Magnetic sheet type transformer with low mounting height

A technology of installation height and transformer, applied in the field of transformers, can solve the problems affecting the current passing ability and reliability of the winding, the power density of the planar transformer cannot be maximized, and the resistance value of the electrical connection point is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described in conjunction with the following examples.

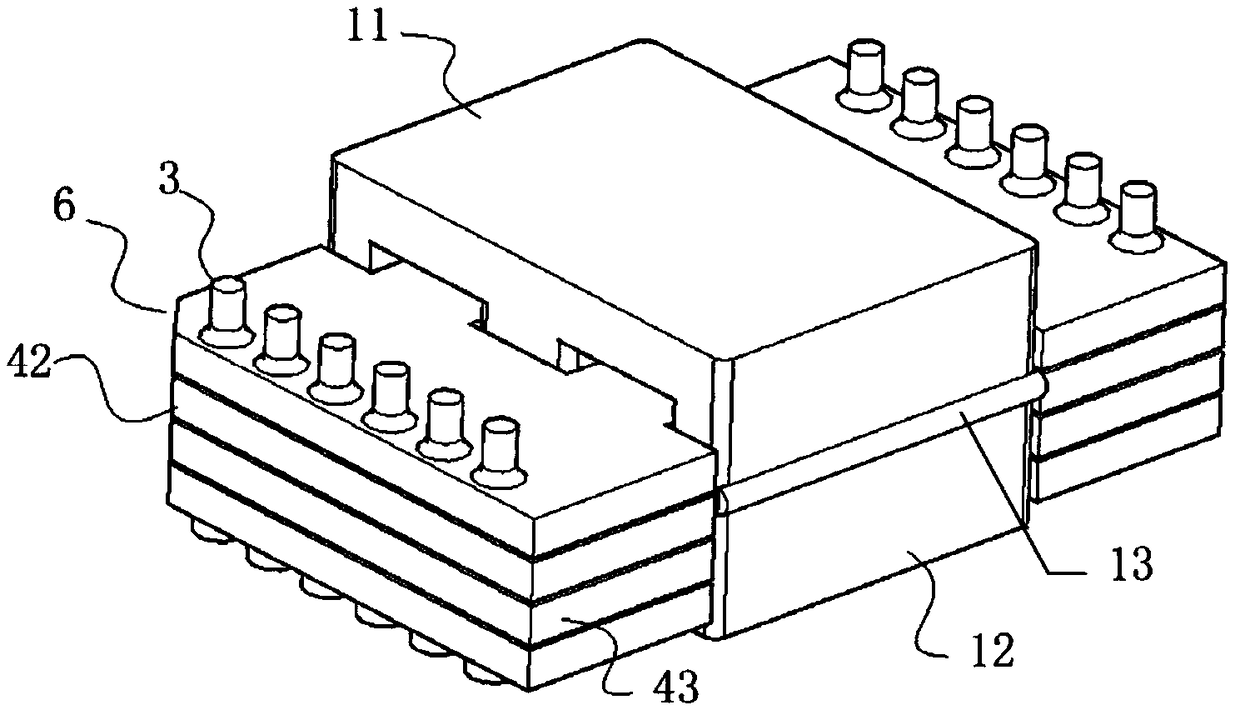

[0025] Depend on Figure 1 to Figure 6 It can be seen that a low installation height magnetic chip transformer described in this embodiment includes upper and lower symmetrical upper E-shaped magnetic cores 11 and lower E-shaped magnetic cores 12; the upper E-shaped magnetic core 11 and the lower E-shaped magnetic core There are multi-layer PCB copper clad laminates between the cores 12;

