Clamping device of stator blade

A stator vane and clamping device technology, which is applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of small clamping end area of the stator vane and the inability to stably and reliably fix the stator vane, so as to achieve a clear design structure and reduce test costs , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

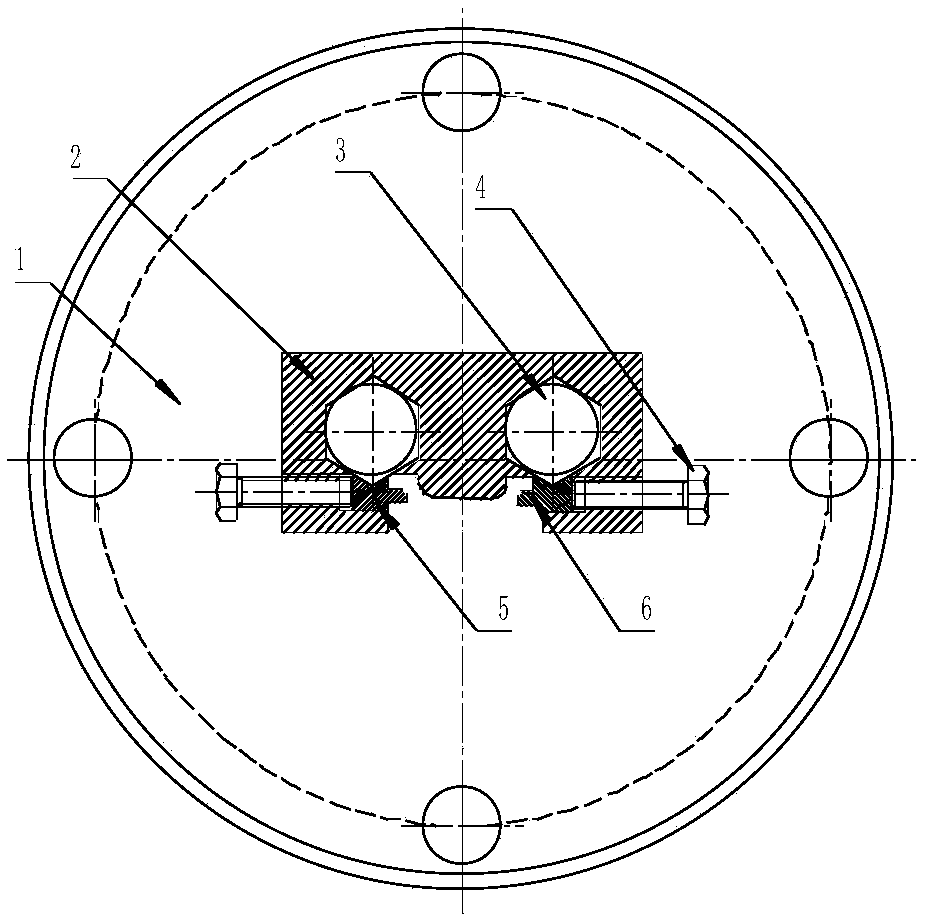

[0014] The present invention passes figure 1 The arc-shaped clamping device of the stator blade shown in the figure realizes stable and reliable installation when the clamping end area of the stator blade is small and arc-shaped.

[0015] The stator blade arc-shaped clamping device of the present invention includes a base 1, a fixed pressing block 2, a pressing bolt 3, an arc-shaped tightening bolt 4, a first arc-shaped tightening block 5, and a second arc-shaped tightening block 6; The base 1 is connected to the fixed pressing block 2 through the pressing bolt 3, the arc-shaped tightening bolt 4 is connected to the fixed pressing block 2 through threads, and the first arc-shaped pressing block 5 and the second arc-shaped pressing block 6 are connected through the arc-shaped Jacking bolt 4 is jacked up and fixed.

[0016] The hold-down bolts 3 are two M8×1 bolts, and the arc-shaped hold-down bolts 4 are four M4 bolts, which are installed and pressed from the side.

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com