Automatic metal surface processing device

An automatic processing, metal surface technology, applied in metal processing equipment, grinding devices, grinding/polishing safety devices, etc., can solve problems such as inability to identify, time-consuming and labor-intensive, and low processing efficiency, saving materials and ensuring imaging. Precision and accuracy, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

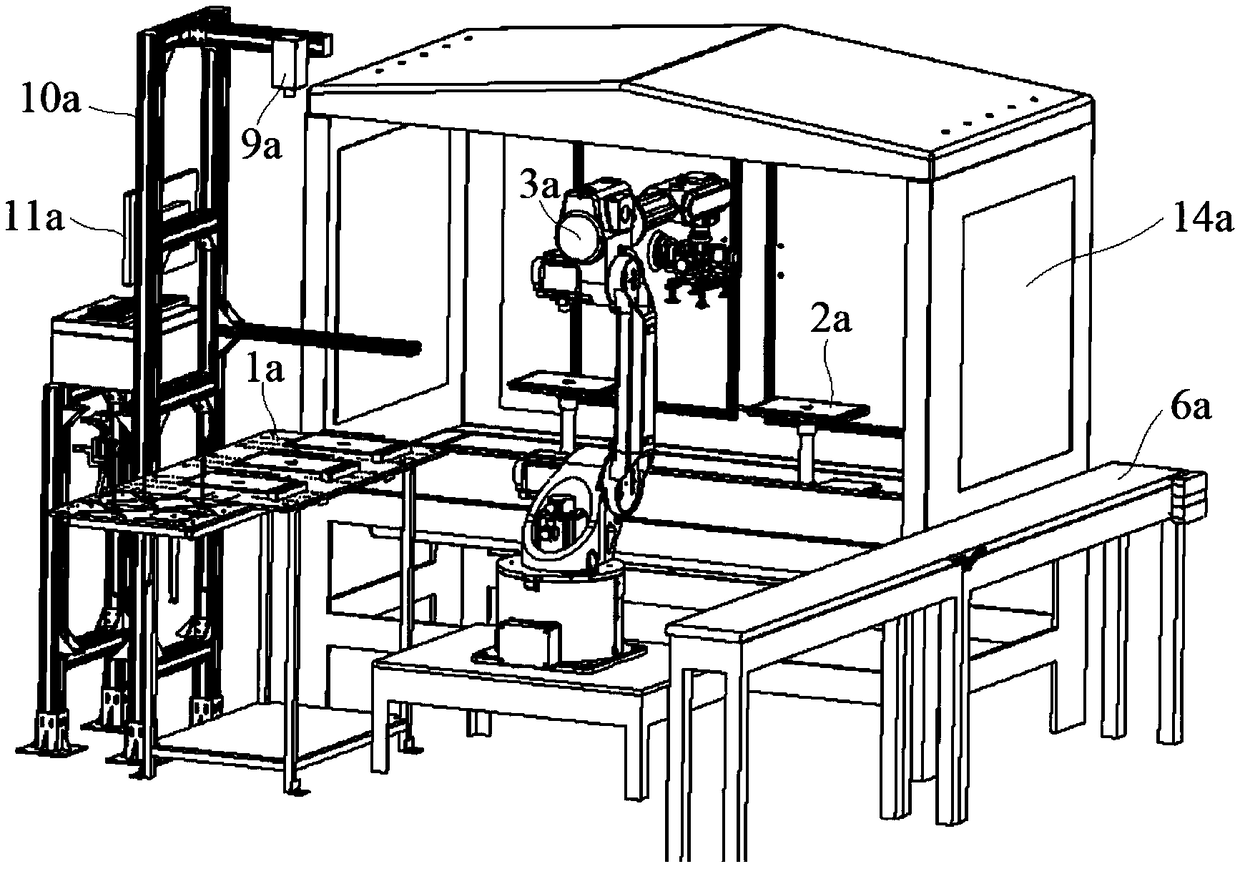

[0039] Embodiment 1: a kind of metal surface automatic processing device, comprises feeding support 1a, grinding support 2a, some mechanical arms 3a, grinding head 4a and material delivery clamp 5a, described grinding head 4a and material delivery clamp 5a are respectively connected with The end nodes of the mechanical arm 3a are installed and connected, and the feeding support 1a and the grinding support 2a are respectively arranged along the circumferential direction of the mechanical arm 3a;

[0040] Described loading support 1a comprises support 7a and the loading table 8a that is installed on the support 7a, and described loading table 8a has an imaging mechanism 9a on the side opposite to mechanical arm 3a, and this imaging mechanism 9a is installed on a The upper end of the mounting frame 10a is located above the loading table 8a, and the grinding support 2a includes a base 12a and several grinding tables 13a connected to the upper surface of the base 12a;

[0041] The ...

Embodiment 2

[0050] Embodiment 2: a kind of metal surface automatic processing device, comprises feeding support 1a, grinding support 2a, some mechanical arms 3a, grinding head 4a and material delivery clamp 5a, described grinding head 4a and material delivery clamp 5a are respectively connected with The end nodes of the mechanical arm 3a are installed and connected, and the feeding support 1a and the grinding support 2a are respectively arranged along the circumferential direction of the mechanical arm 3a;

[0051] Described loading support 1a comprises support 7a and the loading table 8a that is installed on the support 7a, and described loading table 8a has an imaging mechanism 9a on the side opposite to mechanical arm 3a, and this imaging mechanism 9a is installed on a The upper end of the mounting frame 10a is located above the loading table 8a, and the grinding support 2a includes a base 12a and several grinding tables 13a connected to the upper surface of the base 12a;

[0052] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com