Polylactic acid-polypyrrole/silver composite antibacterial film and preparation method thereof

A compound antibacterial and polypyrrole technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve problems such as agglomeration and high cost of silver nanoparticles, and achieve the effect of enhancing antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a preparation method of polylactic acid-polypyrrole / silver composite antibacterial film, comprising the following steps:

[0033] S1, obtain PLA film;

[0034] S2. Preparation of AgNO 3 aqueous solution, put the PLA film on the AgNO 3 Soak and absorb in the aqueous solution to obtain the mixed solution;

[0035] S3, preparing Py monomer solution, pouring Py monomer solution into the mixed solution, Ag 3+ Initiating the oxidative polymerization reaction of the Py monomer on the surface of the PLA film to obtain a composite antibacterial film.

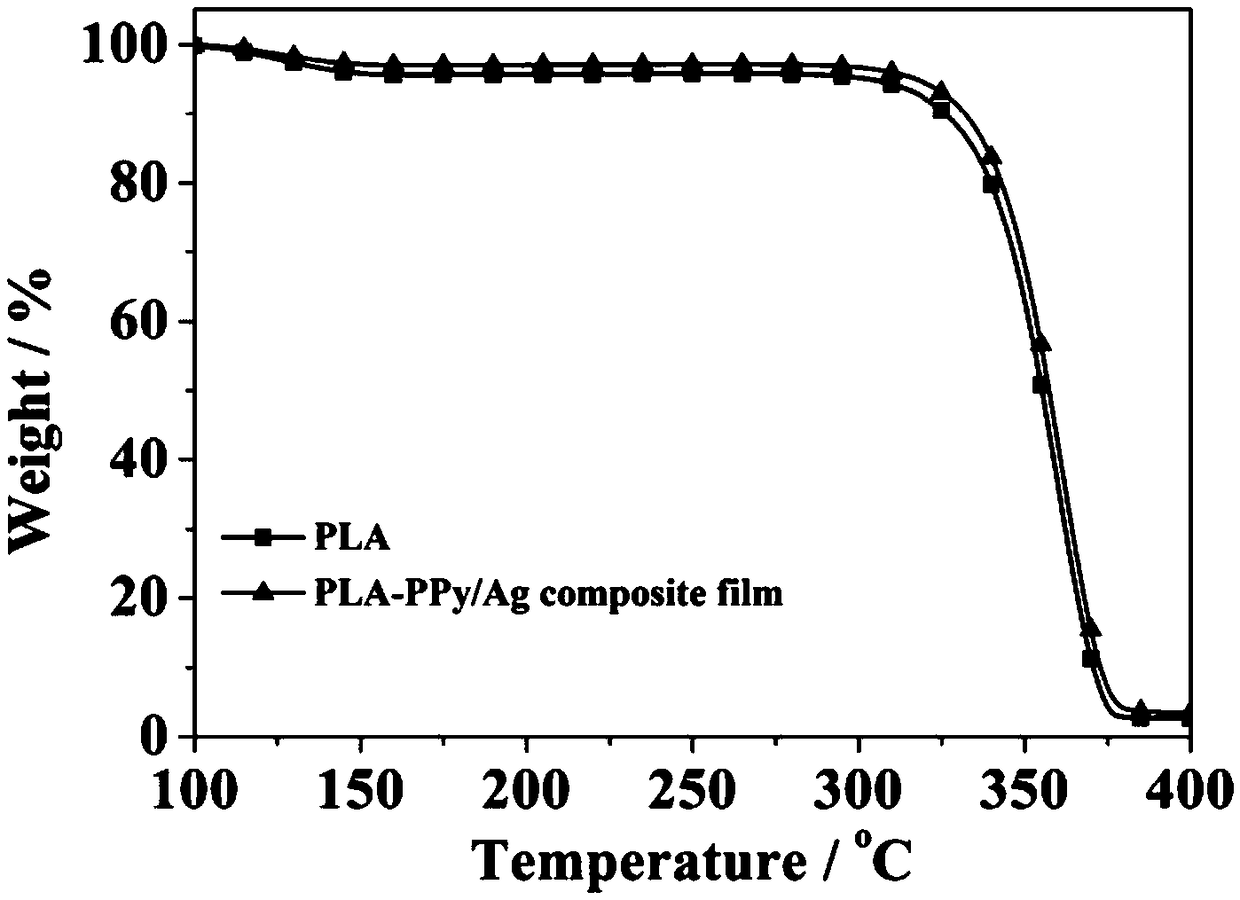

[0036] During the preparation process, the Ag + As an oxidizing agent, Py monomer is oxidized and polymerized to form PPy. In this process, Ag + It is reduced to form Ag simple substance and compound with PPy to form a composite antibacterial coating coated on the surface of PLA film to exert a dual antibacterial effect.

[0037] Further, in a preferred embodiment of the prese...

Embodiment 1

[0049] This embodiment provides a polylactic acid-polypyrrole / silver composite antibacterial film, which is prepared according to the following steps.

[0050] (1) Weigh 2g of PLA and dissolve it in 40ml of chloroform, stir magnetically at room temperature for 4h to dissolve completely, ultrasonicate for 30min until there are no obvious bubbles, transfer to a horizontally placed polytetrafluoroethylene mold and dry naturally to form a film. The length and width are 60mm×60mm.

[0051] (2) 0.068g AgNO 3 Dissolve in 40ml deionized water, stir well and sonicate for 5min to obtain AgNO 3 aqueous solution, the PLA film was immersed in AgNO 3 A mixed solution was obtained in an aqueous solution, and the temperature of the mixed solution was raised to 70° C., and the PLA film was adsorbed in the solution for 30 minutes.

[0052] (3) Take 0.625ml of Py and dissolve it in 40ml of deionized water, sonicate for 10min to fully dissolve it.

[0053] (4) Transfer the Py solution to the ...

Embodiment 2

[0056] This embodiment provides a polylactic acid-polypyrrole / silver composite antibacterial film, which is prepared according to the following steps.

[0057] (1) Weigh 2g of PLA and dissolve it in 40ml of chloroform, stir magnetically at room temperature for 4h to dissolve completely, ultrasonicate for 30min until there are no obvious bubbles, transfer to a horizontally placed polytetrafluoroethylene mold and dry naturally to form a film. The length and width are 60mm×60mm.

[0058] (2) 0.32g AgNO 3 Dissolve in 40ml deionized water, stir well and sonicate for 5min to obtain AgNO 3 aqueous solution, the PLA film was immersed in AgNO 3 A mixed solution was obtained in an aqueous solution, and the temperature of the mixed solution was raised to 80° C., and the PLA film was adsorbed in the solution for 30 minutes.

[0059] (3) Take 0.625ml of Py and dissolve it in 40ml of deionized water, sonicate for 10min to fully dissolve it.

[0060] (4) Transfer the Py solution to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com