Interline nondestructive single-phase diverter and design method and control method thereof

A shunt, single-phase technology, applied to the field of lossless single-phase shunt between lines and the field of design and control, can solve the problems of no accurate current control method and large energy consumption of the shunt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

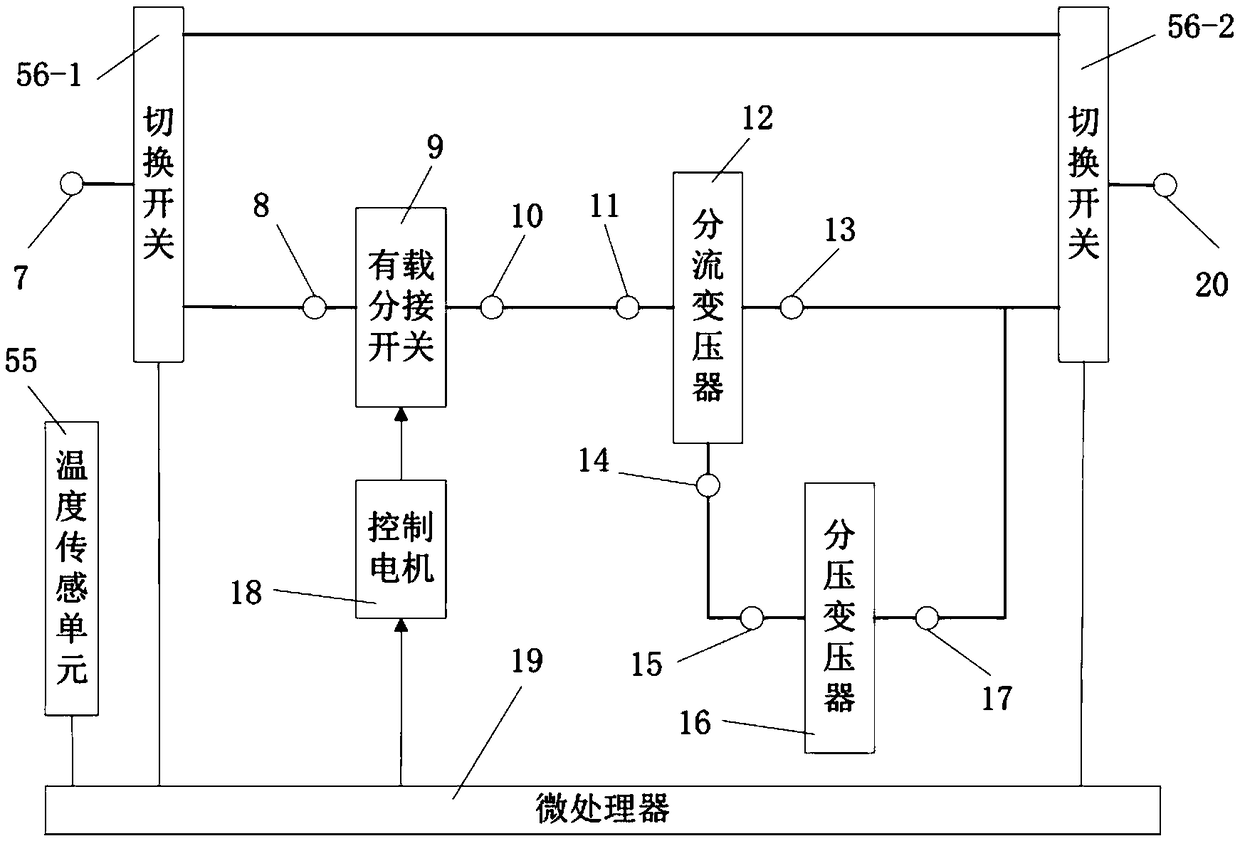

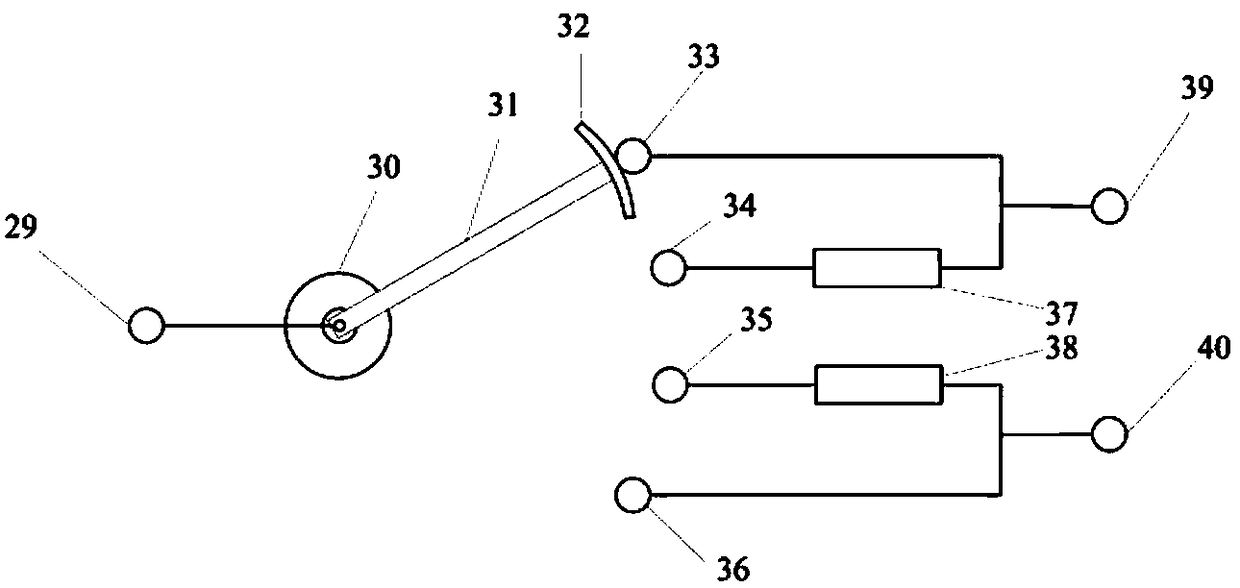

[0130] See attached picture.

[0131] The self-made heating wire with coaxial cable structure used in the present invention is the self-made heating wire disclosed in Chinese patents CN201810370549.8 and CN201811195033.0 applied by the inventor. Self-made heating wire structure such as Figure 8 As