Spray head lifting locating method

A technology of lifting positioning and nozzles, which is applied in power transmission devices, printing, transfer materials, etc., can solve the problems of low positioning accuracy and processing difficulty, and achieve the effects of high safety, low cost and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

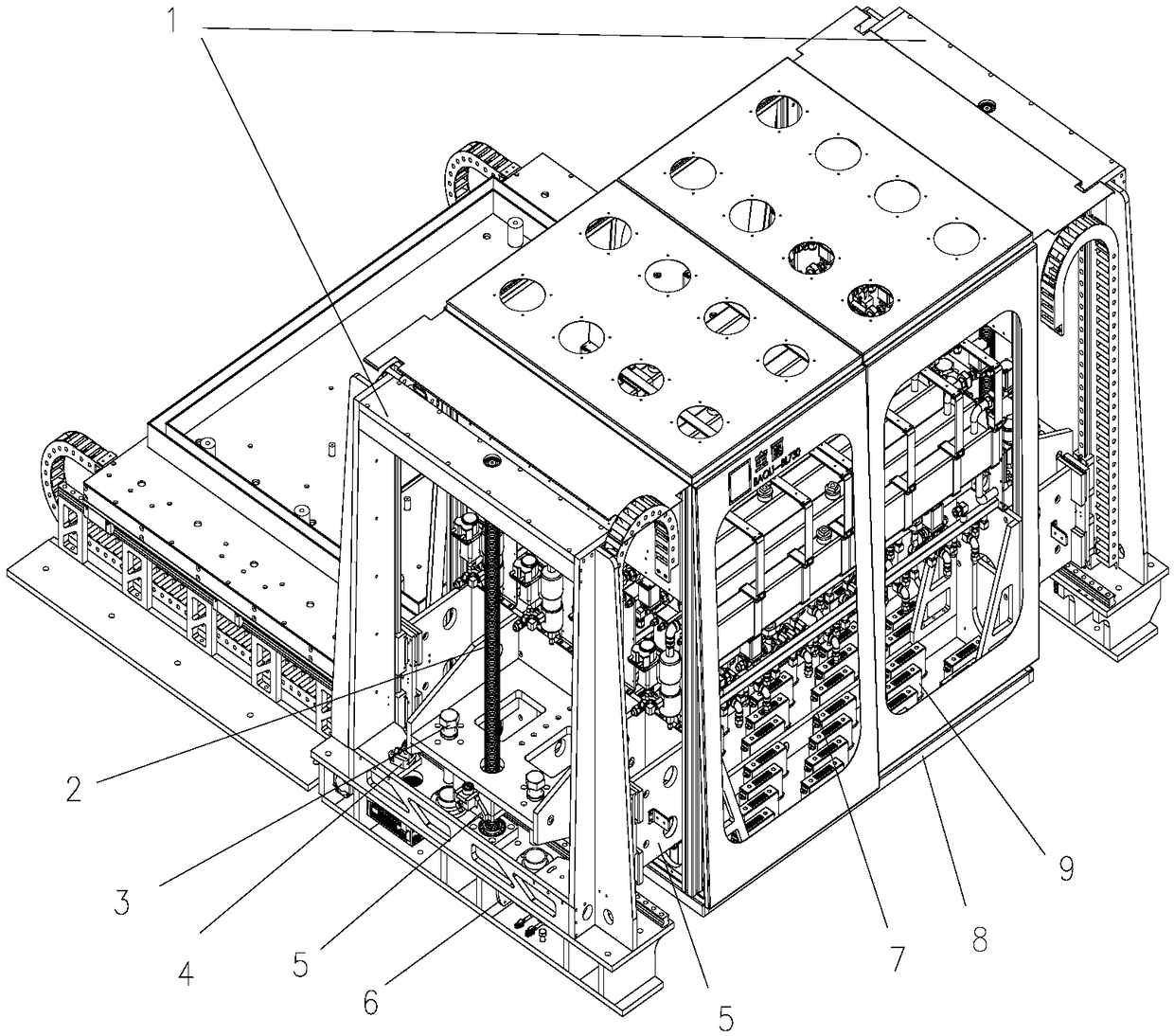

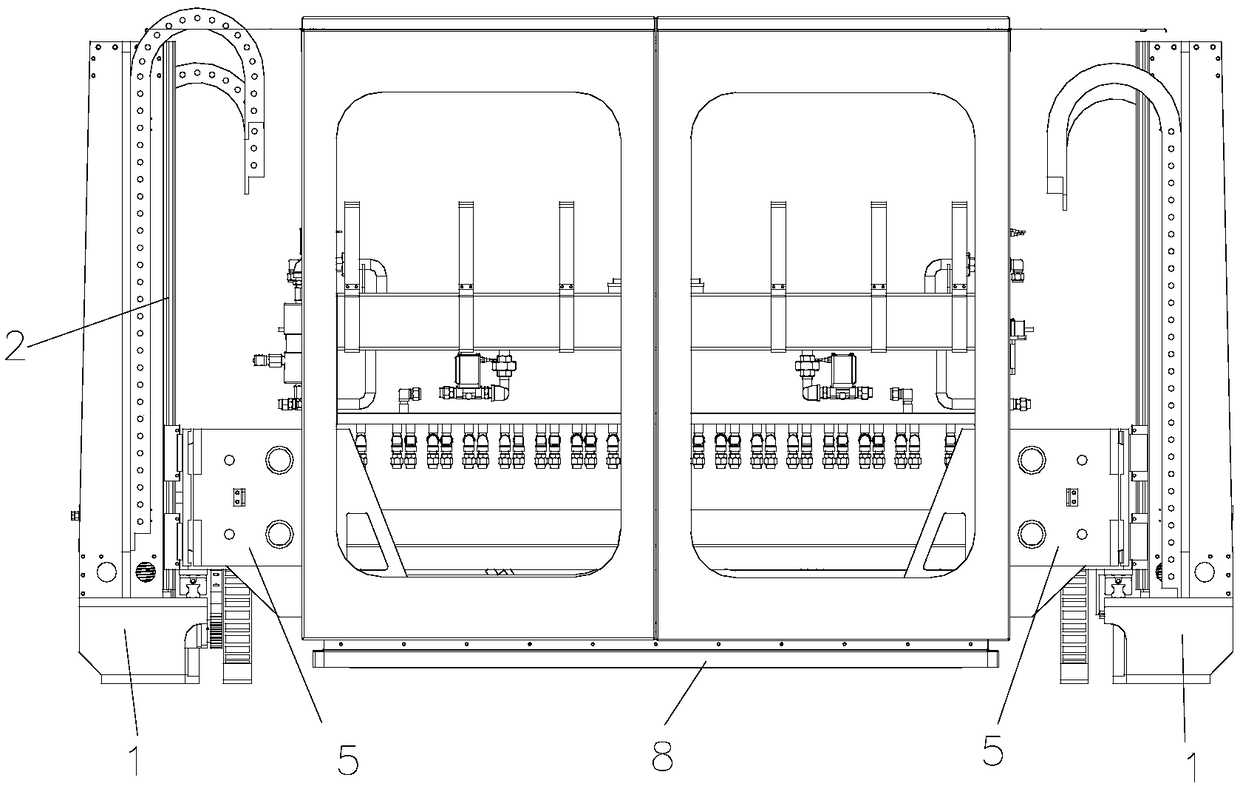

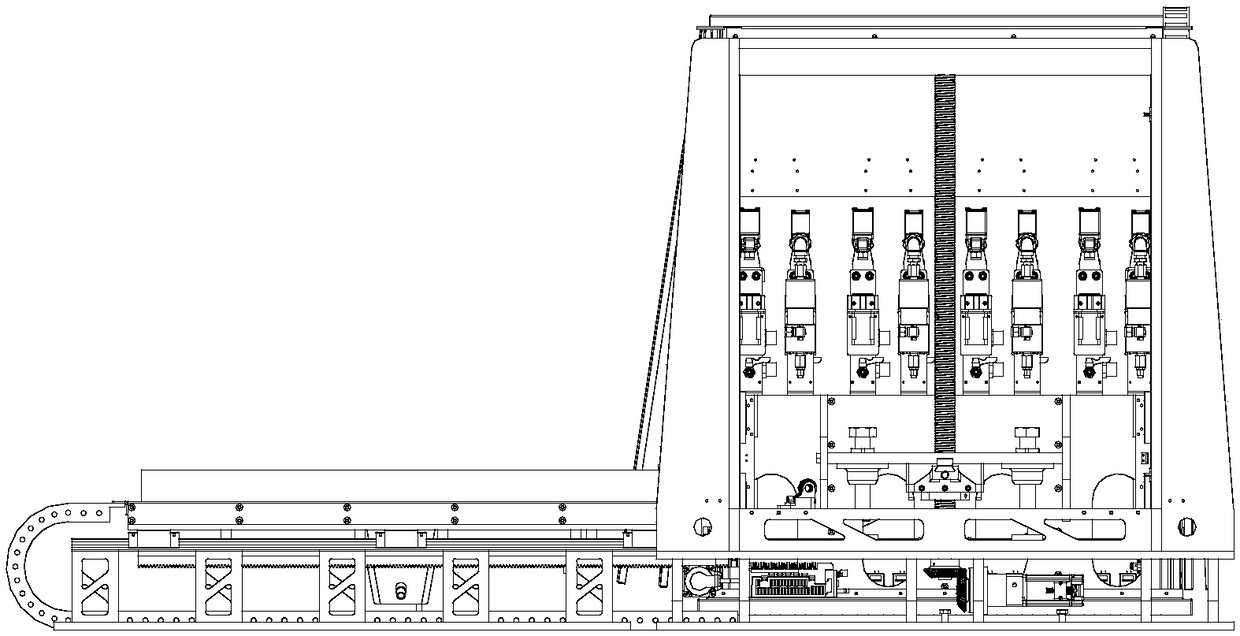

[0039] Figure 1-3 , a nozzle lifting and positioning method, the opposite sides of the mounting frame are installed on two lifting guide frames 1; the nozzle is installed on the mounting frame;

[0040] A ball screw 2 is set on the lifting guide frame;

[0041] Both the lifting guide frame and the ball screw are 2, and the 2 ball screws are respectively installed on the 2 lifting guide frames; the two ends of the mounting frame are set on the 2 ball screws; when the servo motor rotates, it can The transmission of the rod drives the installation frame and the nozzle to rise and fall;

[0042] The mounting frame is provided with an inclination sensor for detecting the inclination of the mounting frame;

[0043] The two ball screws are respectively driven by two independent servo motors 6;

[0044] The inclination sensor is connected to the MCU; the servo motor is controlled by the MCU;

[0045] The MCU controls the height of the installation frame and the nozzle by controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com