A loose separation device for food waste

A technology of food waste and separation equipment, which is applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc., which can solve the problems of food waste clogging the mesh, food waste liquid components are not easy to be separated, and the working efficiency of separation equipment is reduced. problem, to achieve the effect of improving the separation effect and increasing the liquid output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

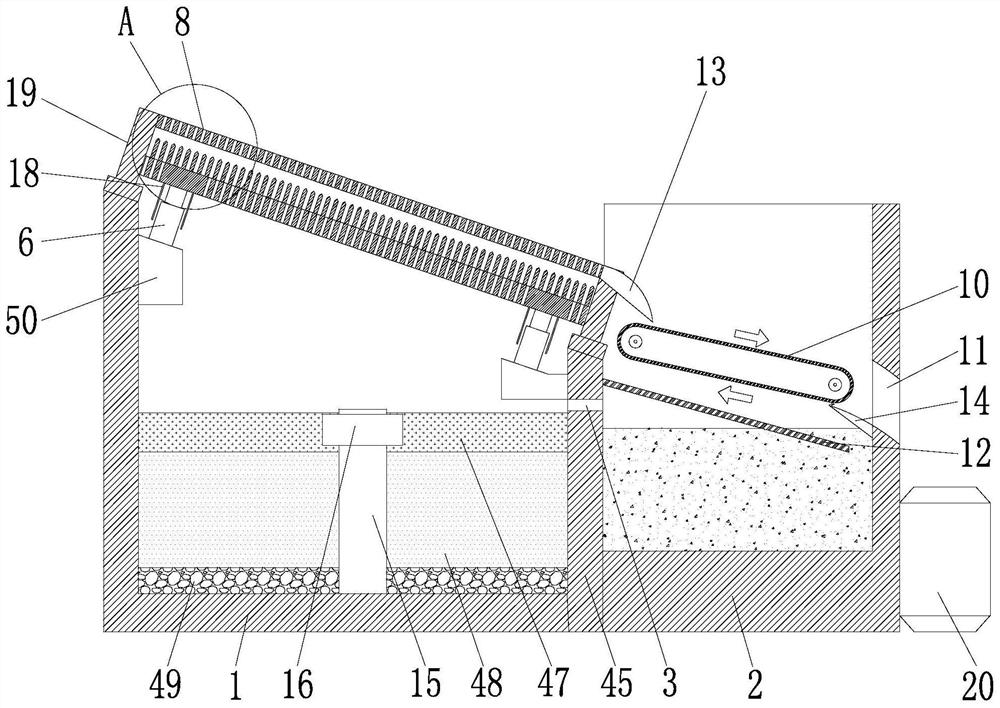

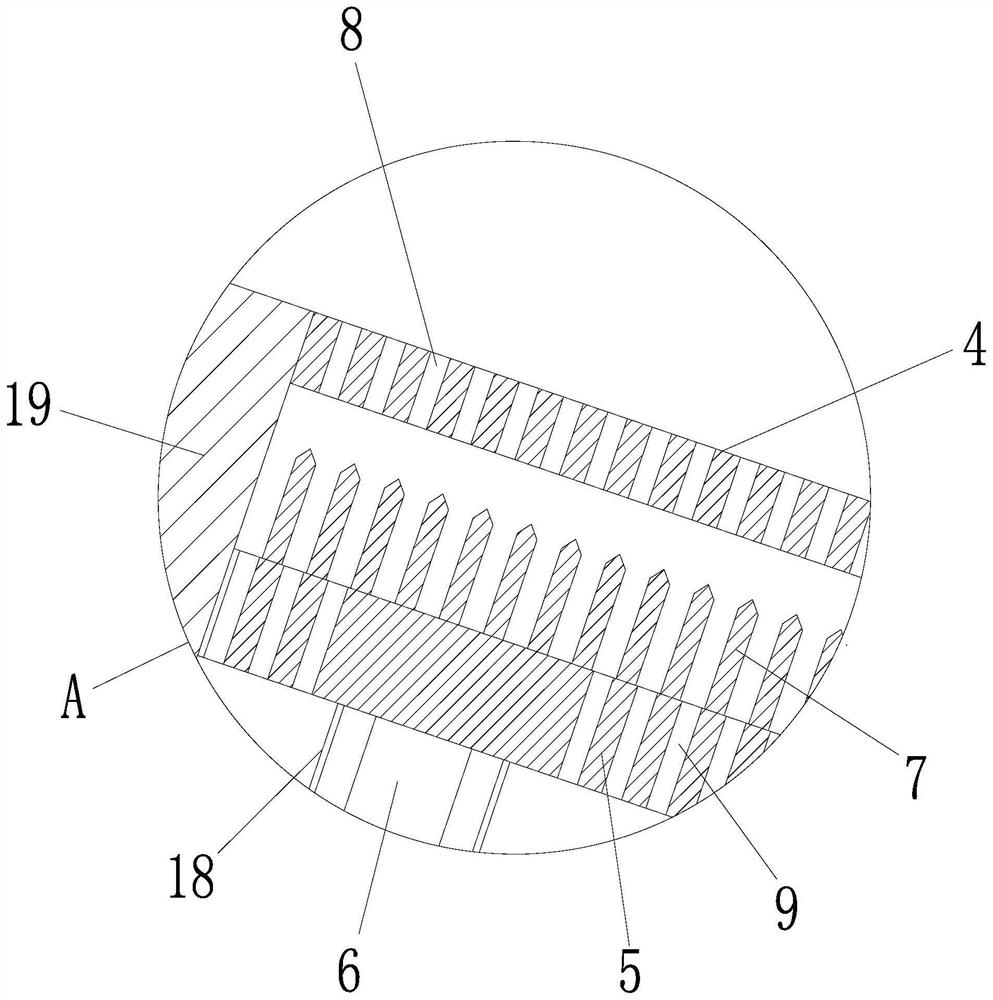

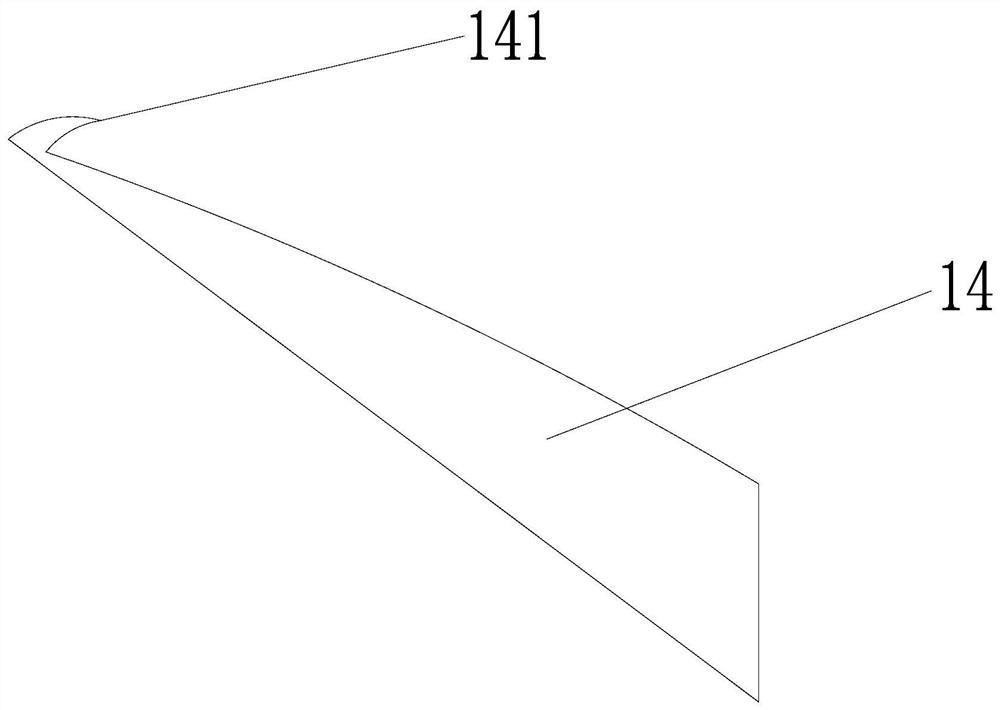

[0055] see figure 1 as well as figure 2 , the present embodiment provides a kind of food waste loose separation equipment, which may include a first separation box 1, a second separation box 2, a first solid-liquid separation device, a second solid-liquid separation device, a heating device and a solid collection Barrel 20.

[0056] The top of the first separation box 1 is opened, and the heights of opposite sides of the top are different. The first separation box 1 can store the liquid produced in the separation process of food waste, and a liquid outlet can be opened on the side wall of the first separation box 1, and a mud outlet can be opened at the bottom, so that the deposited silt and upper layer liquid can be separated. separate out. The first separation box 1 can be made of anti-corrosion material, and the inner wall can be coated with oil-proof paint, so as to facilitate the long-term use of the first separation box 1 .

[0057] The second separation box 2 is ar...

Embodiment 2

