Compensation type aeration turning-free aerobic fermentation device

An aerobic fermentation and fermentation device technology, which is applied in animal husbandry wastewater treatment, biological sludge treatment, etc., can solve the problems of prolonged fermentation period, low temperature of the heap, unfavorable water vapor, etc., and achieves improved fermentation effect and uniform aeration. , the effect of improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

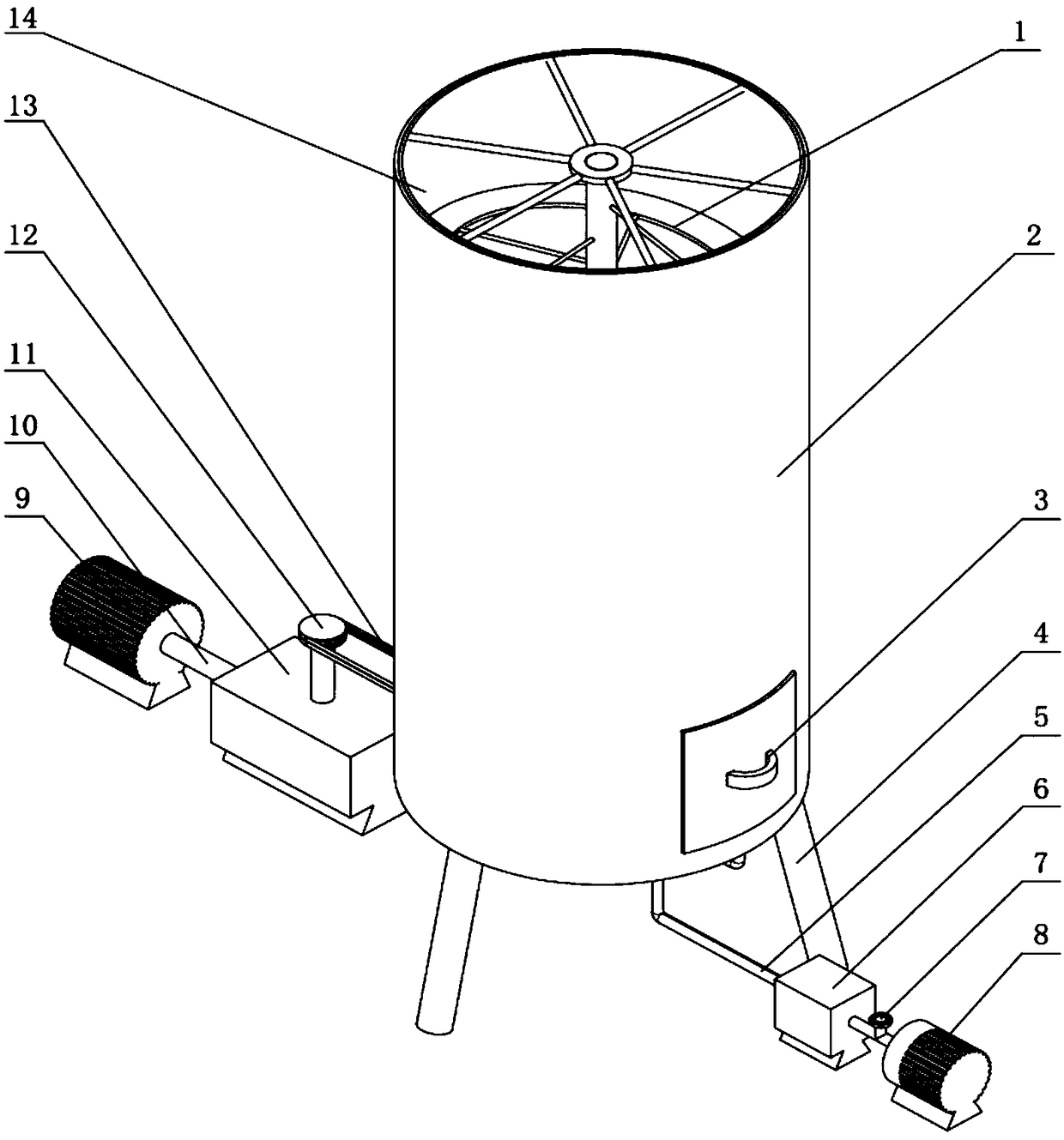

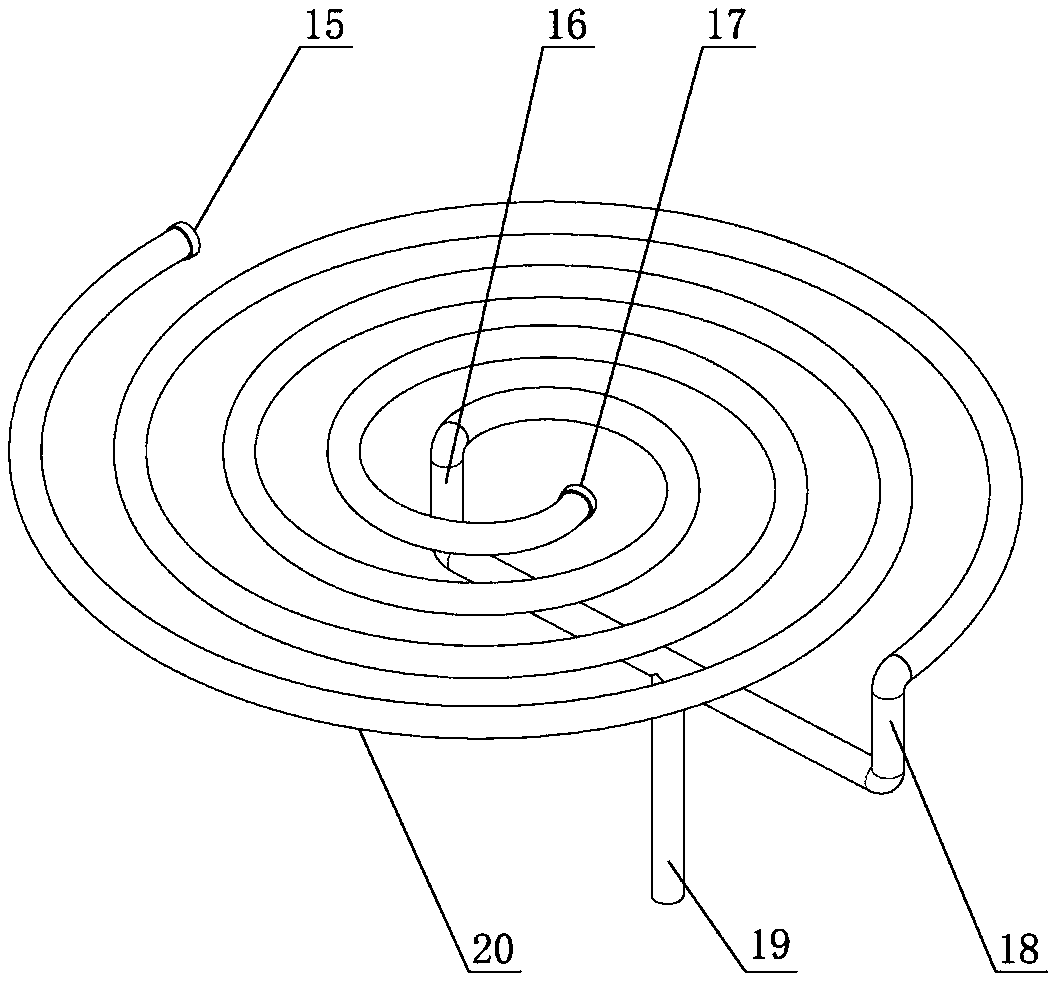

[0041] The invention provides a compensatory aeration-free aerobic fermentation device, which includes a stirring device 1, a fermentation cylinder 2, an aeration device, a power device and an air intake device, wherein the stirring device 1 and the aeration device are both Set inside the fermentation cylinder 2, the fermentation device also includes a plurality of outriggers 4, which support the device so that it can be placed on the ground;

[0042] The power unit includes a motor 9, a transmission shaft 10, a reduction box 11, a first pulley 12 and a belt 13;

[0043] The air intake device includes a blower fan 8 and a total air intake pipe 5 .

[0044] Specifically, the top of the fermentation cylinder 2 is an open structure, the purpose is to discharge th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com