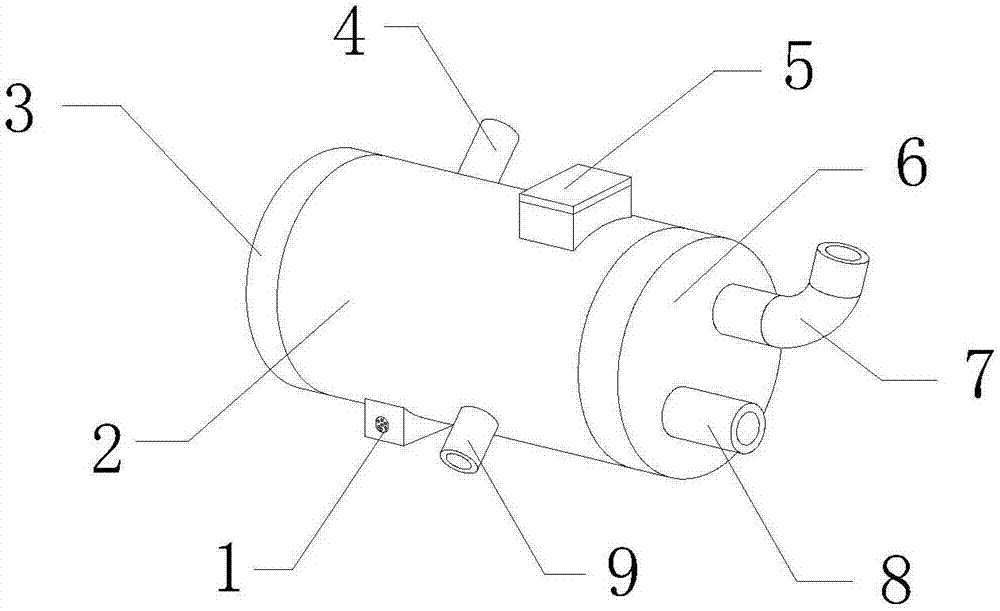

Combined type heat exchange equipment for novel marine diesel engine

A technology for marine diesel engines and heat exchange equipment, which is applied in mechanical equipment, engine cooling, engine components, etc., can solve problems such as failure to detect pipeline water leakage in time, increase equipment maintenance time, and inability to quickly remove moisture, and achieve high reliability. , moisture to dry quickly, to avoid the effect of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

