Limiting structure and pneumatic executing mechanism with same

A technology of pneumatic actuators and limit structures, applied in the field of control, can solve problems such as piston position changes, jitter, and difficult guarantees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

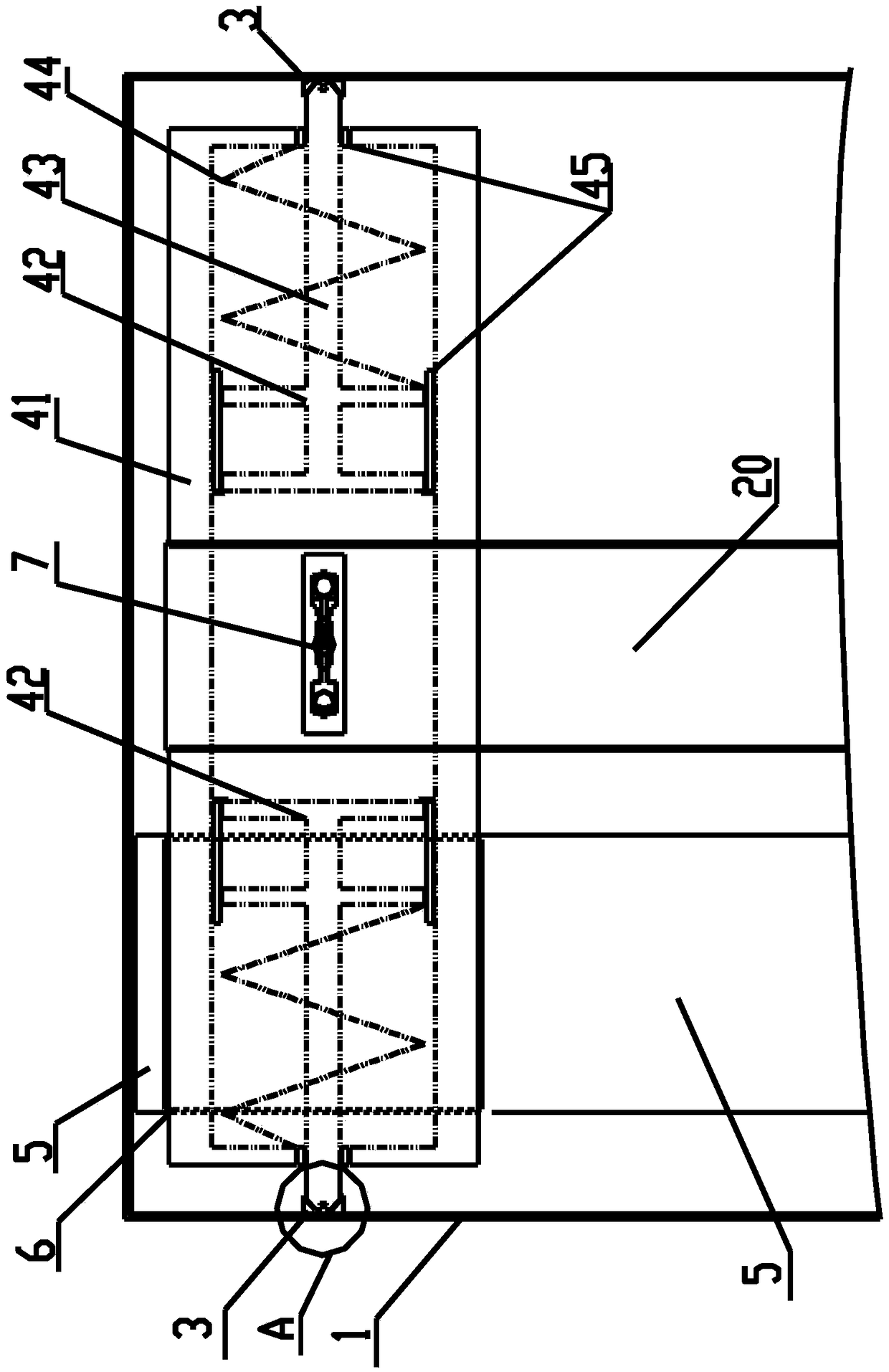

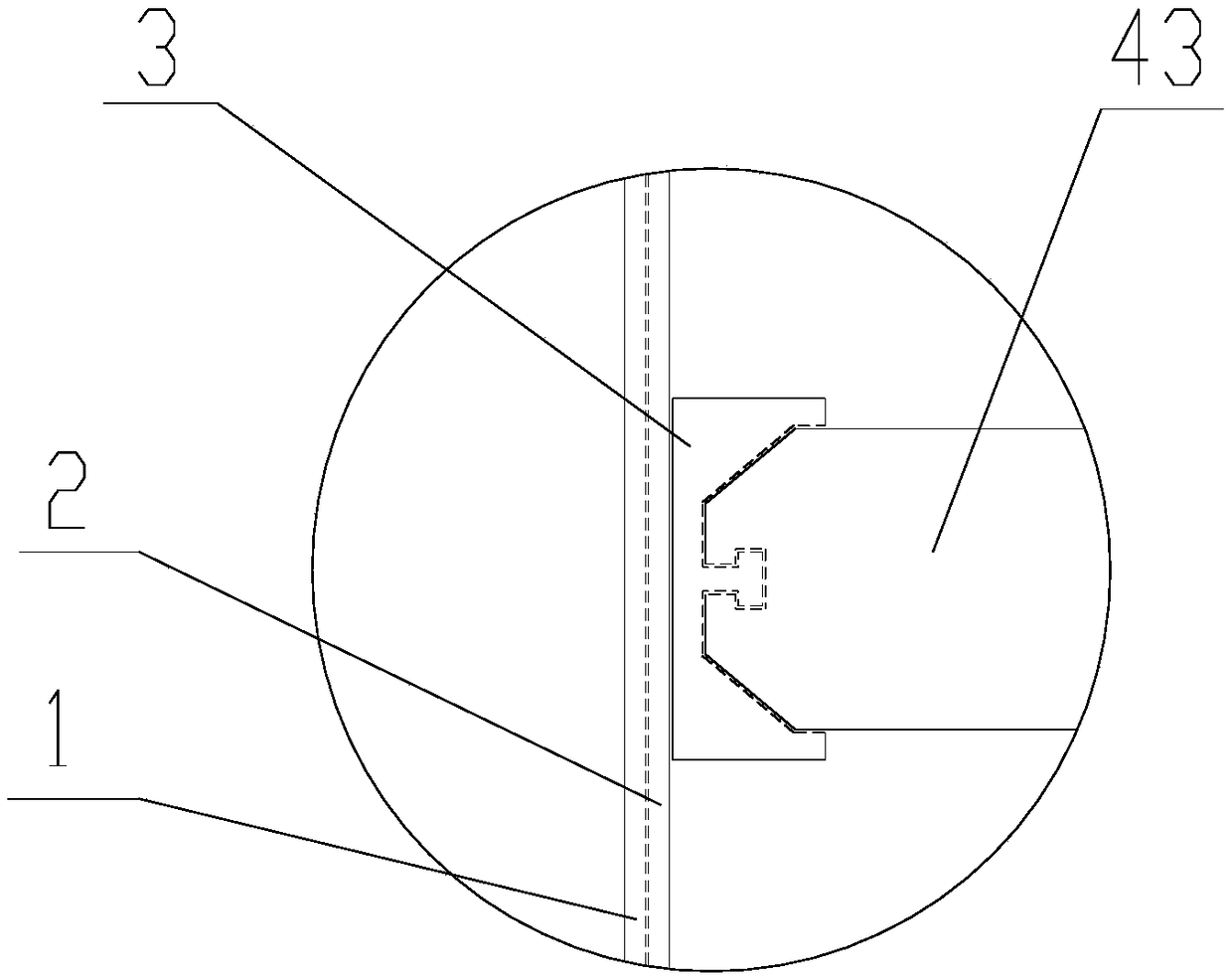