shown, it contains a self-made heating wire inner conductor 3, a self-made heating wire outer conductor 4, and an insulating material 60.

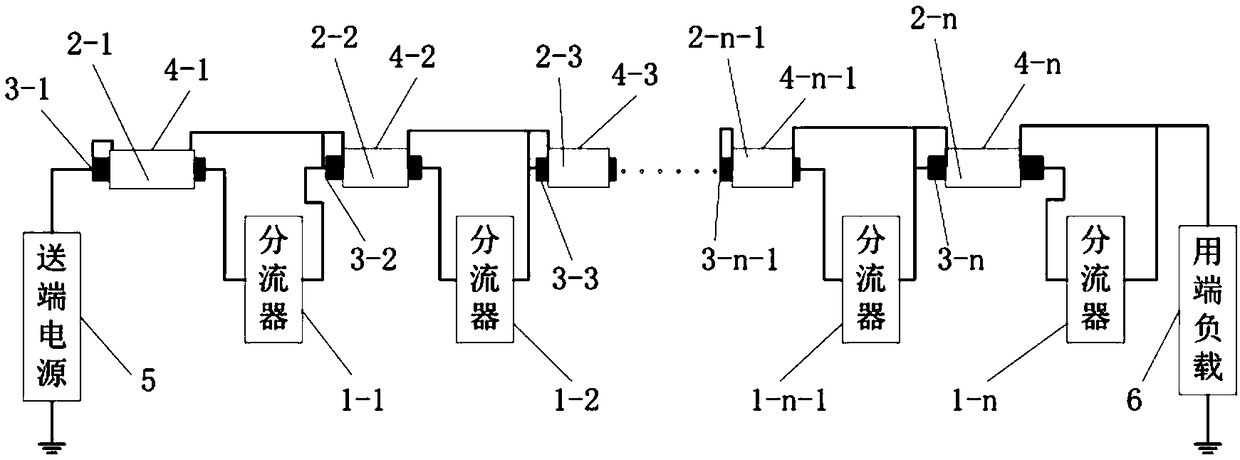

[0132] See attached figure 1 .

[0133] The shunt of the present invention is installed between two wires. The self-made heating wire is divided into several sections 2-1~2-n, the outer conductors 4-1~4-n of the adjacent self-made heating wires are short-circuited, and each section of the self-made heating wire is close to the inner conductor 3-1~2 of the power supply 5 at the sending end. 3-n and outer conductors 4-1 to 4-n are short-circuit connected, and the inner conductor close to the end of the electric load 6 is short-circuit connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com