The storage tank structure of the conductive silver glue raw material resin powder

A technology of conductive silver glue and storage barrels, which is applied in the direction of anti-rot containers, impact-sensitive items, types of packaging items, etc., can solve the problems of affecting food processing hygiene and safety, mildew, etc., and achieve simple structure and prevent mildew , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Various exemplary embodiments of the present invention will now be described in detail. The detailed description should not be considered as a limitation of the present invention, but rather as a more detailed description of certain aspects, features and embodiments of the present invention.

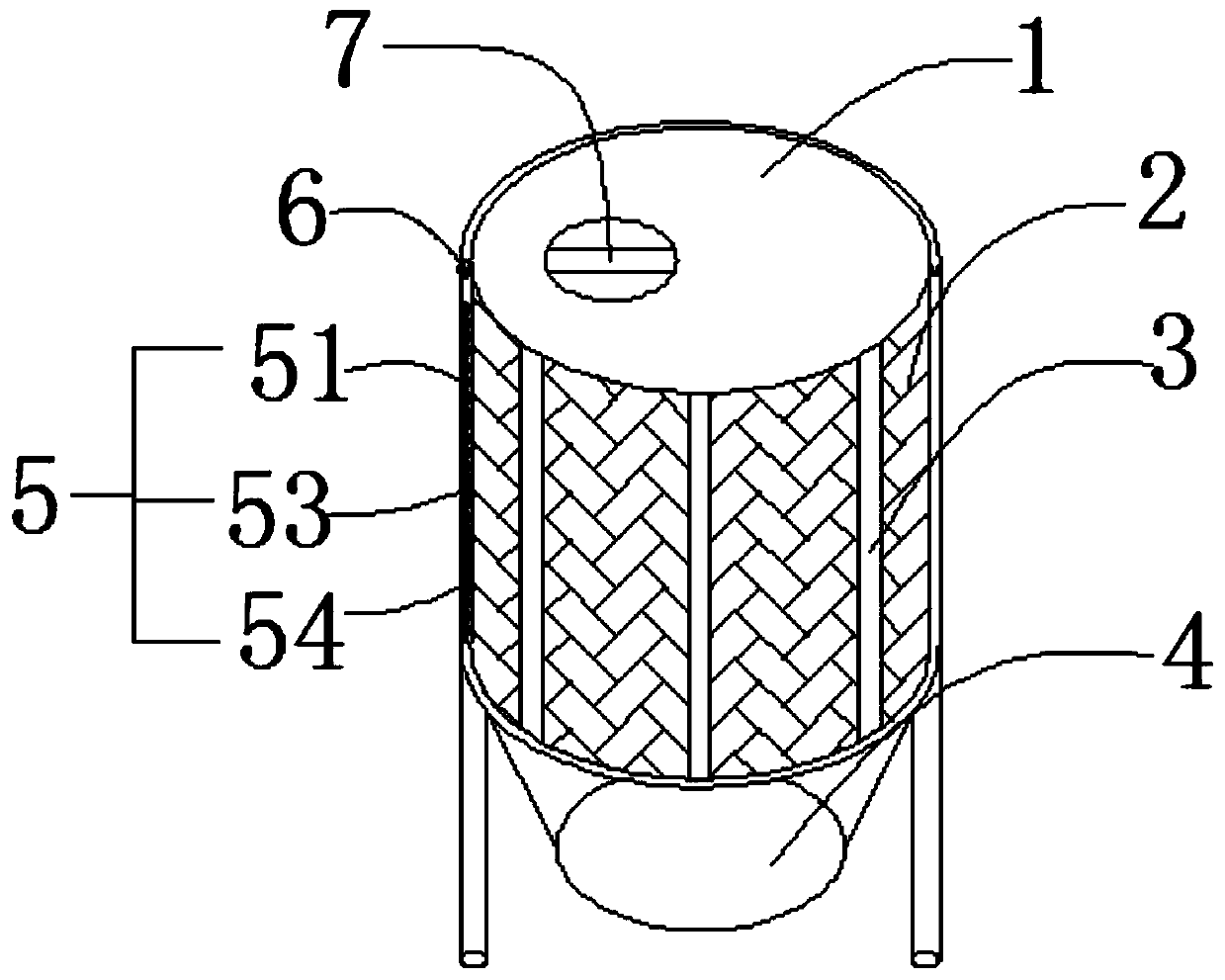

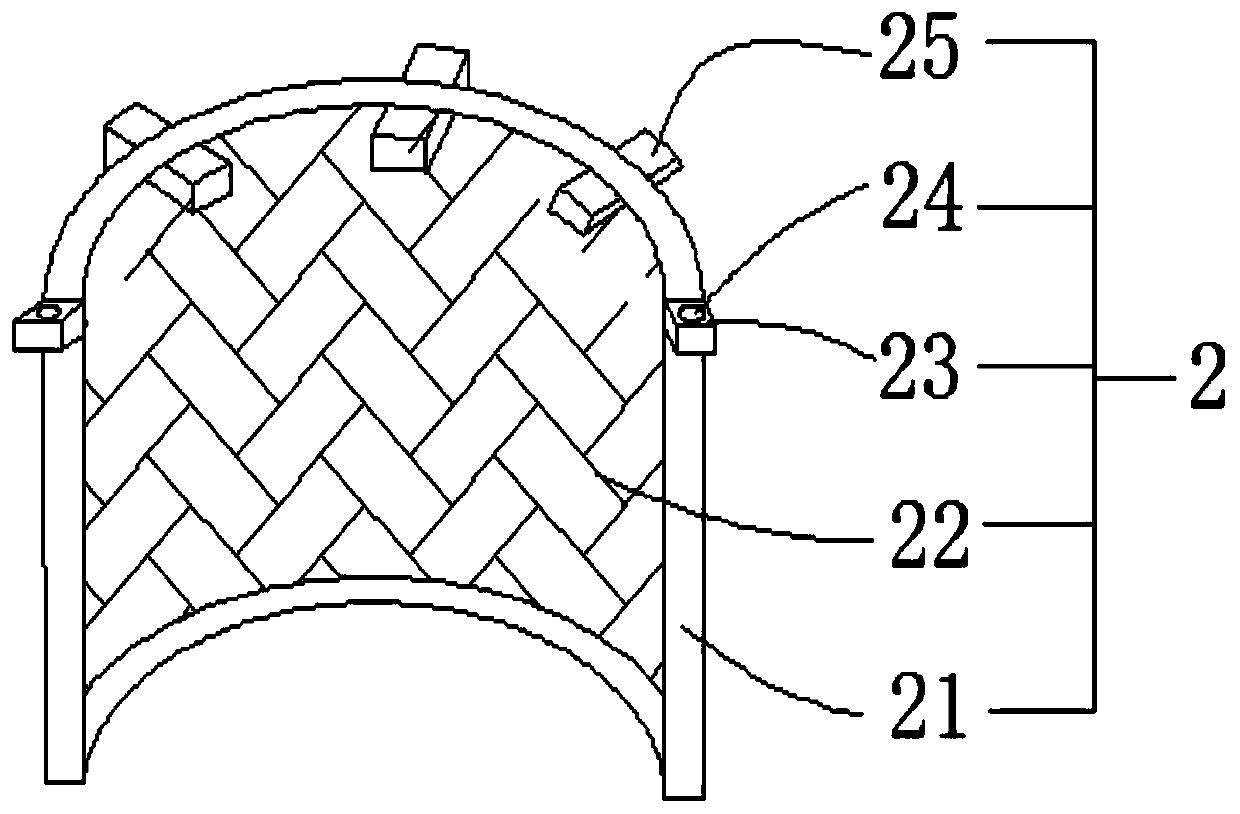

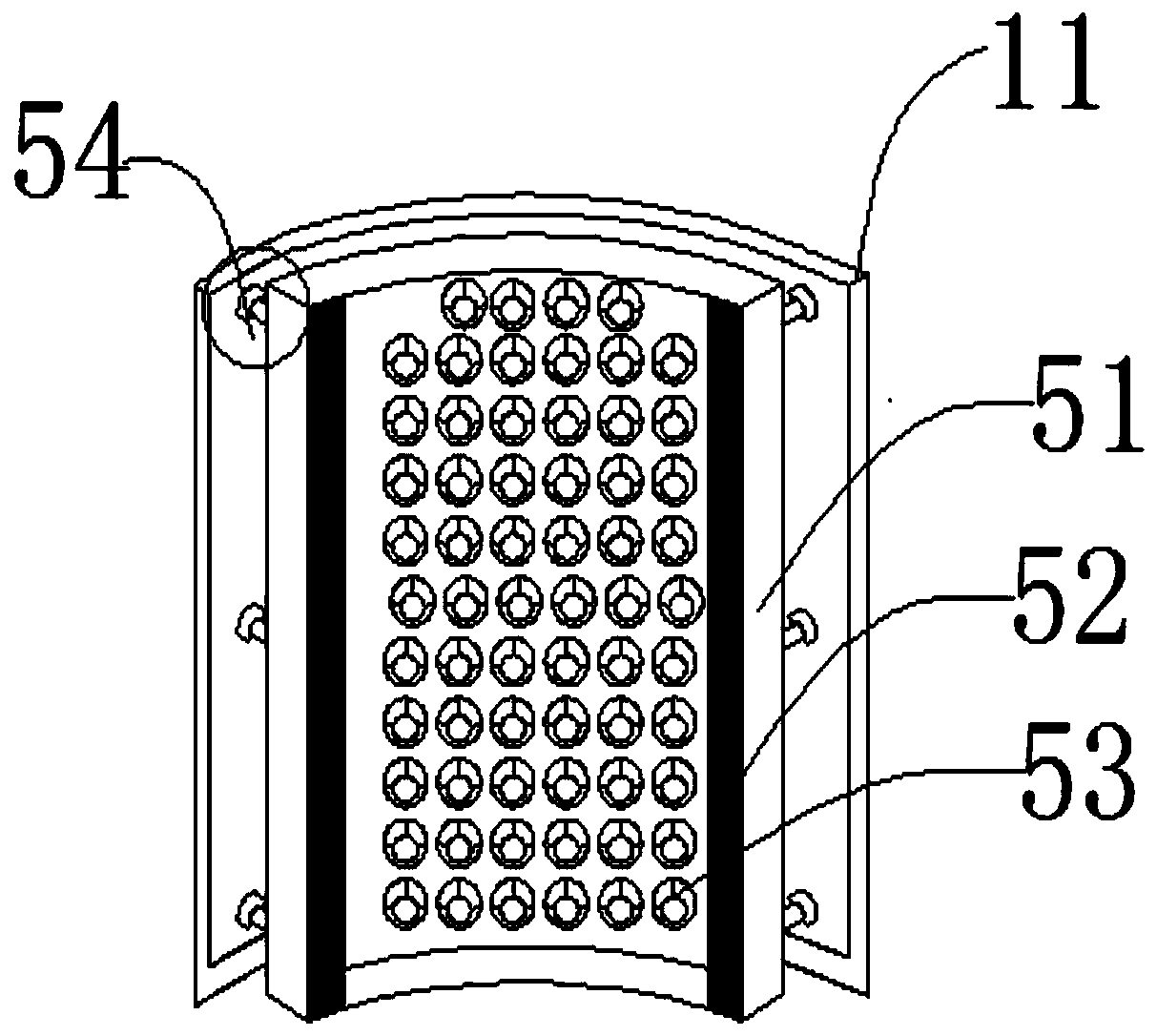

[0023] see Figure 1-7 , the present invention provides a technical solution, a storage barrel structure of a novel conductive silver glue raw material resin powder, including a storage barrel 1, the upper end surface of the storage barrel 1 is provided with a feed port 7, and the bottom of the lower end is provided with A discharge port 4, a filter unit 2 is installed on the side of the storage tank 1, and a plurality of electromagnetic vibration units 5 are arranged on the side of the filter unit 2, and a plurality of the vibration units 5 are arranged in the storage tank 1 On the cavity wall 11; the filter unit 2 includes a fan-shaped filter frame 21, the fan-shaped filter fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com