Fan impeller rotation type double-station eight-axis linkage robot welding apparatus and method

A technology of robot welding and fan impeller, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., to reduce the quantity, improve the welding efficiency, and improve the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

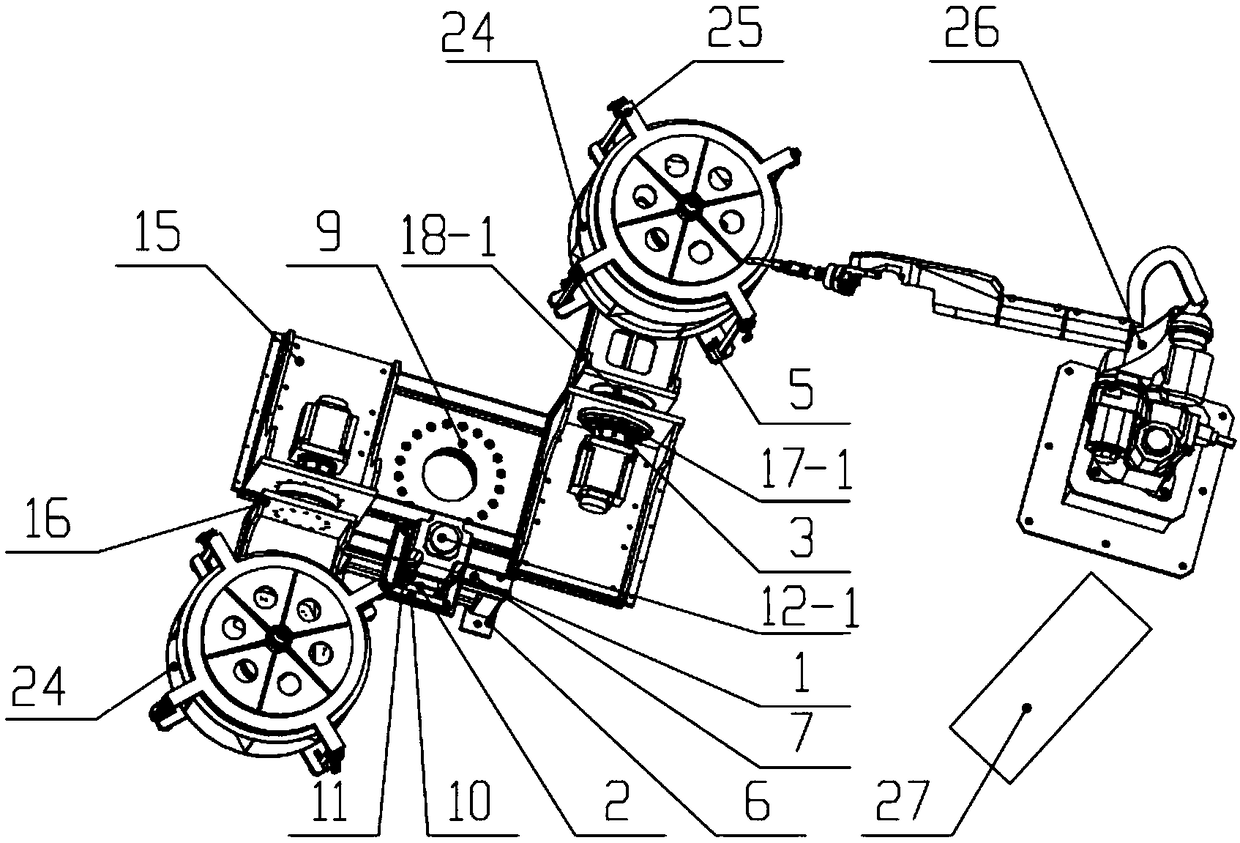

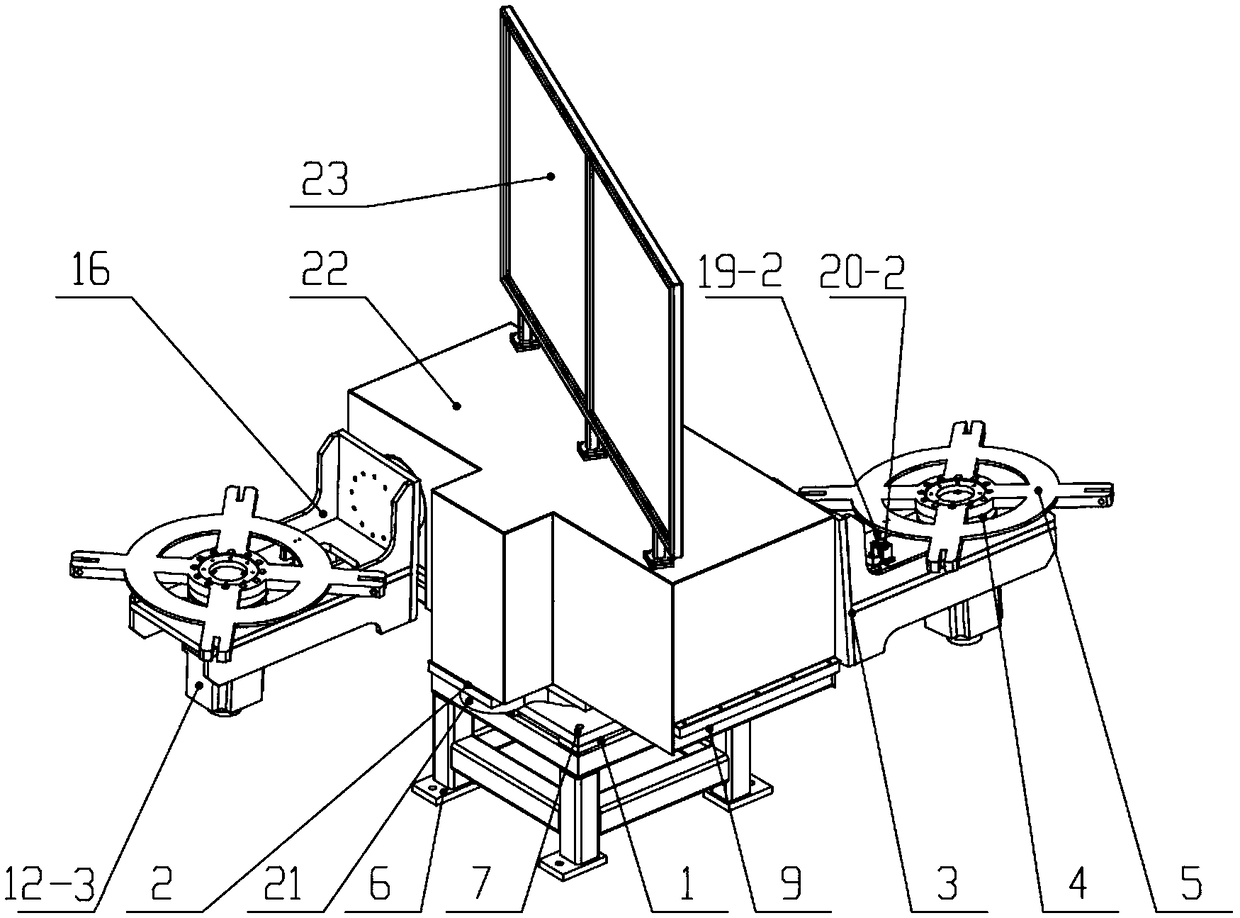

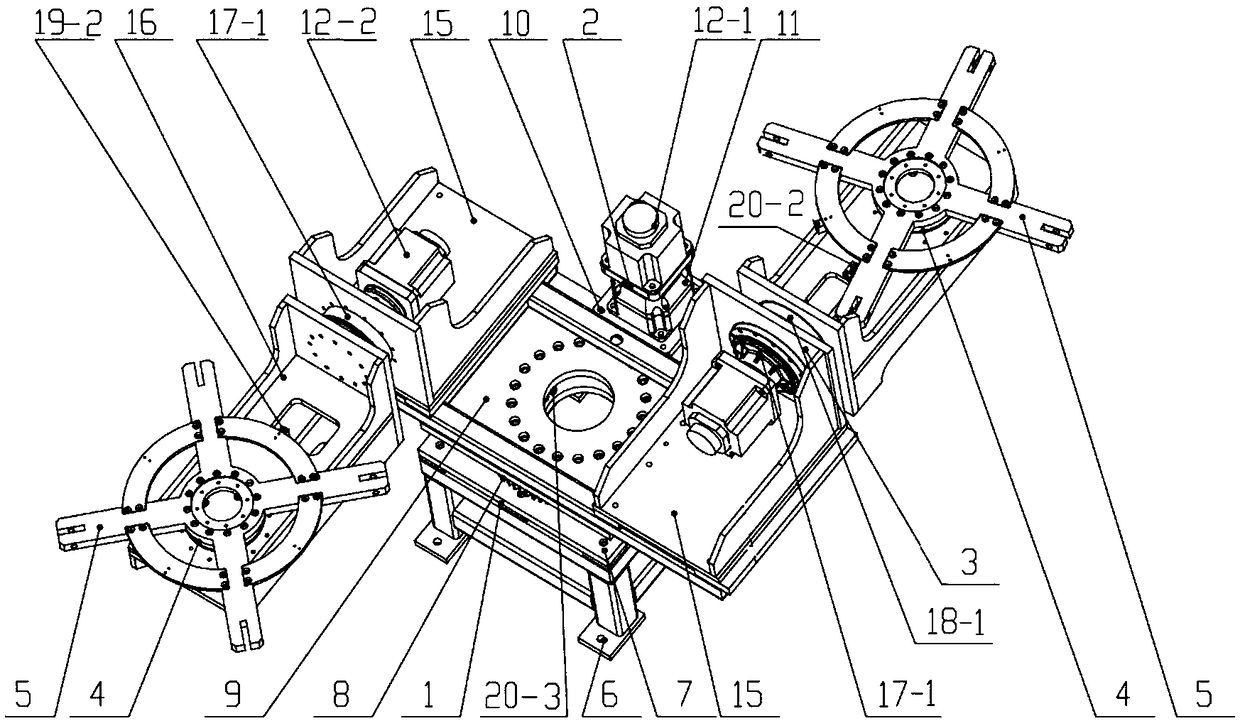

[0038] Such as Figure 1~6 As shown, the fan impeller rotary double-station eight-axis linkage robot welding equipment includes a six-axis joint welding robot 26 and a rotary double-station five-axis welding positioner; the rotary double-station five-axis welding positioner includes Base 1, rotary mechanism 2, turning mechanism 3, rotating mechanism 4 and welding platform 5. Two turning mechanisms 3 are arranged symmetrically about the center of the turning plate 9 of the turning mechanism 4, and the turning mechanism 4 simultaneously drives the two turning mechanisms 3 to rotate around the center of the turning plate 9; a turning mechanism 4 is arranged on the turning frame 16 of each turning mechanism 3, Each turning mechanism 3 drives a corresponding rotating mechanism 4 to turn over; each rotating mechanism 4 drives a welding platform 5 to rotate; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com