Device and method for dynamic measurement of surface topography of high-temperature molten metal

A metal surface, dynamic measurement technology, used in measurement devices, optical devices, instruments, etc., can solve problems such as metal object shape defects, improve measurement stability, improve lighting brightness, and ensure measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

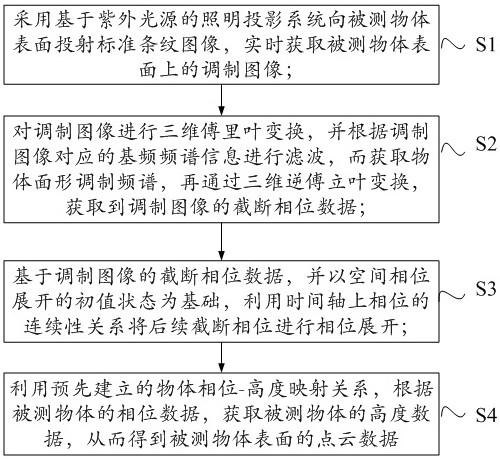

[0041] figure 1A method for dynamically measuring the surface topography of a high-temperature molten metal according to an exemplary embodiment of the present invention is shown, which includes the following steps:

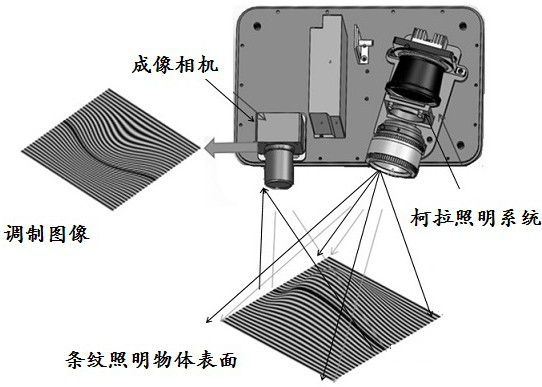

[0042] S1: Use the lighting projection system based on ultraviolet light source to project standard fringe images to the surface of the measured object, and obtain the modulated image on the surface of the measured object in real time;

[0043] S2: Perform three-dimensional Fourier transform on the modulated image, and perform filtering according to the fundamental frequency spectrum information corresponding to the modulated image to obtain the surface shape modulation spectrum of the object, and then obtain the modulated image through three-dimensional inverse Fourier transform truncated phase data of the image;

[0044] S3: Based on the truncated phase data of the modulated image, and based on the initial value state of the spatial phase unwrapping, use the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com