A modification method for obstructing the installation of medium pipes in steel columns of expanded factory buildings

A technology for workshops and steel columns is applied in the field of reconstruction of medium pipelines that obstruct the installation of steel columns in expanded workshops. The risk of energy medium supply interruption, the effect of ensuring effective operation and saving plant space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

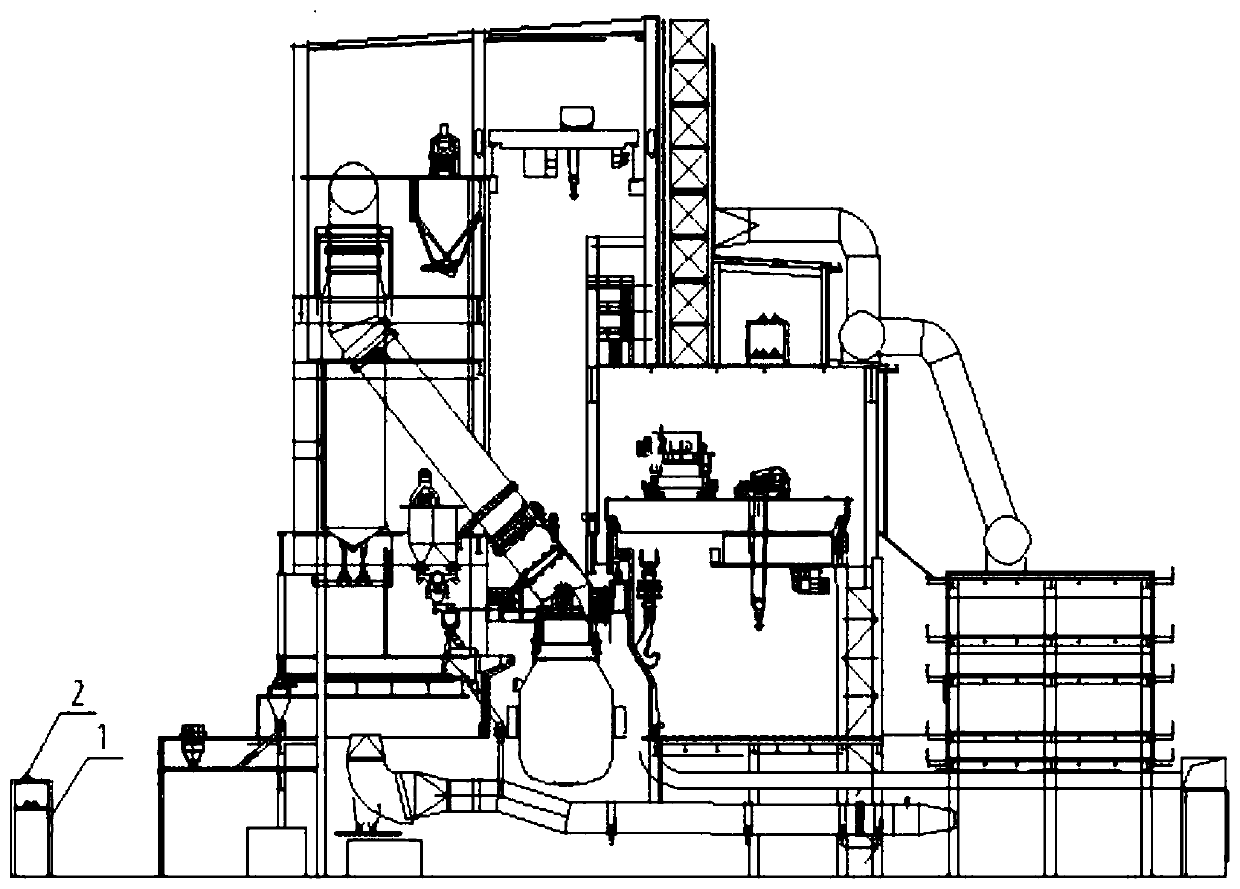

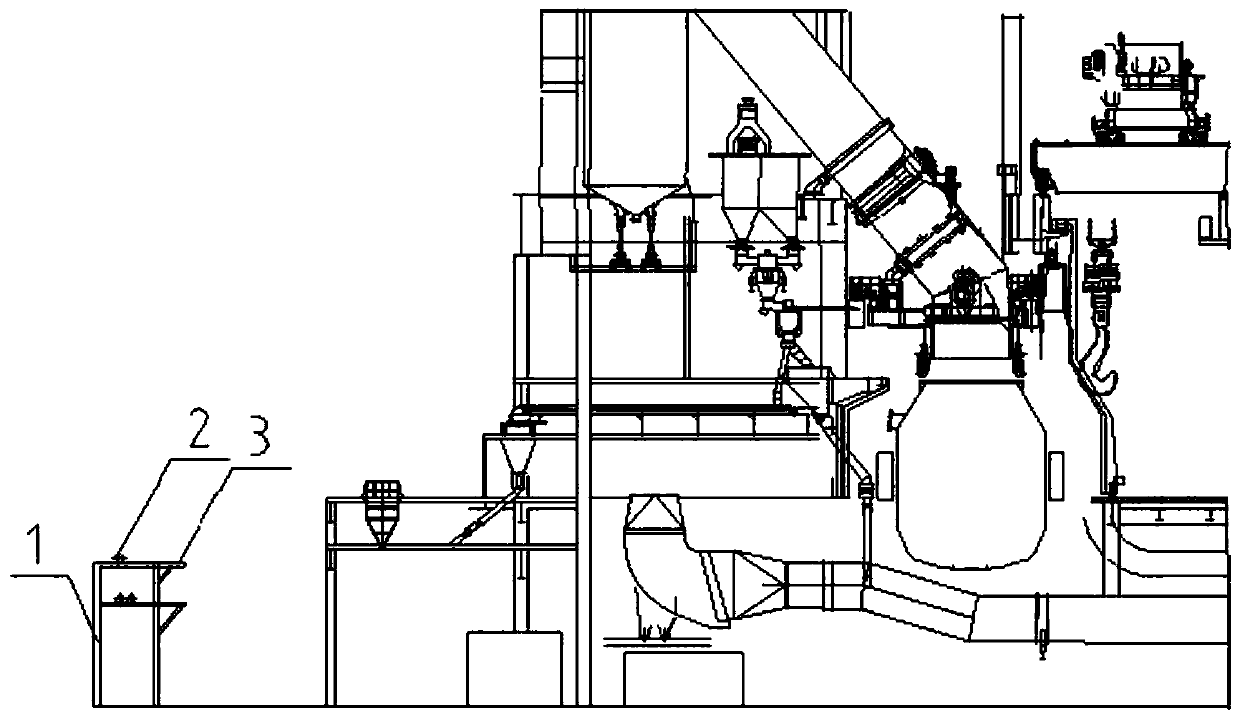

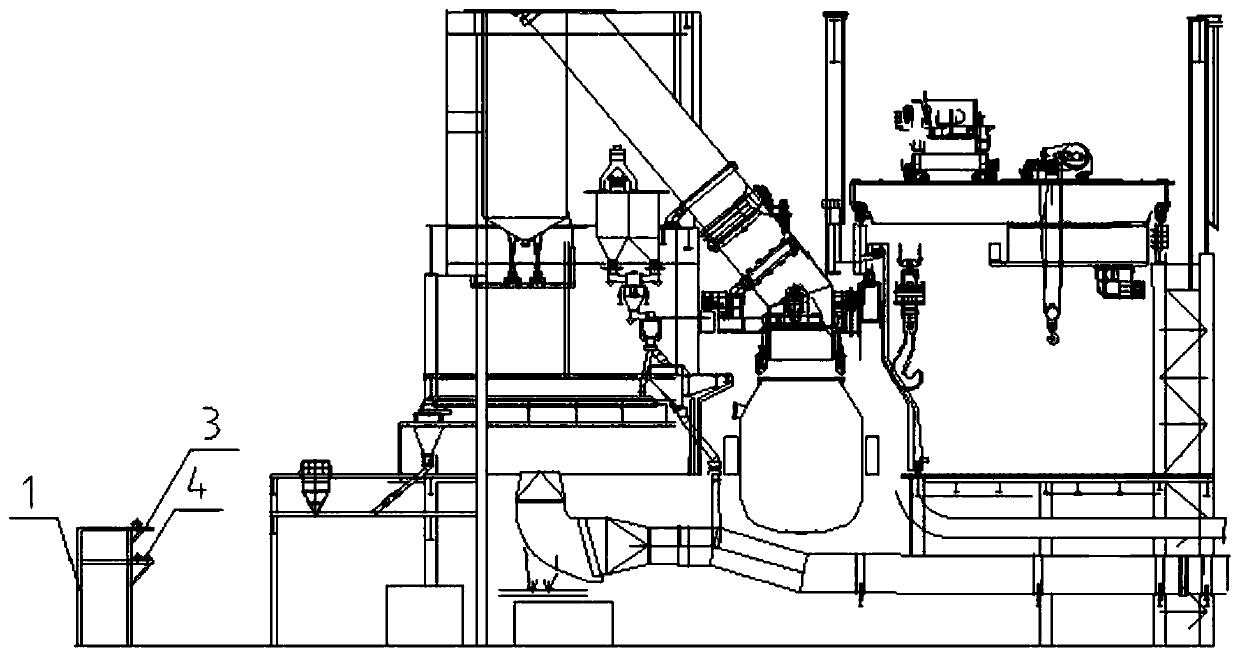

[0033] A 120t steel-making converter plant expansion project in Shandong, using a transformation method proposed by the present invention for medium pipes that hinder the installation of steel columns in the expanded plant to complete the plant expansion work.

[0034] As shown in the figure, the transformation structure that hinders the installation of medium pipes on the steel columns of the expanded factory building is mainly composed of the original pipe support 1, the medium pipe 2, the expanded pipe support 3, the reconstructed pipe 4, and the steel column 5 of the factory building.

[0035] Project overview, the total elevation of the H-column steel column in the extended factory building is 34.900m, the length of the lower column of the steel column lattice structure is 18.400m, and there is one column 300mm to the right of the center of the H-column steel column and 2 sticks medium pipeline, and the highest The central elevation of the medium pipeline is 19.200m. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com