Laser strengthening device for antifriction bearing ring

A technology of laser strengthening and rolling bearings, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as stress relaxation, processing deformation, geometric deformation of bearing rings, etc., and achieve the effects of slowing down the relaxation rate, suppressing deformation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

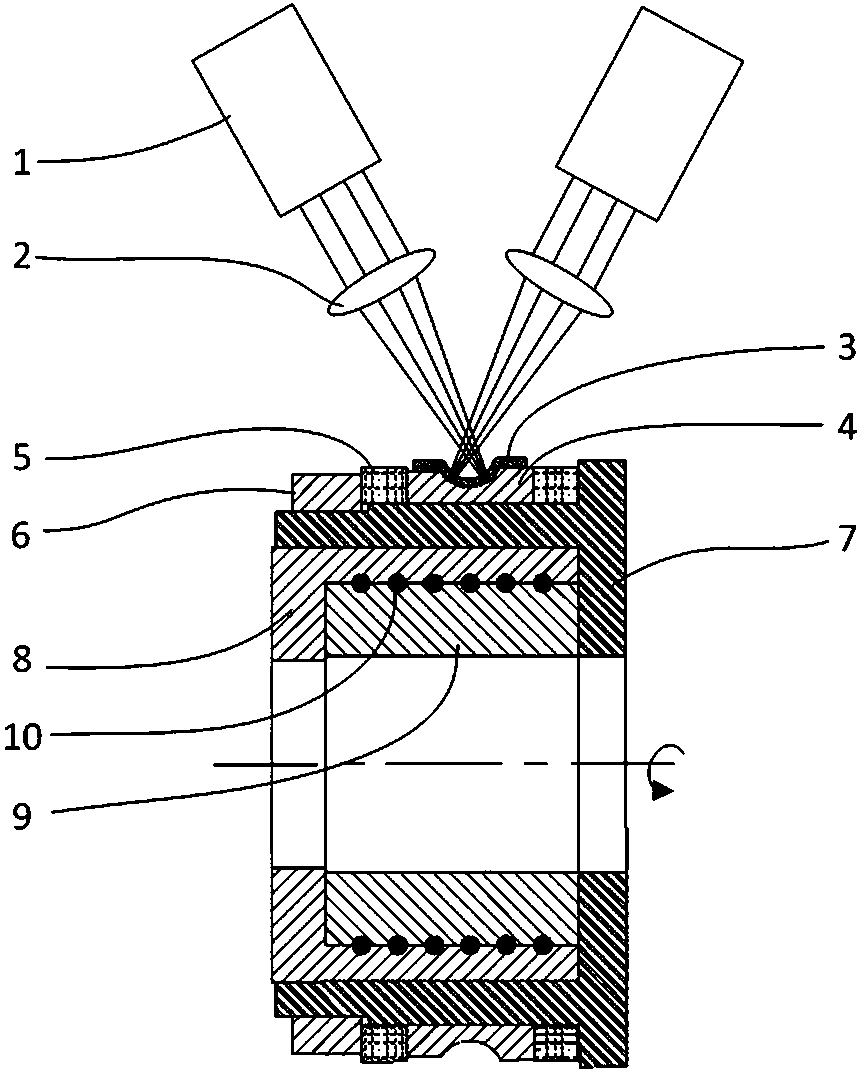

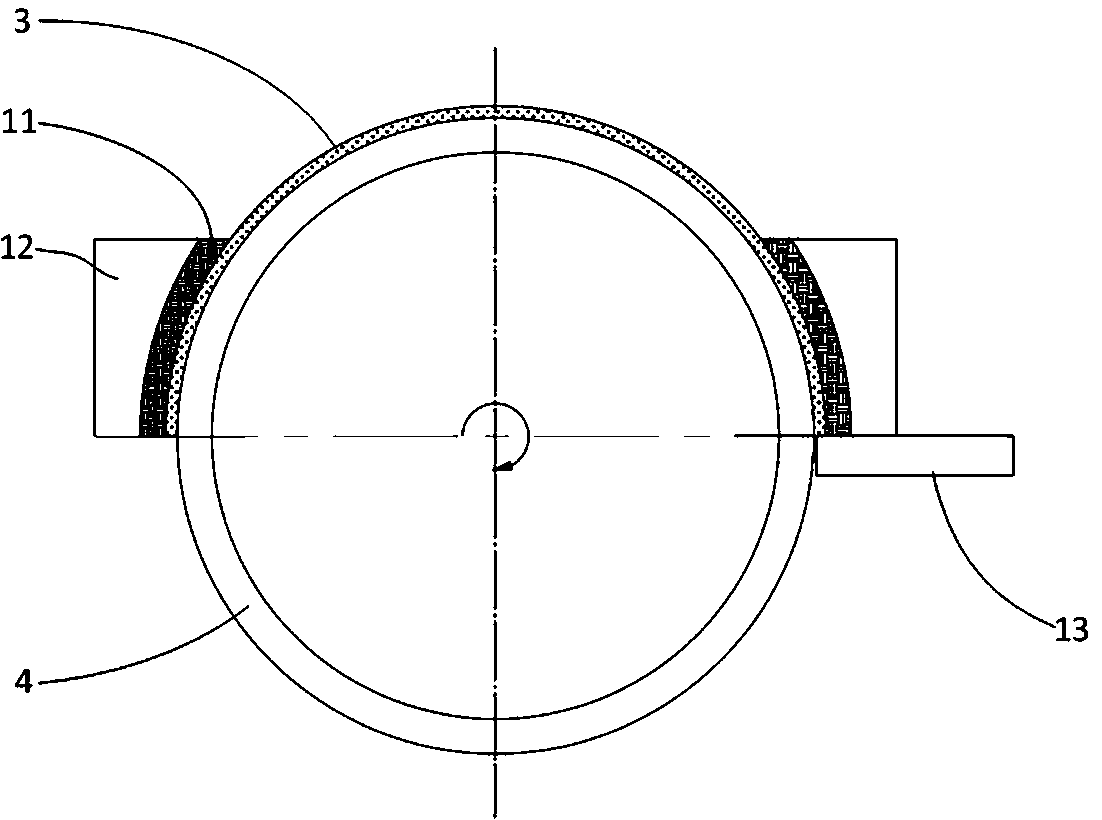

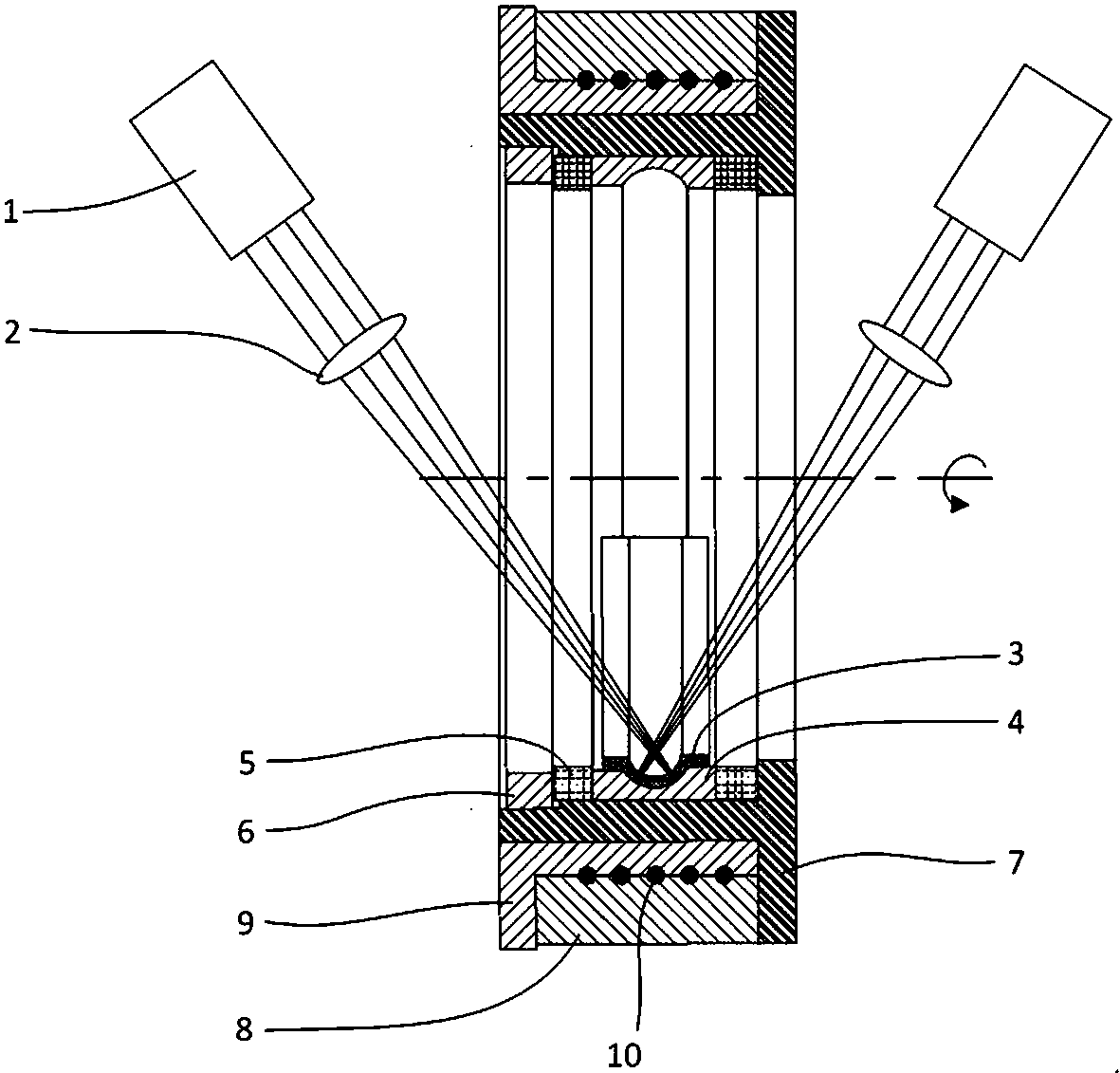

[0046] It can be understood that due to the limitation of the spot A of the laser emitted by the laser, it is impossible to strengthen the raceway of the bearing ring 4 at the same time, which will cause unbalanced stress distribution, that is, processing stress will be generated, and Therefore, the deformation of the bearing ring 4 will occur. Although the deformation is not large, for high-precision parts such as bearings (generally IT6 or IT7 precision), the laser-enhanced processing deformation is enough to make the geometric shape out of tolerance.

[0047] Regarding laser strengthening, the principle is to first coat a layer of black paint on the surface of the workpiece to form a black paint layer. The black paint layer has a better absorption effect on light, also known as the absorbing layer. When laser spot A falls on the absorbing layer, the part of the black paint covered by spot A is heated and vaporized to form plasma, which produces a burst, causing the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com