Downhole device and production method suitable for non-killing well operation

A technology of killing wells and limiting devices, which is applied in wellbore/well components, earthwork drilling and production, and production fluids, etc. It can solve the problems of well control risks, impacts, and difficulty in accurately controlling dissolution time, so as to save labor and operating costs , improve production efficiency, and solve the effect of well killing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

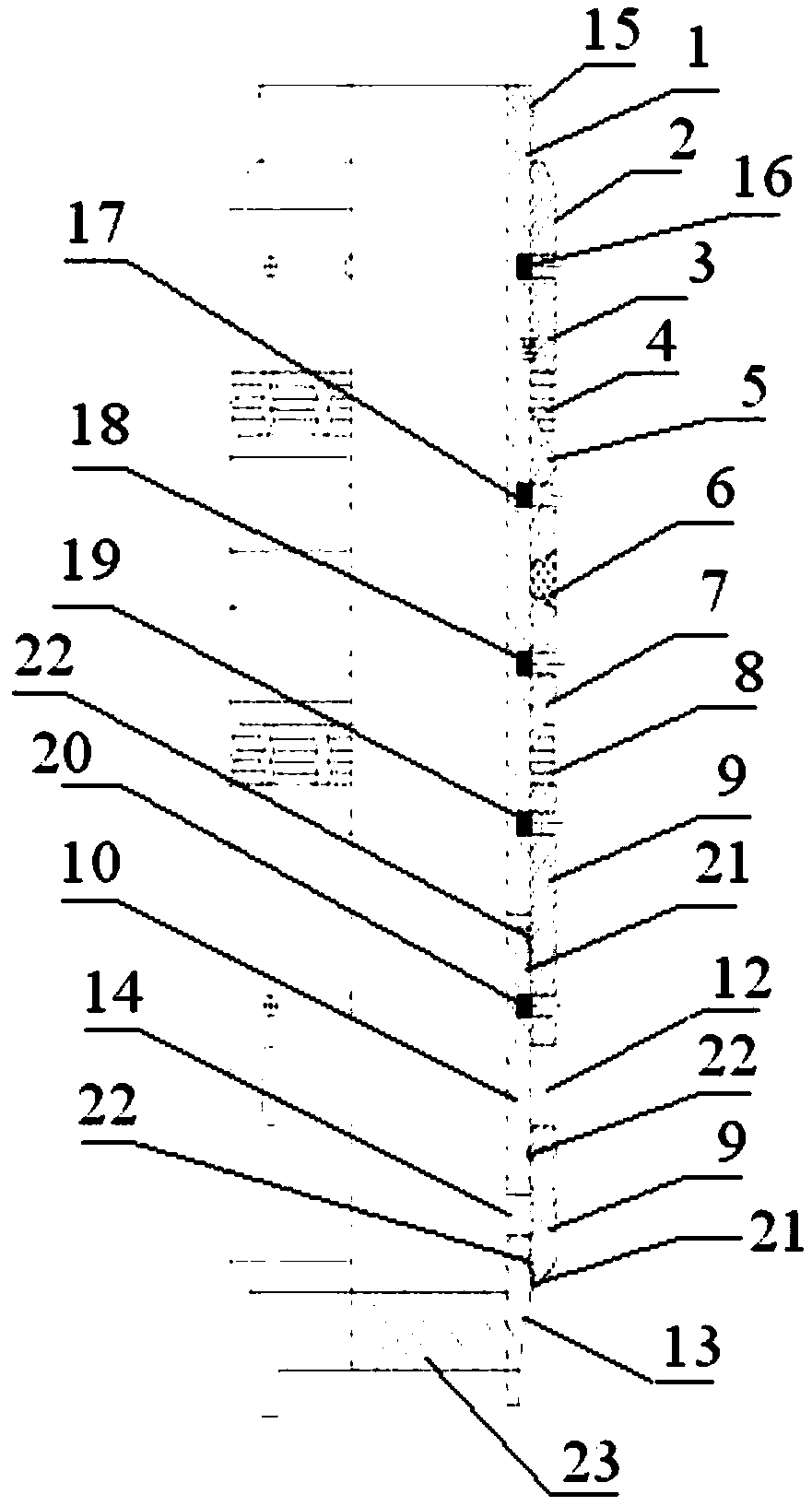

[0024] see figure 1 Shown:

[0025] The downhole device suitable for snubbing operation provided by the present invention includes an upper center pipe 1, an extrusion sleeve 2, a locking member 3, an upper slip 4, an upper cone 5, a rubber sleeve 6, a lower cone 7, The lower slip 8, the sleeve 9 and the lower central pipe 10, wherein the extrusion sleeve 2 is assembled on the upper part of the upper central pipe 1, the locking piece 3, the upper slip 4, the upper cone 5, the rubber sleeve 6, the lower cone The body 7 and the lower slip 8 are sequentially set under the extrusion sleeve 2, and the locking piece 3, the upper slip 4, the upper cone 5, the rubber tube 6, the lower cone 7 and the lower slip 8 are all sleeved on the On the upper central pipe 1, the sleeve 9 is sleeved on the lower end of the upper central pipe 1, the middle part of the sleeve 9 is provided with an outer flow groove 12, the lower central pipe 10 is inserted in the sleeve 9, and the lower part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com