Carton opening device

A carton and motor technology, applied in packaging, transportation and packaging, cutting and unsealing, etc., can solve problems such as increasing production costs, damaging raw materials, and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

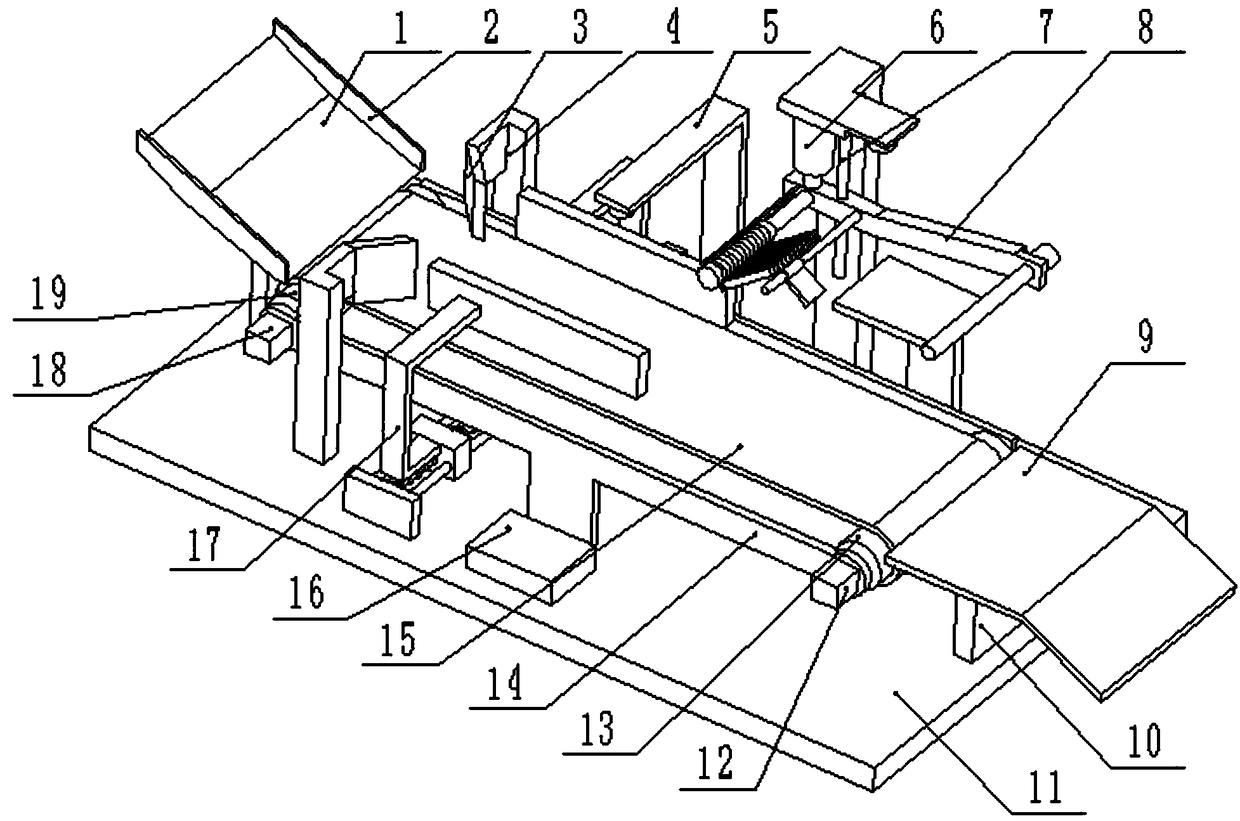

[0019] The present invention is realized through the following technical solutions:

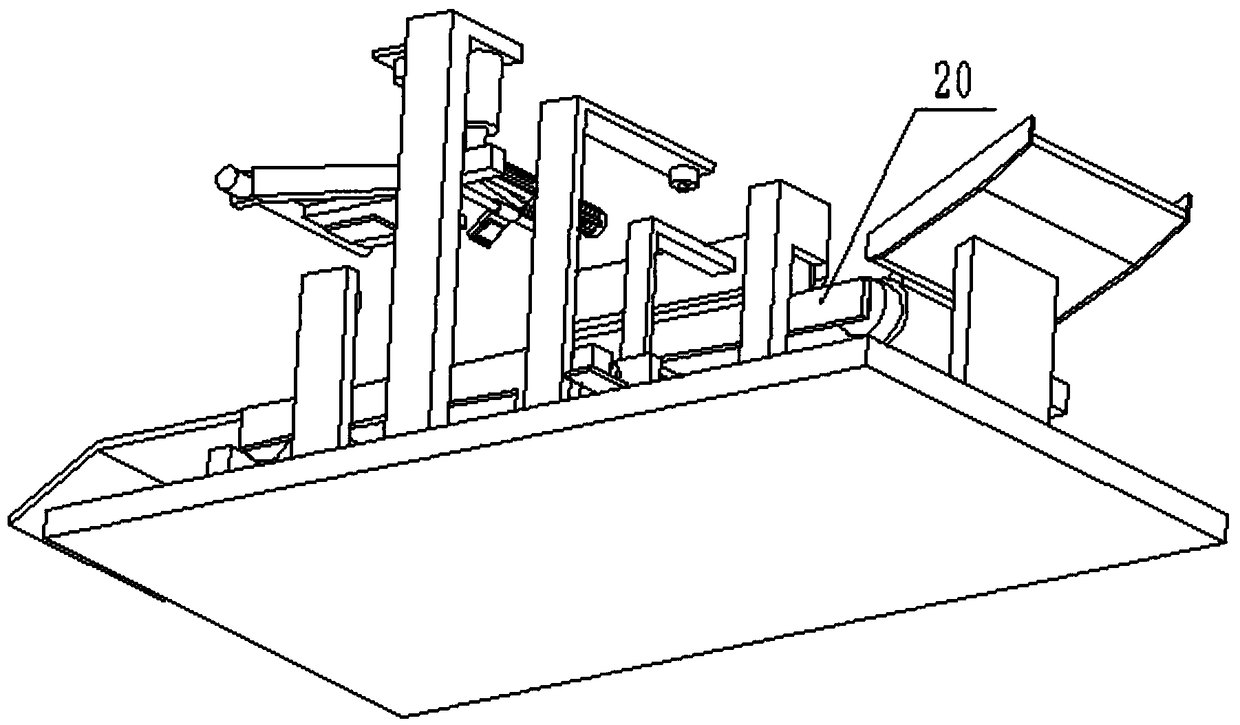

[0020]A carton unpacking device, comprising a feeding slide 1, a baffle plate 2, a first limit frame 3, a first bracket 4, a second bracket 5, a pneumatic cylinder 6, a first slide rail 7, an unpacking device 8, a Material slide plate 9, third bracket 10, base 11, first motor 12, first roller 13, motor base 14, conveyor belt 15, controller 16, alignment device 17, second motor 18, second roller 19, The fourth support 20, the first ultrasonic sensor 21, the second ultrasonic sensor 22, the second spacer 23, the fifth support 24, the third ultrasonic sensor 25 and the sixth support 26, the feeding slide 1 is fixed on the base 11, it is located on the left side of the second drum 19, and two of the baffles 2 are respectively installed on the left and right sides of the feed slide 1 to prevent the carton from falling off from the side of the feed slide 1, and the first limit frame 3 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com