Multi-stage high-efficiency water purification equipment and method

A kind of water purification equipment and high-efficiency technology, applied in the direction of separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of inability to achieve fast and efficient filtration and purification of water, slow penetration speed, low filtration efficiency, etc., to achieve filtration High effect, fast purification and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

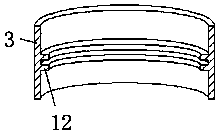

[0035] figure 1 It is a schematic diagram of the structure of the present invention. It can be seen from the accompanying drawings that the multi-stage high-efficiency water purification equipment includes several connected water purification buckets 3, each of which is equipped with a piston 4, and the center of the piston 4 is connected with a piston 4 rods 2, the top of the piston 4 rod 2 is provided with a hydraulic press 1, the hydraulic press 1 controls the telescopic movement of the piston 4 rod 2, and the clean water bucket 3 is provided with one or more filter devices near its bottom, so The clean water bucket 3 is provided with a water inlet and a water outlet, the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com