Cold water machine installing bracket capable of preventing liquid leakage

A technology for installing brackets and water chillers, which is applied in the direction of machines/brackets, projection devices, supporting machines, etc. It can solve the problems of water leakage, electrical conductivity, and service efficiency reduction of chillers, and achieve the effect of simple realization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

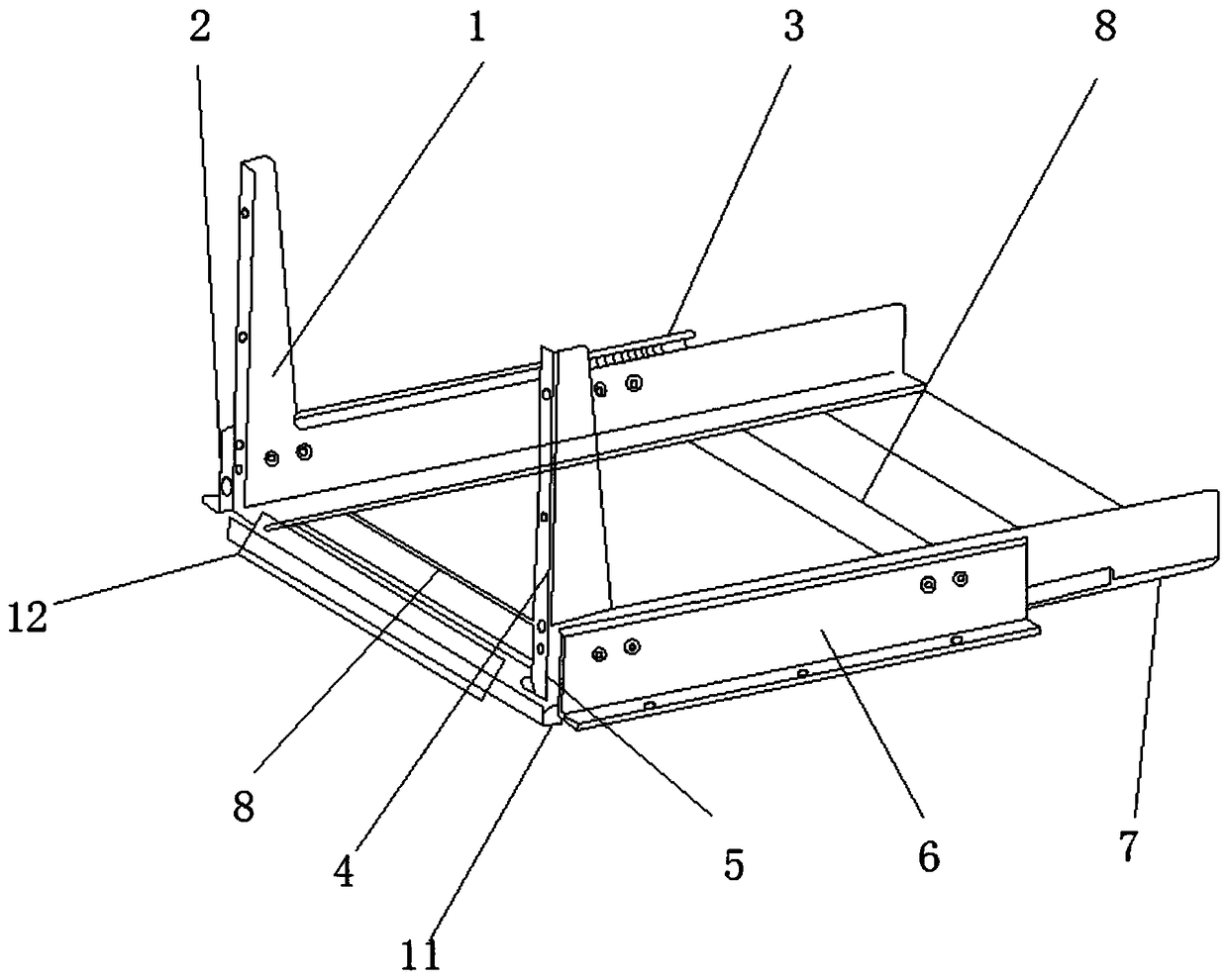

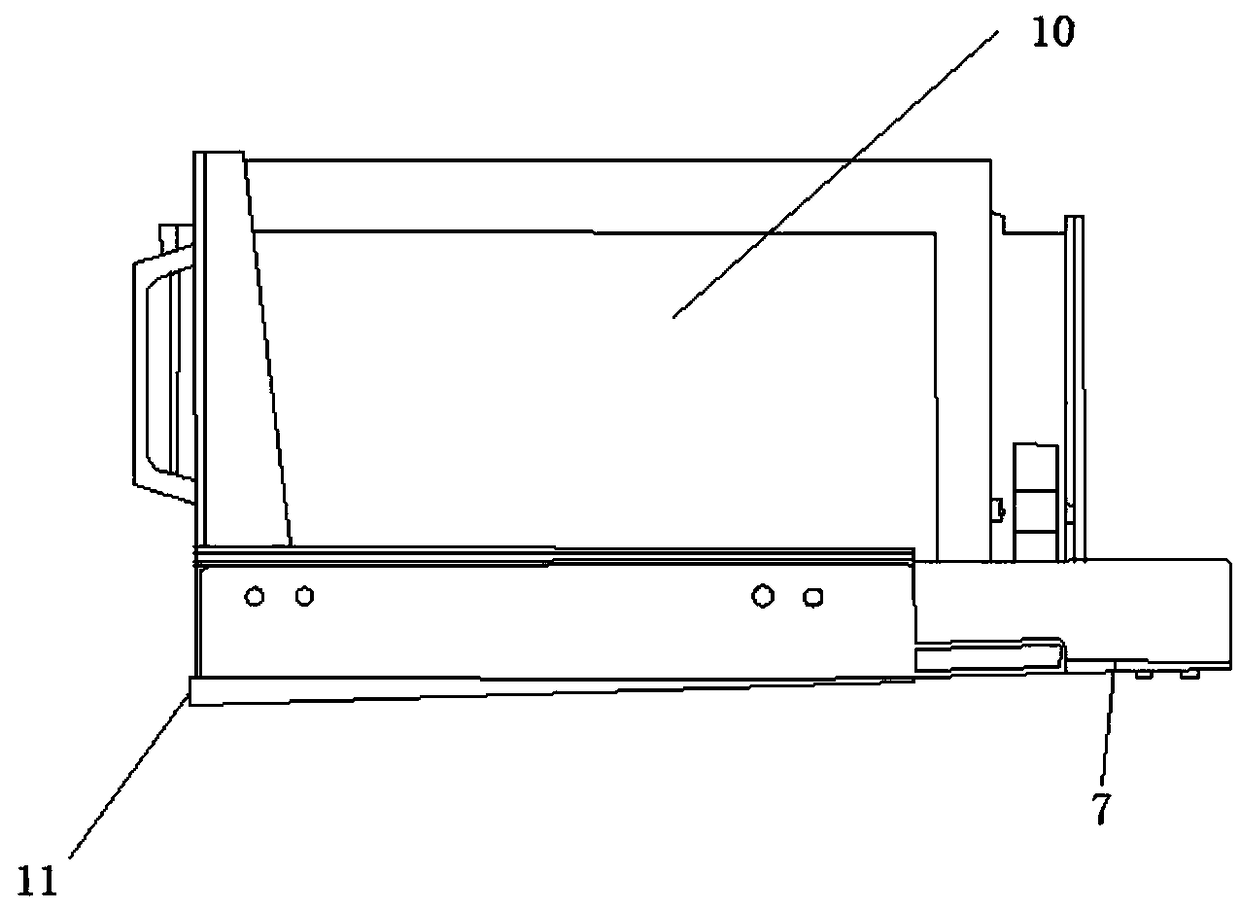

[0033] see image 3 , the anti-leakage tray 7 of the chiller installation bracket is designed to have an inclination angle of 3°. When liquid leakage occurs inside the chiller, the liquid will drop through a rectangular groove between the two reinforcing ribs 8 due to gravity. In the water storage tray 11, it flows to a low place and converges to the front portion of the water storage tray 11. Because the water storage tray 11 has a certain depth, it can hold a certain amount of liquid, so the liquid will not leak below. At the same time, it cooperates with the color-changing label 9 attached to the front of the water storage tray 11. When it encounters water, the color-changing label 9 will turn red and spread outward. observed, the user can then notify a professional to carry out an overhaul.

