A light-weight external wall panel connection node

A technology for hanging wall panels and connecting nodes, which is applied to walls, buildings, building components, etc. It can solve the problems of wall panel damage, many customized parts, and high installation accuracy requirements, so as to avoid local crushing, relieve stress concentration, and improve adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

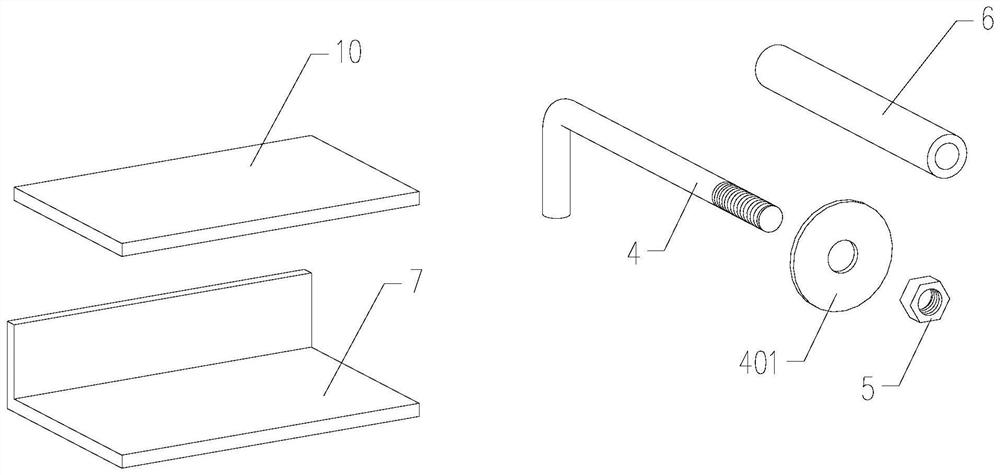

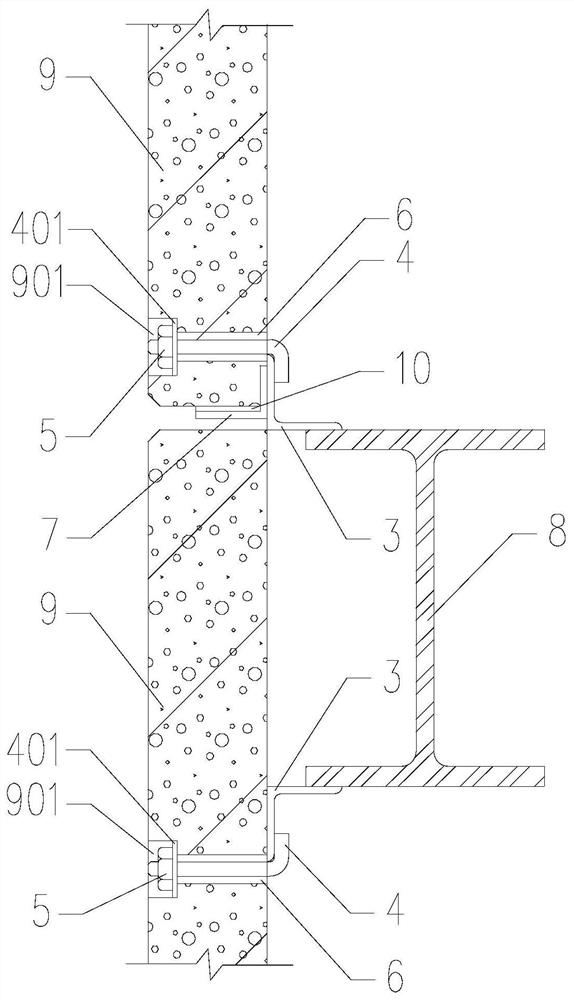

[0032] refer to figure 1 , figure 2 , image 3 , this embodiment discloses a light-weight external wall panel connection node, including an upper node assembly 1 and a lower node assembly 2, the upper node assembly 1 and the lower node assembly 2 are respectively located on the upper side and the lower side of the same wall panel 9, figure 2 , image 3 The upper side and the lower side of two different wall panels 9 are shown in Fig. 2 also includes a supporting plate 7, and the connectors 3 of the upper node assembly 1 and the lower node assembly 2 are all fixed to the main structural member 8 of the building.

[0033] In this embodiment, the main structural member 8 of the building is one or more of steel beams, concrete beams, composite beams, concrete floors, and composite floors. Or when combining floor slabs, there are embedded parts for installation in concrete beams, concrete floors, composite beams and composite floors.

[0034] The L-shaped bolt 4 is fixed on ...

Embodiment 2

[0048] This embodiment discloses a construction method for a connection node of a lightweight external wall panel, which is used to form the connection node of a lightweight external wall panel in Example 1, including the following steps:

[0049] Step A: Process the wallboard, assemble the upper node assembly and the lower node assembly, assemble the upper node assembly and the lower node assembly respectively, and process mounting holes on the upper and lower sides of the wallboard;

[0050] Step B: Install the upper node assembly and the lower node assembly, install the connectors of the upper node assembly, the connectors of the lower node assembly and the supporting plate on the corresponding parts of the main structural members of the building, and place the elastic backing plate on the fixed supporting plate superior;

[0051] Step C: Install the wall panel, hoist the wall panel with installation holes obtained in step A to the predetermined position, place the wall pan...

Embodiment 3

[0054] This embodiment discloses another construction method for connection nodes of lightweight external wallboards, based on Embodiment 2, and differs from Embodiment 2 in that:

[0055] Step A includes the step A1 of determining the parameters of the node components, the step A2 of assembling the node components, and the step A3 of opening installation holes on the wallboard;

[0056] Step A1: Determine the material and geometric parameters of the connecting piece, L-shaped bolt, elastic sleeve, supporting plate and elastic backing plate according to the design requirements;

[0057] Step A2: Insert the L-shaped bolt into the elastic sleeve to form an assembly;

[0058] Step A3: After positioning the opening position of the wallboard according to the design requirements, drill the installation hole at this position. The inner diameter of the installation hole is slightly larger than the outer diameter of the elastic sleeve, and the diameter of the installation hole is withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com