Novel butt joint structure of conductive slide ring

A conductive slip ring, a new type of technology, is applied in the direction of connection, circuit, electrical components, etc. It can solve the problems of mis-insertion of male pins and female pins, inaccurate positioning of the rotating butt joint, and burning of the pin holder, so as to facilitate disassembly and installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

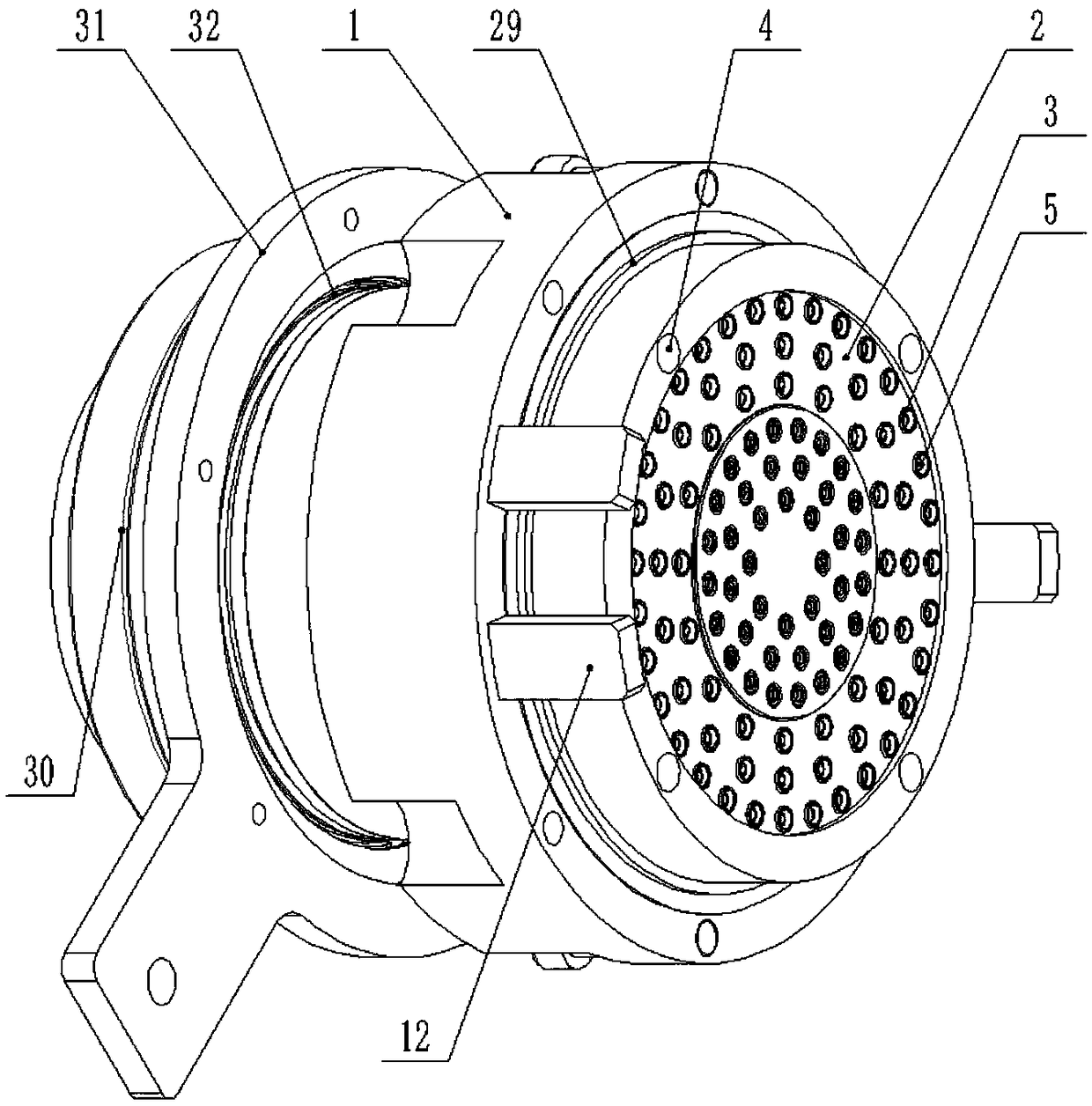

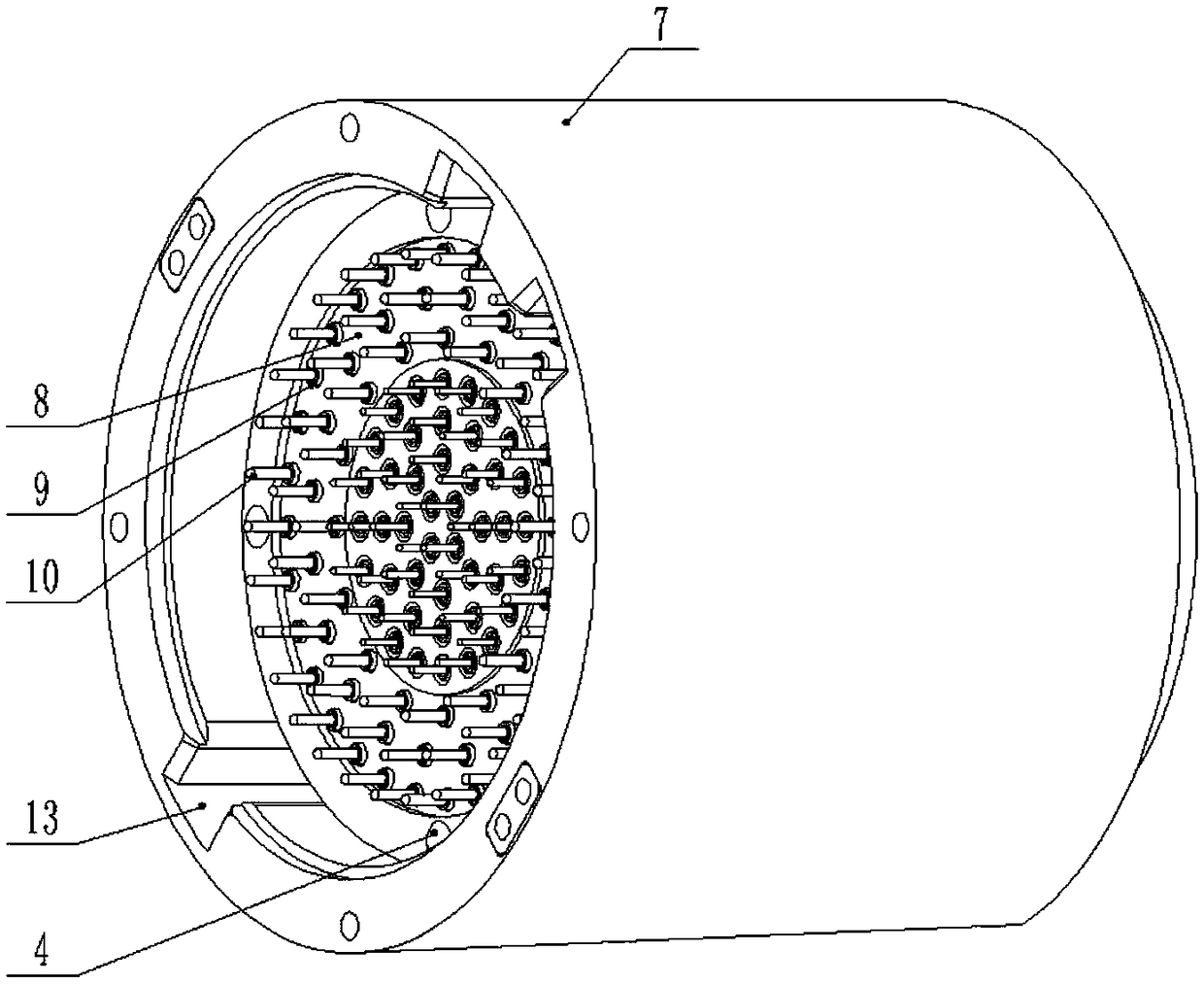

[0037] Such as Figure 1-10 As shown, a new docking structure of a conductive slip ring includes a female pin socket assembly and a male pin plug assembly connected to the female pin socket assembly; the female pin socket assembly includes a female pin bearing mounting seat 1, a female pin mounting seat assembly 2. The female needle sleeve 3, the shaft step screw 4 and the female needle assembly 5, the female needle bearing mounting seat 1 is provided with a support bearing 30 at the end far away from the female needle mounting seat assembly 2 and a support bearing 30 is provided. The bearing baffle 31 is provided with a rotor flange sealing gasket 32 between the bearing baffle 31 and the female needle bearing mounting seat 1 . The support bearing 30 adopts NSK precision bearings, and both ends are contact seals. Ensure the stability and tightness of the product in use.