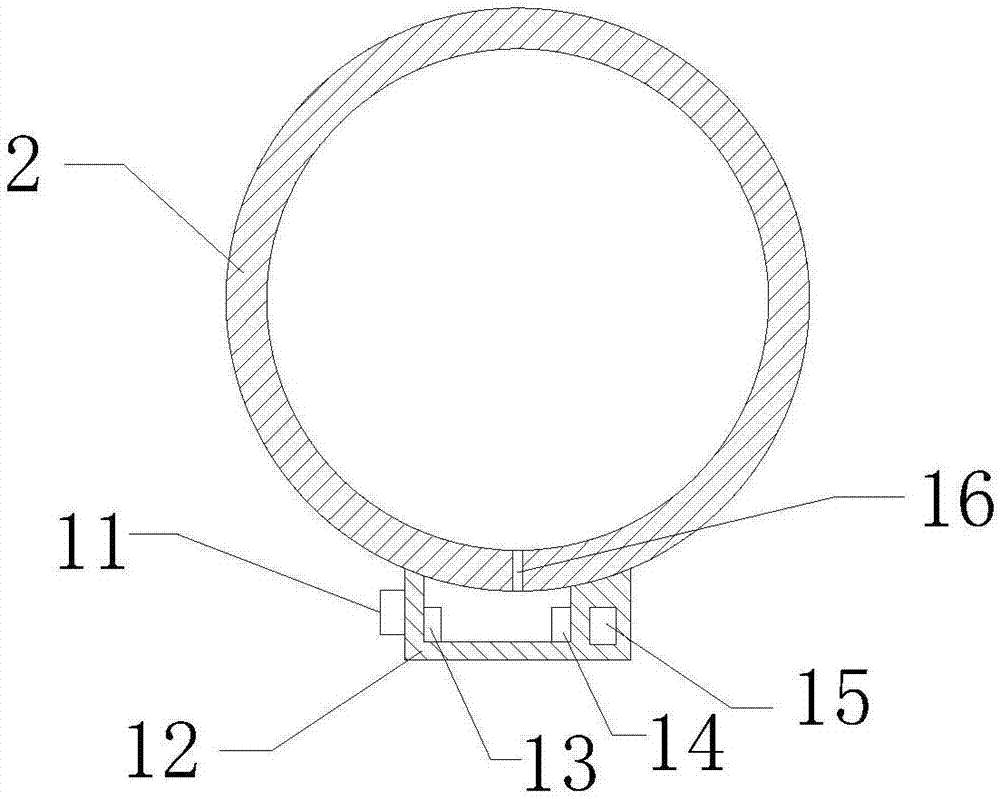

[0024] Specific implementation method: when there is a water leakage in the cylinder body 2, the leaked water flows into the liquid collection box 12 through the leakage port 16, so that the contact piece 13 and the contact piece 2 14 are in the water, because the water has conductivity, thus contacting Connect the circuit between the storage battery 15 and the alarm bell 11, and the alarm bell 11 will send out an alarm sound when it is energized. After the user hears the alarm sound, he should repair the present invention in time, so as to solve the original heat exchanger's non-leakage alarm function. Cause people to be unable to discover pipeline leaking situation in time, very easily cause the problem of accident enlargement.

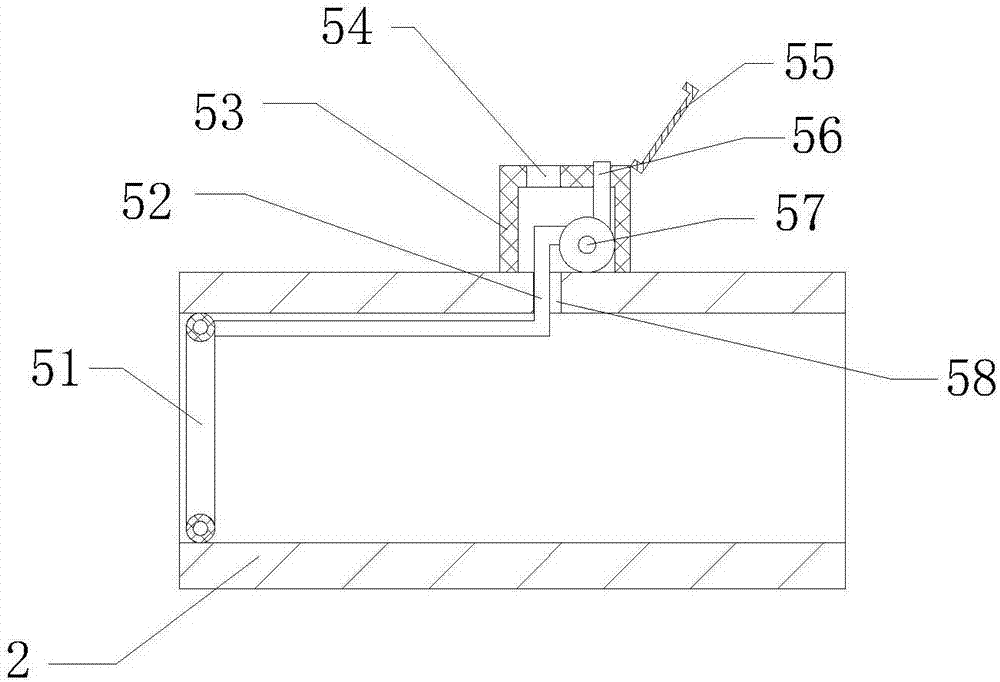

[0025] After the leakage repair of the pipeline in the cylinder 2 is completed, the user opens the cover body 55, and then exposes the air outlet 54 and the air inlet pipe 56 to the air, and then the user operates the fan 57, and the fan 57 works to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com