Structure used for cleaning exhaust duct online by means of dry ice

A dry ice and air duct technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of air duct damage, blockage of air ducts, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

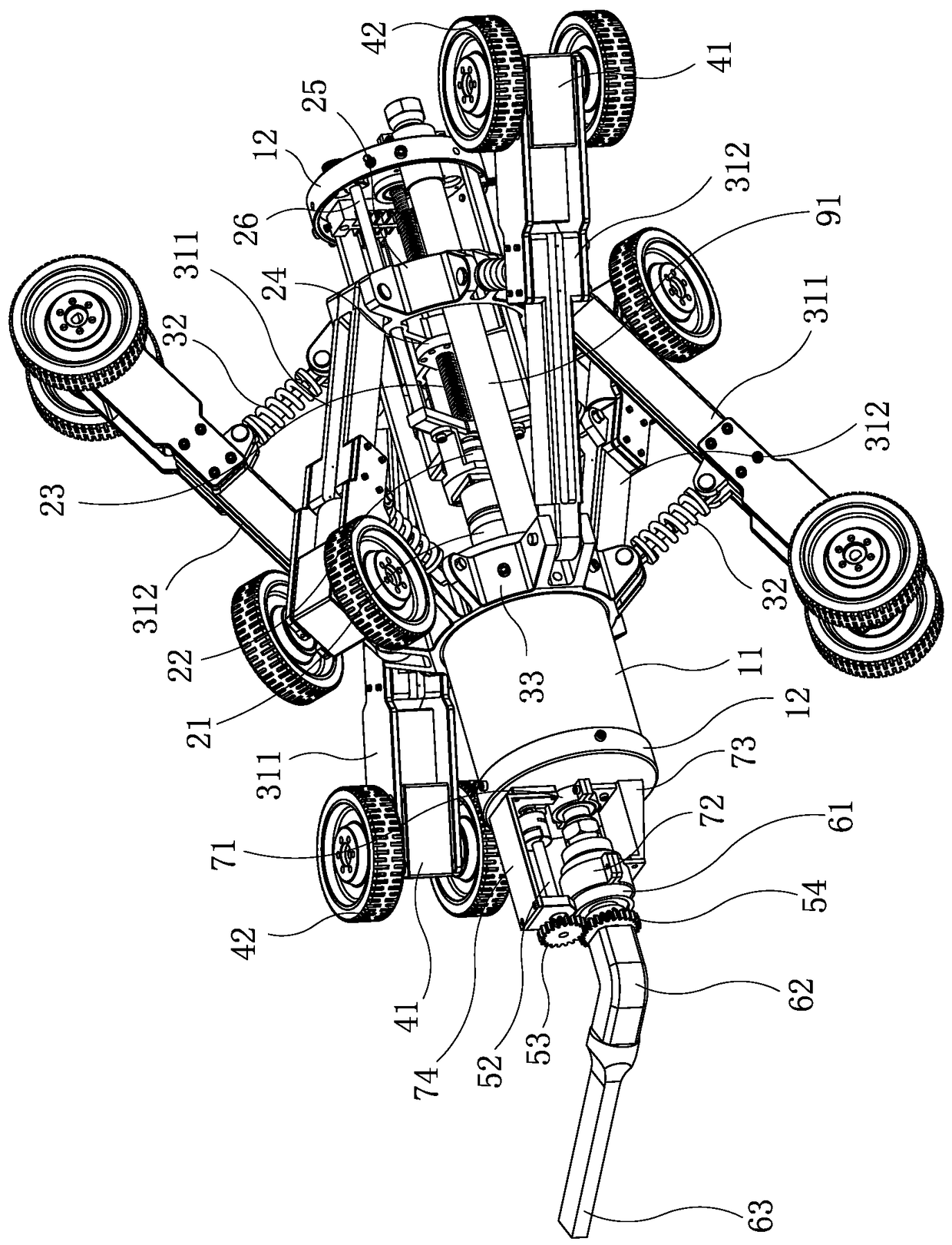

[0024] like Figure 1 to Figure 3 As shown, the present invention discloses a structure for cleaning an air duct online by using dry ice, which includes a crawling mechanism, a nozzle mechanism, an electrical control box 80 and a dry ice storage tank 90, wherein the dry ice storage tank 90 is connected to the nozzle mechanism through a dry ice delivery pipe 91 The electrical control box 80 is electrically connected to the crawling mechanism and the nozzle mechanism, and is used to control the forward and backward of the crawling mechanism, as well as the start and stop of the nozzle mechanism; the crawling mechanism is used to carry the nozzle mechanism and crawl in the air duct, so that the nozzle mechanism can carry out the air duct. cleaning work.

[0025] In the present invention, the electric control box 80 controls the crawling mechanism to crawl in the air duct. While crawling, the nozzle mechanism is activated. The dry ice in the dry ice storage tank 90 is transported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com