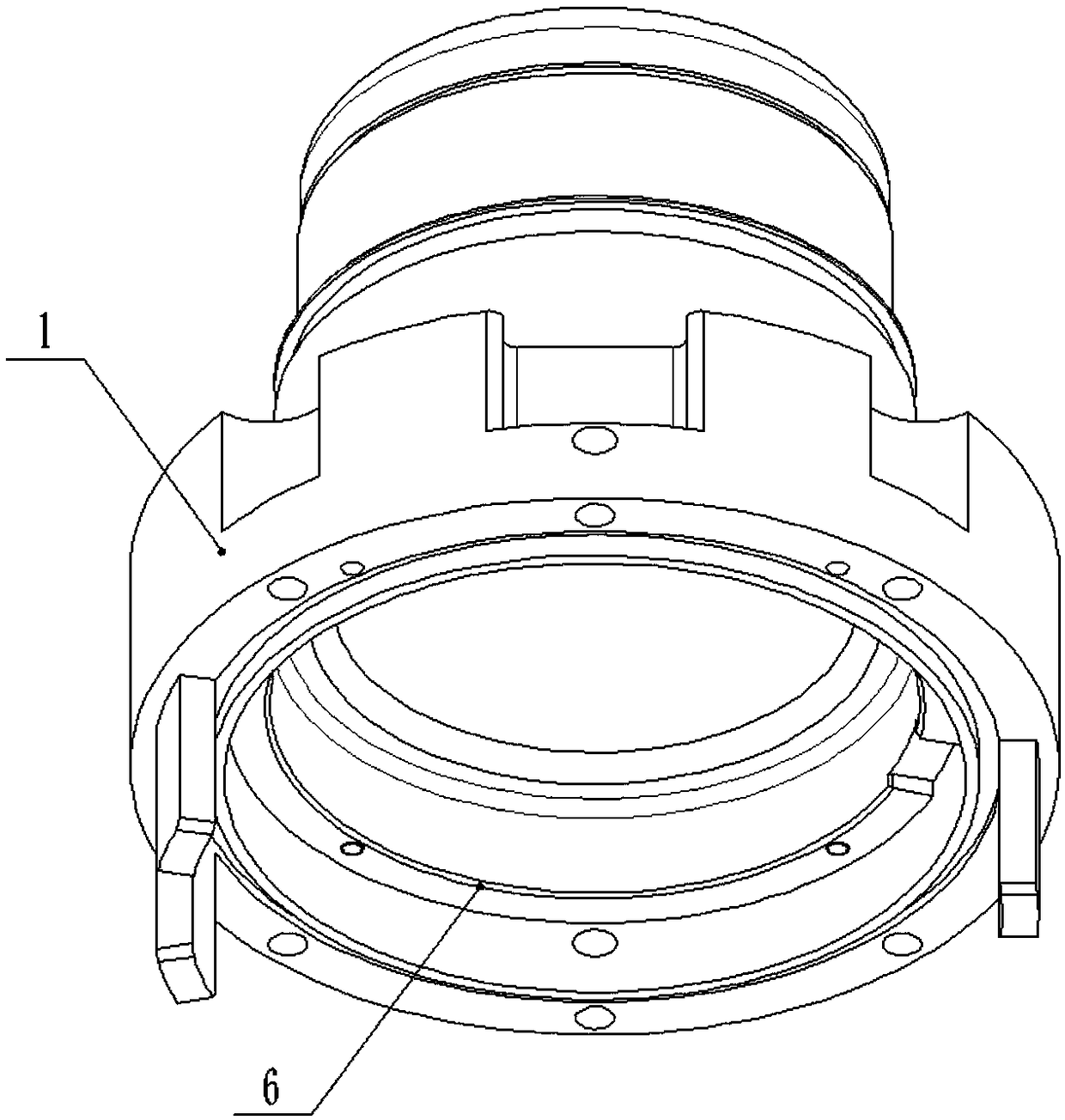

[0038] Such as image 3 As shown, the female needle bearing mounting seat 1 has a first boss 6 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com