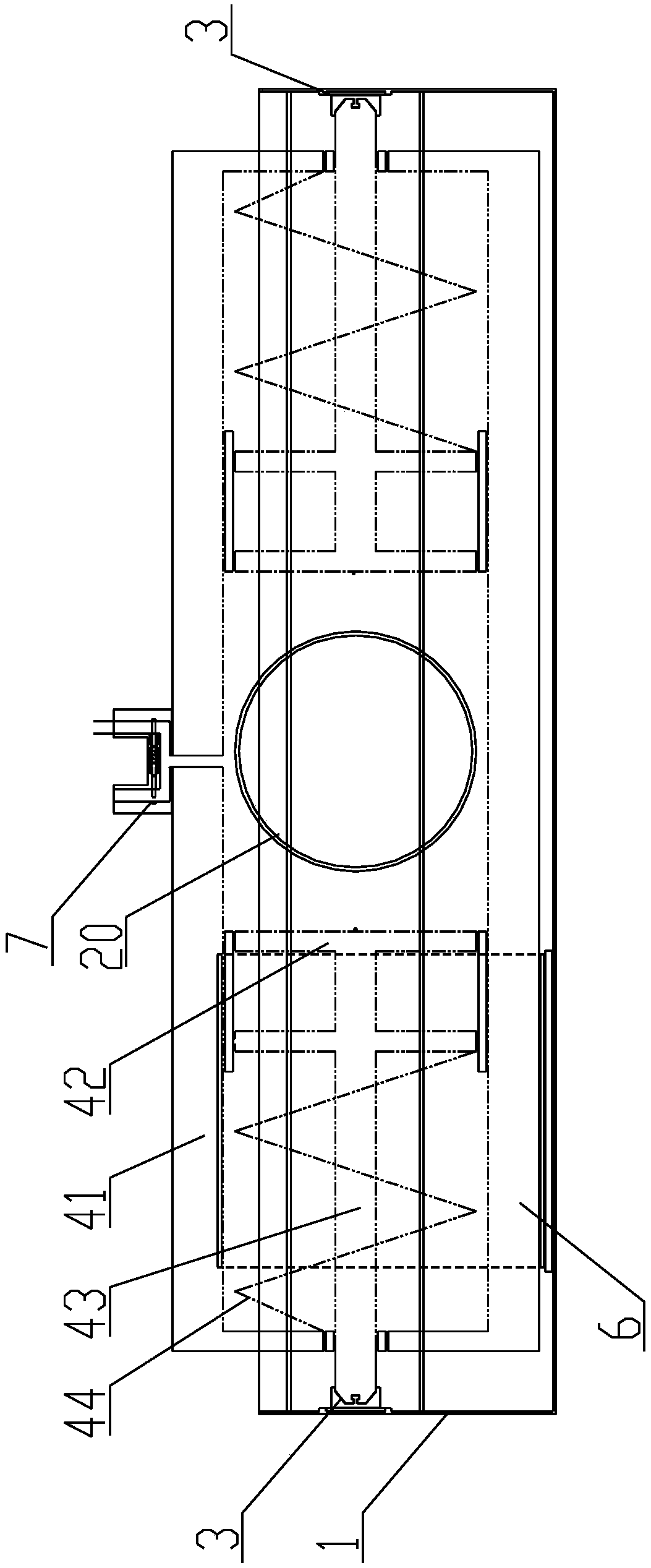

[0027] Please refer to figure 1 , figure 1 It is a structural schematic diagram of the assembly of a position-limiting structure and an actuating rod in the present invention; figure 2 for figure 1 The enlarged schematic diagram of A; image 3 for figure 1 another view of .

[0028] The pneumatic actuator includes an executive body. There are fluid passages and pistons inside the executive body. Valves are arranged on the fluid passages. The air source drives the piston to reciprocate between the first position and the second position. When the piston is at the first position, the interior of the executive body When the piston is in the second position, the valve inside the execution body is closed to meet the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com