A built-in guide cylinder

A technology with built-in guide oil cylinder and guide rod, applied in the direction of fluid pressure actuation device, mechanical equipment, etc., can solve the problem of unable to meet the space and conditions, and achieve the effect of reducing radial shaking, strengthening radial guiding effect, and reliable guiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

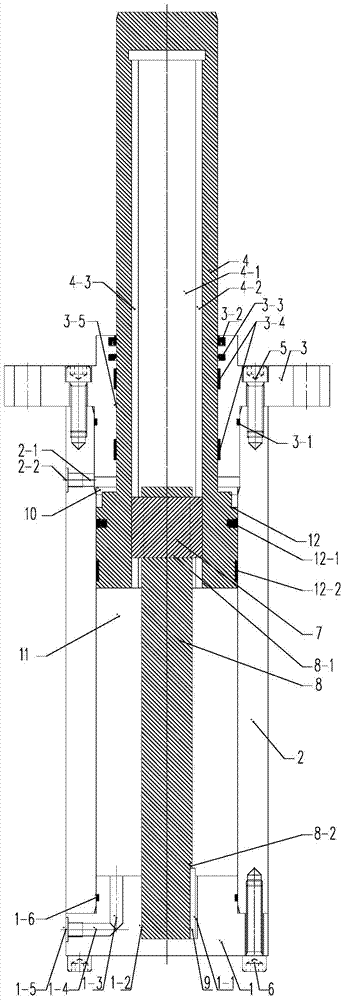

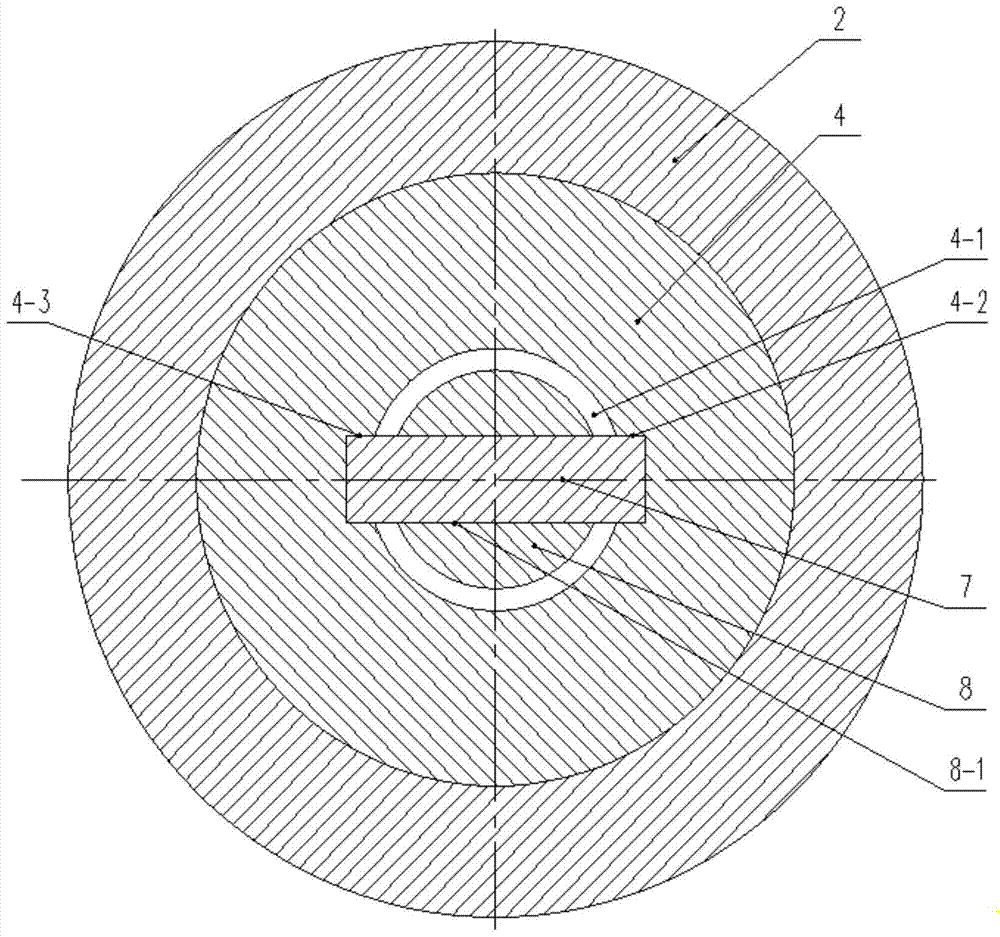

[0014] like figure 1 , figure 2 As shown, a built-in guide cylinder includes a lower end cover 1, a cylinder barrel 2, an upper end cover 3, a piston 12, a piston rod 4, an upper screw 5, a lower screw 6, a guide block 7, a guide rod 8, a key 9, oiling chamber 10 and lower oil chamber 11. The upper middle part of the lower end cover 1 is provided with a guide rod installation hole 1-2, the right side of the guide rod installation hole 1-2 is provided with a lower end cover keyway 1-1, and the upper left part of the lower end cover 1 is provided with the first oil passage hole of the lower end cover 1-3, the left side of the lower end cover 1 is provided with the lower end cover oil inlet 1-5 and the lower end cover second oil hole 1-4, the lower end cover oil inlet 1-5 passes through the lower end cover second oil hole 1- 4. The first oil passage hole 1-3 of the lower end cover communicates with the lower oil chamber 11 of the oil cylinder, and the lower end cover sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com