Embodiment 2

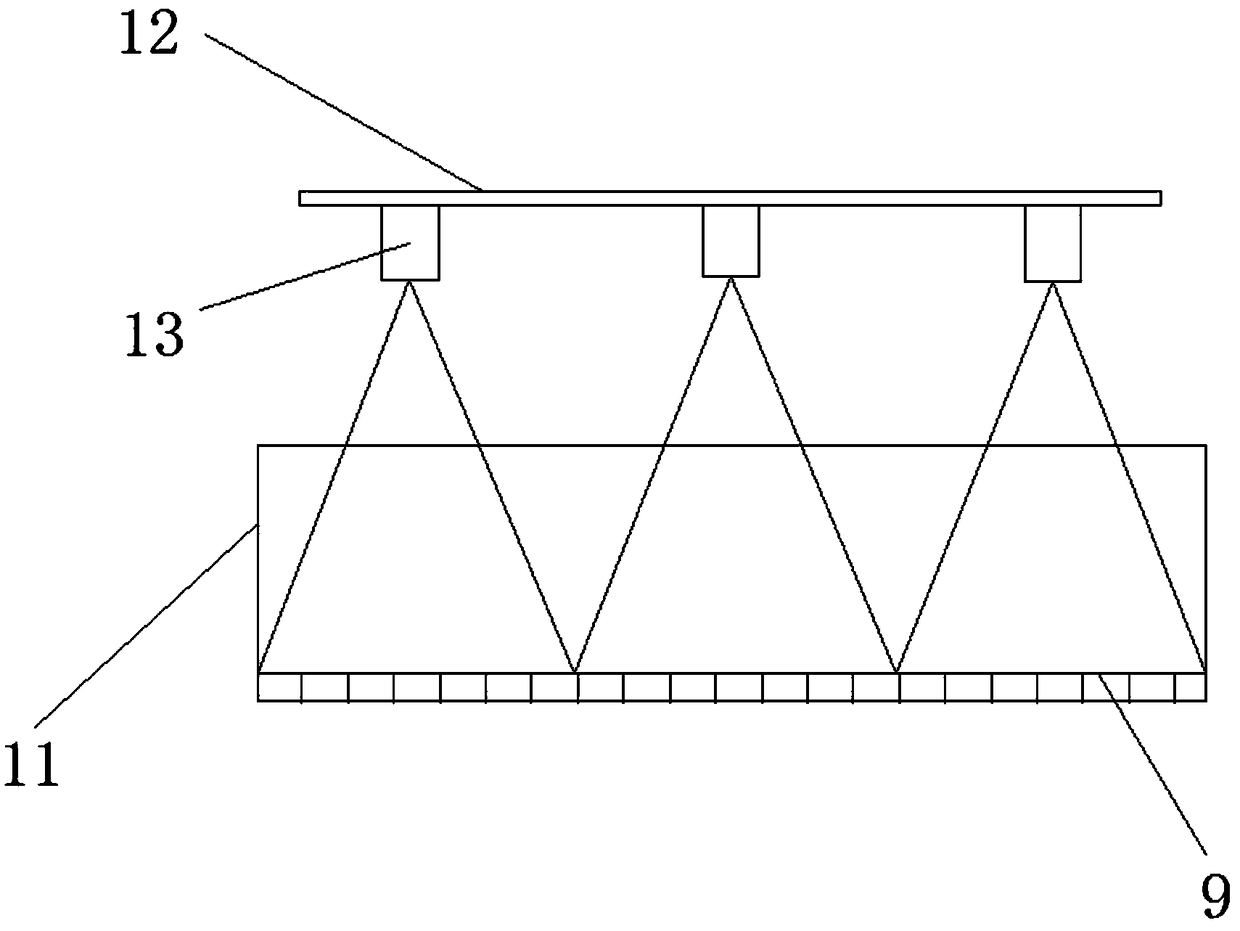

[0035] see Figure 4 , through the color recognition sensor 13 on the upper part of the color-changing label 9 of the water storage tray 11, the three color recognition sensors 13 are electrically connected, and the color recognition sensor 13 is electrically connected to the controller outside the bracket through the communication line, when When the discoloration label 9 does not meet the cooling liquid, it is white, and the output of the color recognition sensor is 0, and the alarm is not triggered. When the color-changing label 9 encounters the coolant, the label will turn red, and the color recognition sensor 13 outputs 1 through the display screen, and a magnifying glass is provided on the inner side of the upper end of the front cover 12 at the display screen, and the magnifying glass is similar to a magnifying glass structure. The displayed 0 or 1 can be enlarged to see more clearly. The material of the front cover 12 is a transparent acrylic plate, which is convenient...

Embodiment 3

[0037]The positions of the color-changing labels 9 can be attached at different heights, and the corresponding color recognition sensors 13 are also installed at different positions. When the coolant reaches different heights, the labels at different positions will change color, and the corresponding color recognition sensor 13 can detect the color change of the corresponding label, thereby triggering alarms of different levels, and performing related processing according to different levels. Depending on the height of the color-changing labels 9, the lowest height is the first-level color-changing label 91, followed by the second-level color-changing label 92 and the highest third-level color-changing label 93. The first-level color-changing label 91 triggers a first-level alarm, and only a warning message is sent. to the display screen; the secondary color-changing label 92 is triggered to trigger a secondary alarm, whether the temperature of the joint engine has risen, if th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com