Tube feeding device

A feeding device and feeding technology, applied in the field of pipe feeding devices, can solve problems such as excessive speed, no reciprocation of feeding, processing waste and increased production costs, etc., and achieve the effects of reasonable structural design, guaranteed use effect, and good coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

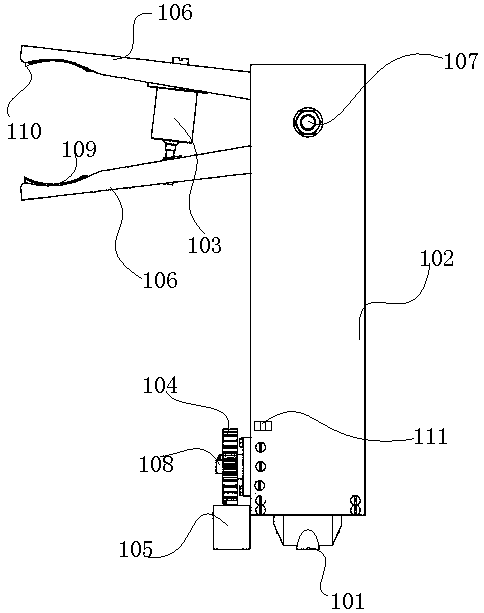

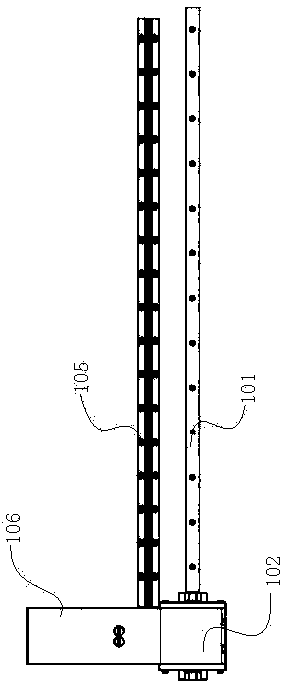

[0020] Such as Figure 1-2 As shown, a pipe material feeding device, the feeding device includes a feeding guide rail 101, a feeding support 102 arranged on the feeding guide rail 101, a clamping claw arranged on the feeding support 102, and a short stroke between the clamping claws Hydraulic cylinder 103, the sliding gear 104 that is located on the feed support 102, the rack 105 that is compatible with the slide gear 104 and the motor that is compatible with the slide gear 104; The feed guide rail 101 is an arc feed guide rail; The feed support 102 is provided with the give way groove that is adapted with arc-shaped feeding guide rail 101; Clamping claw comprises symmetrically set clamping minions 106, and clamping claw is hinged on the feed bearing 102 by positioning pin 107, and sliding gear 104 is on rack 105 Do reciprocating motion on the top, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com