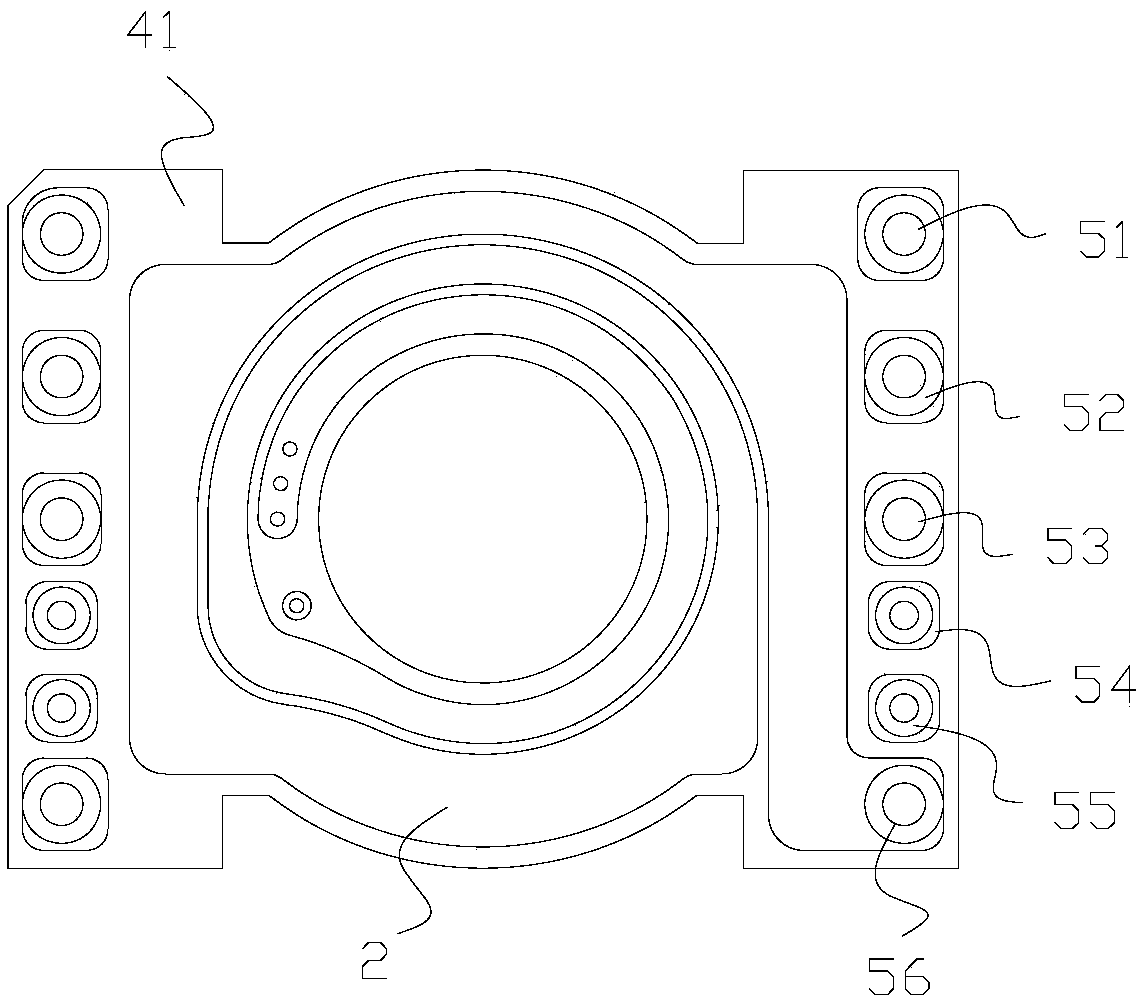

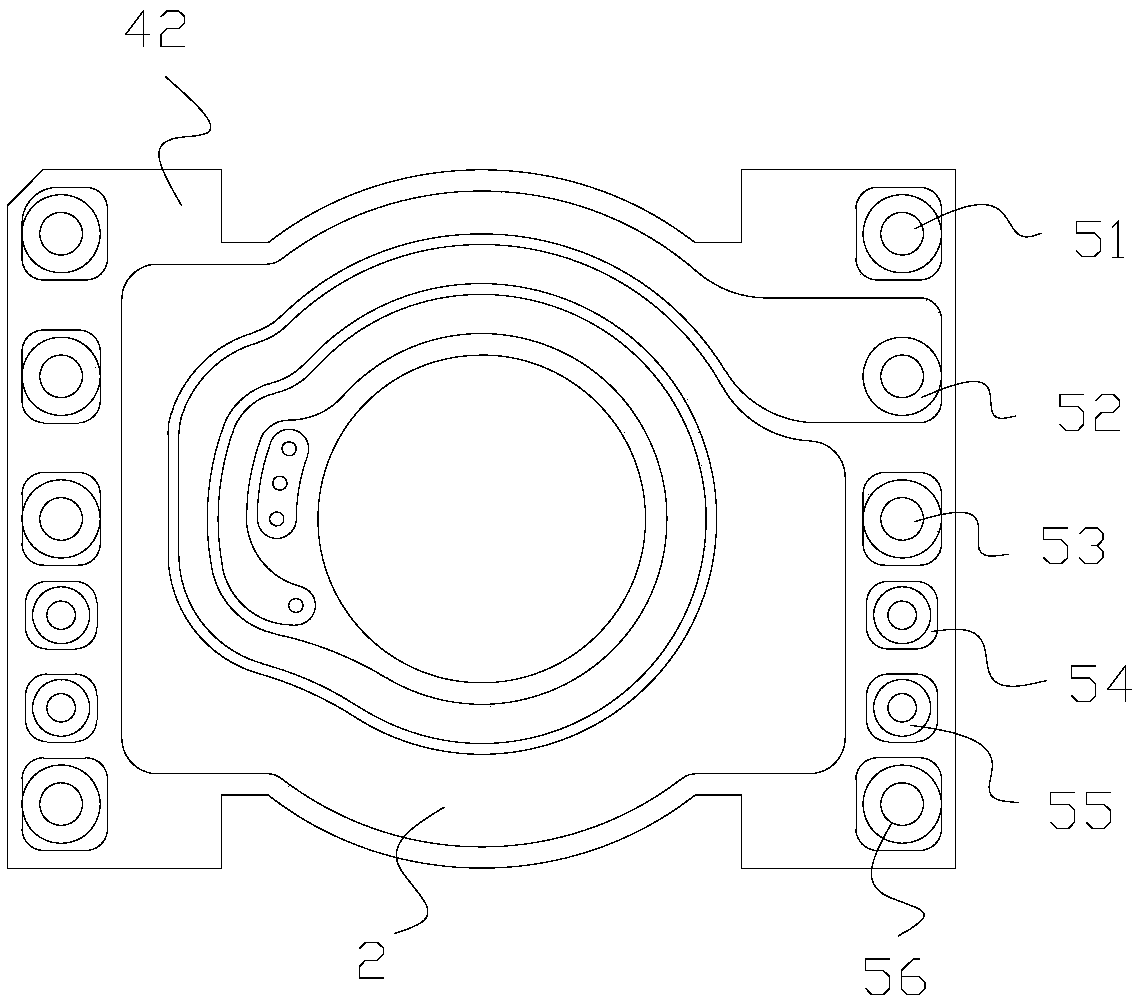

[0026] Each of the PCB copper clad boards includes a PCB board and a winding 2 etched on the PCB board; each PCB board and each winding 2 are provided with through holes;

[0027] The low installation height magnetic chip transformer includes a conductive column 3 for conducting conduction between each PCB board and each winding 2; .

[0028] Specifically, the low-installation-height magnetic chip transformer described in this embodiment adopts a plane in which 2 turns of corresponding windings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com