[0073] see Figure 4 , this embodiment provides a loose separation device for food waste, which adds a plurality of partitions 17 on the basis of Embodiment 1, wherein the second solid-liquid separation device further includes a plurality of partitions 17 . A plurality of partitions 17 are arranged below the filter plate 12, arranged in parallel and installed on the bottom wall of the second separation box 2, and arranged in a stepped manner. Moreover, the height of the partition 17 closest to the liquid inlet hole 3 is the largest, and the height of the partition 17 closest to the bottom of the filter plate 12 is the smallest.

[0074] In this embodiment, when the mixed liquid separated by the second solid-liquid separation device is stored in the second separation box 2, the storage liquid surrounded by the partition plate 17 near the bottom of the filter plate 12 and the second separation box 2 The space will be filled with liquid first, and then filled in sequence. At the...

Embodiment 3

[0076] please participate Figure 5 , Figure 6 as well as Figure 7 , This embodiment provides a loose separation device for food waste, which is similar to the separation device in Embodiment 1, the difference is that the separation device in this embodiment removes the heating device and adds an oil outlet mechanism.

[0077] Please combine Figure 8 , The oil outlet mechanism includes an oil outlet cylinder 31 , an oil outlet sleeve 32 , a mounting column 33 , a plurality of first elastic members 34 , and at least one second elastic member 35 . The top end of the oil outlet cylinder 31 is a closed end, and the bottom end is an open end and is fixed on the bottom wall of the first separation box 1 . A plurality of oil outlet holes 36 respectively corresponding to the plurality of elastic members 1 34 are defined on the side wall of the oil outlet cylinder 31 , and the free end of each elastic member 1 34 is blocked in the corresponding oil outlet hole 36 . A plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com