Stepped overlapping core structure

A technology of iron core structure and core column, which is applied in the direction of transformer/inductor magnetic core, electrical components, transformer/inductor parts, etc., which can solve the problem of high transformer coil and oil tank height, insufficient utilization of transformer iron core, and overall Height becomes higher and other problems, to achieve the effect of reducing the overall height of the transformer, saving materials and reducing consumption, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

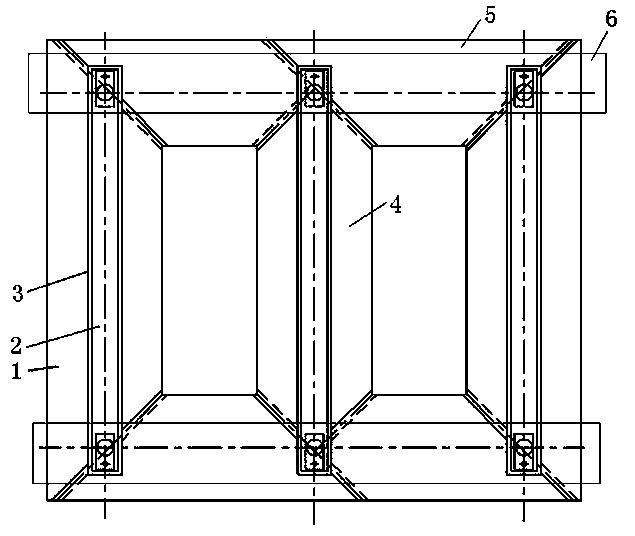

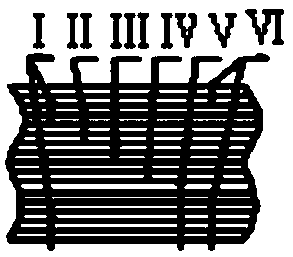

[0020] In this embodiment, as attached figure 1 , 2 As shown, the laminations in the core column 4 and the iron yoke 5 are composed of electrical steel strips 1, and the laminations are stacked in a six-step overlapping manner, and the six-step steps (Ⅰ, Ⅱ, Ⅲ, Ⅳ, Ⅴ, Ⅵ) The overlapping seams are staggered to reduce the magnetic resistance and loss.

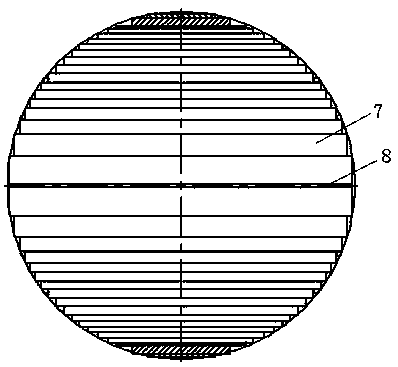

[0021] Refer to attached image 3 , the core column 4 is formed by superimposing fifteen-stage laminations, the width of the fifteen-stage laminations decreases from the middle to both sides, so that the cross-sectional area of the core column is a circular structure, and a core column oil channel 8 is set in the middle of the laminations for Heat dissipation.

[0022] Refer to attached Figure 4 , the iron yoke 5 is a cross-shaped structure formed by stacking two-stage laminations, and an iron yoke oil channel 9 is set in the middle of the laminations for heat dissipation. The two-stage laminations are divided into primary l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com