Inner flat curved copper strip embedded tooling of motor sealing ring and embedding method

A seal ring and arc-shaped technology, which is applied in the field of manufacturing tooling for motor seal rings, can solve problems such as low positioning accuracy and poor assembly stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

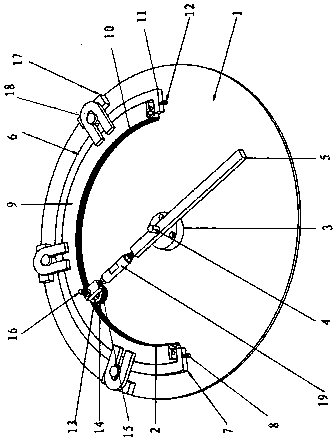

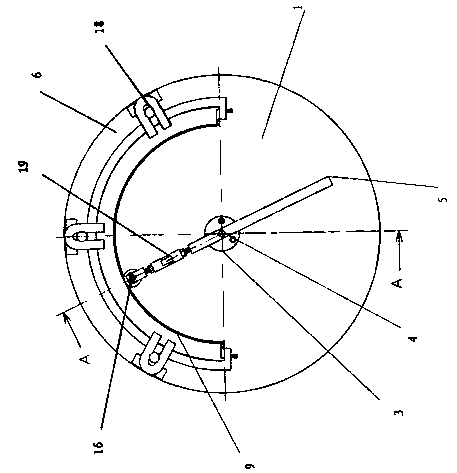

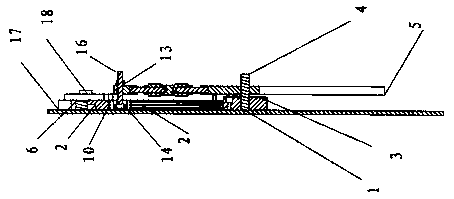

[0017] The present invention will be described in detail below in conjunction with the drawings:

[0018] A tool for inserting flat arc copper strips on the inner side of a motor sealing ring, comprising a circular bottom plate 1, an arc flat copper strip 2 and a steel mother half ring 9. A steel with a U-shaped opening is provided on the inner surface of the steel mother half ring 9 The annular groove 10 of the mother body is fixedly provided with a central support platform 3 at the center of the top surface of the circular bottom plate 1, and an arc-shaped positioning strip 6 is provided on the inner side of the outer circle of the top surface of the circular bottom plate 1, and inside the arc-shaped positioning strip 6 A steel mother half ring 9 is attached to the arc surface, a center pin 4 is provided on the center support 3, a swing rod 5 is hinged on the center pin 4, and a bearing 13 is provided at one end of the swing rod 8. The bearing 13 is provided with a rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com