Technical method for installing steam turbine generator stator slot wedge by hydraulic power

A turbo-generator and hydraulic power technology, which is applied in the manufacture of electric generators, stator/rotor bodies, electrical components, etc., can solve hidden dangers, the impact force is greatly affected by human factors, and the hand hammer hits the generator stator Quality and other issues, to achieve the effect of eliminating hammer damage, eliminating quality risks, and reducing quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

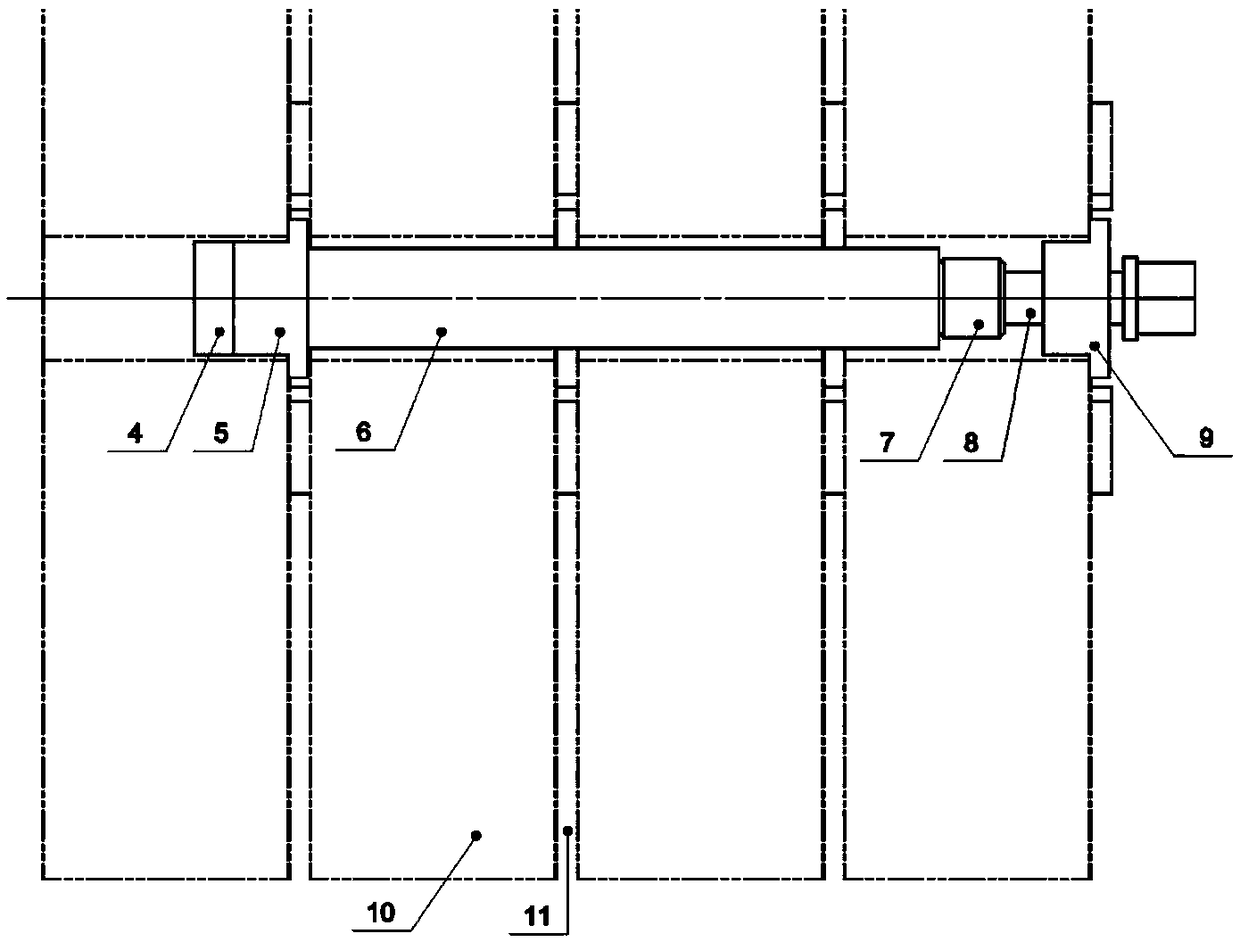

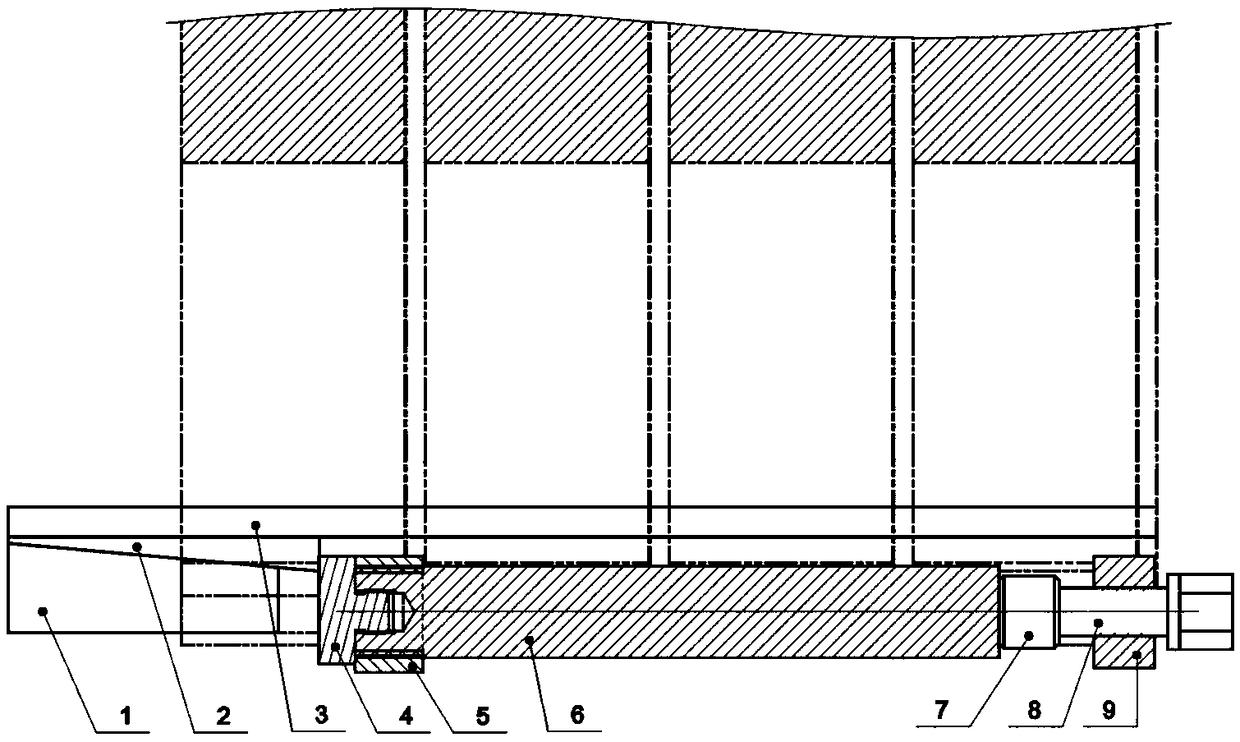

[0023] Such as figure 1 Shown, the process method of using hydraulic power to install the stator slot wedge of a large steam turbine generator

[0024] 1) This installation method is aimed at the structure with the opposite diagonal wedge 2 under the stator slot wedge 1;

[0025] 2) Preparations before assembly of stator slot wedge 1: After installing the spacer 3 under the stator slot wedge 1 in place as required, place the stator slot wedge 1 at the predetermined installation position of the stator core 10, and the stator slot wedge 1 is used for fixing The inclined wedge 2 is inserted under the slot wedge 1 manually, and the distance from the actual required installation position is between 10 and 15 mm. This distance is used as the tightening stroke of the hydraulic jack 6;

[0026] 3) Such as figure 2 As shown, screw the end thread of the hydraulic jack 6 into the fixed block 5, screw the wedge 2 to the top block 4 on the internal thread of the hydraulic jack 6 pillar, and cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com