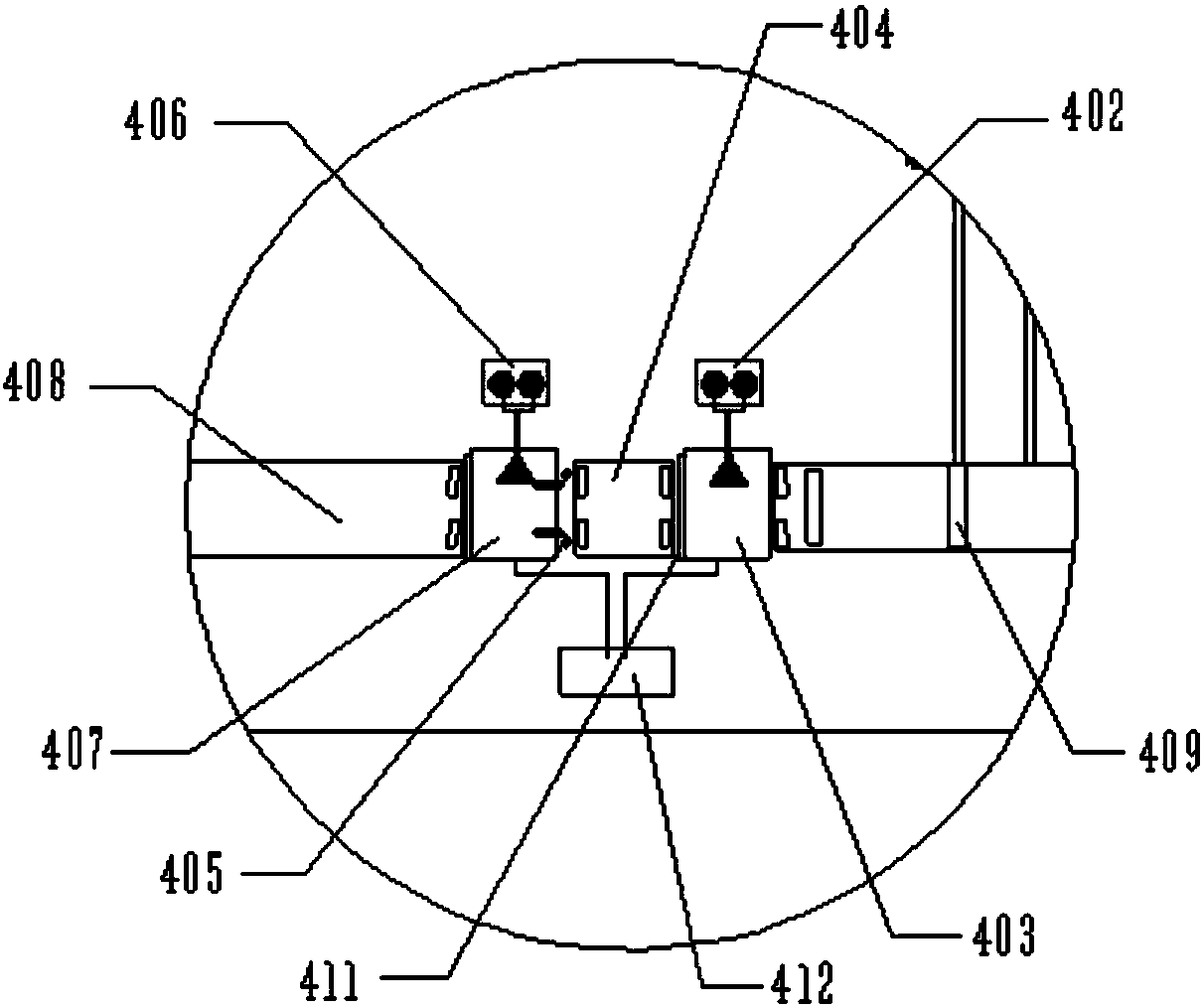

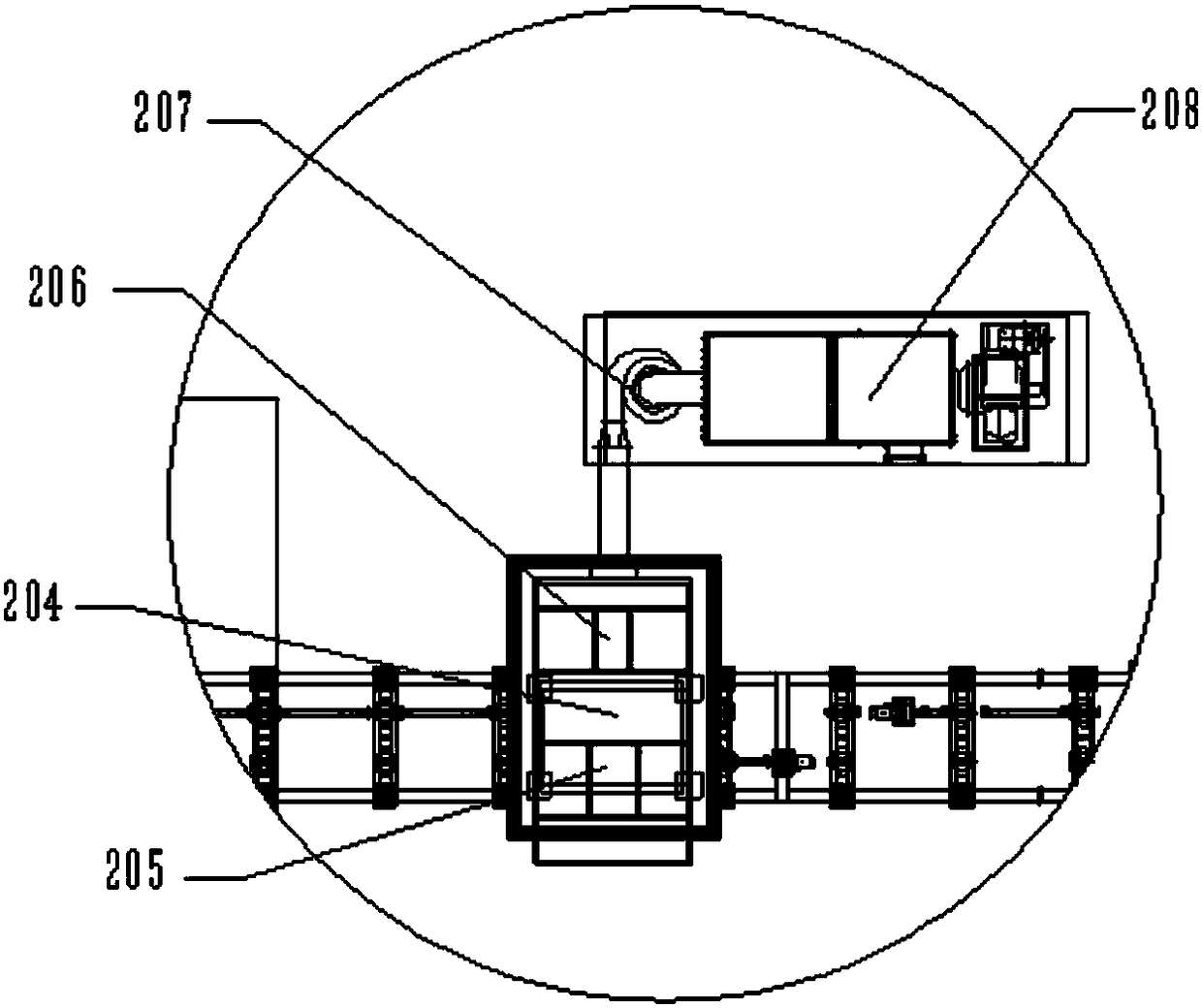

[0032] Such as Figure 1-Figure 4 As shown, a continuous collinear spraying winding prefabricated direct-buried insulation pipe production line, including upper pipe platform one 10, rust removal and shot blasting part 20, upper pipe platform two 30, polyurethane spraying part 40, polyethylene winding part 50, spraying The cooling part 60, the cutting part 70 and the finished product storage part 80, the output end of the upper tube platform one 10 is connected to the input end of the derusting and shot blasting part 20, and the output end of the derusting and shot blasting part 20 is connected to the input of the upper tube platform two 30 end, the output end of the upper pipe platform 2 30 is connected to the input end of the polyurethane spraying part 40, the polyurethane spraying part 40, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com