Spliced stator structure with extremely-low cogging torque

A technology of cogging torque and stator structure, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc. Magnetic performance, simple assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

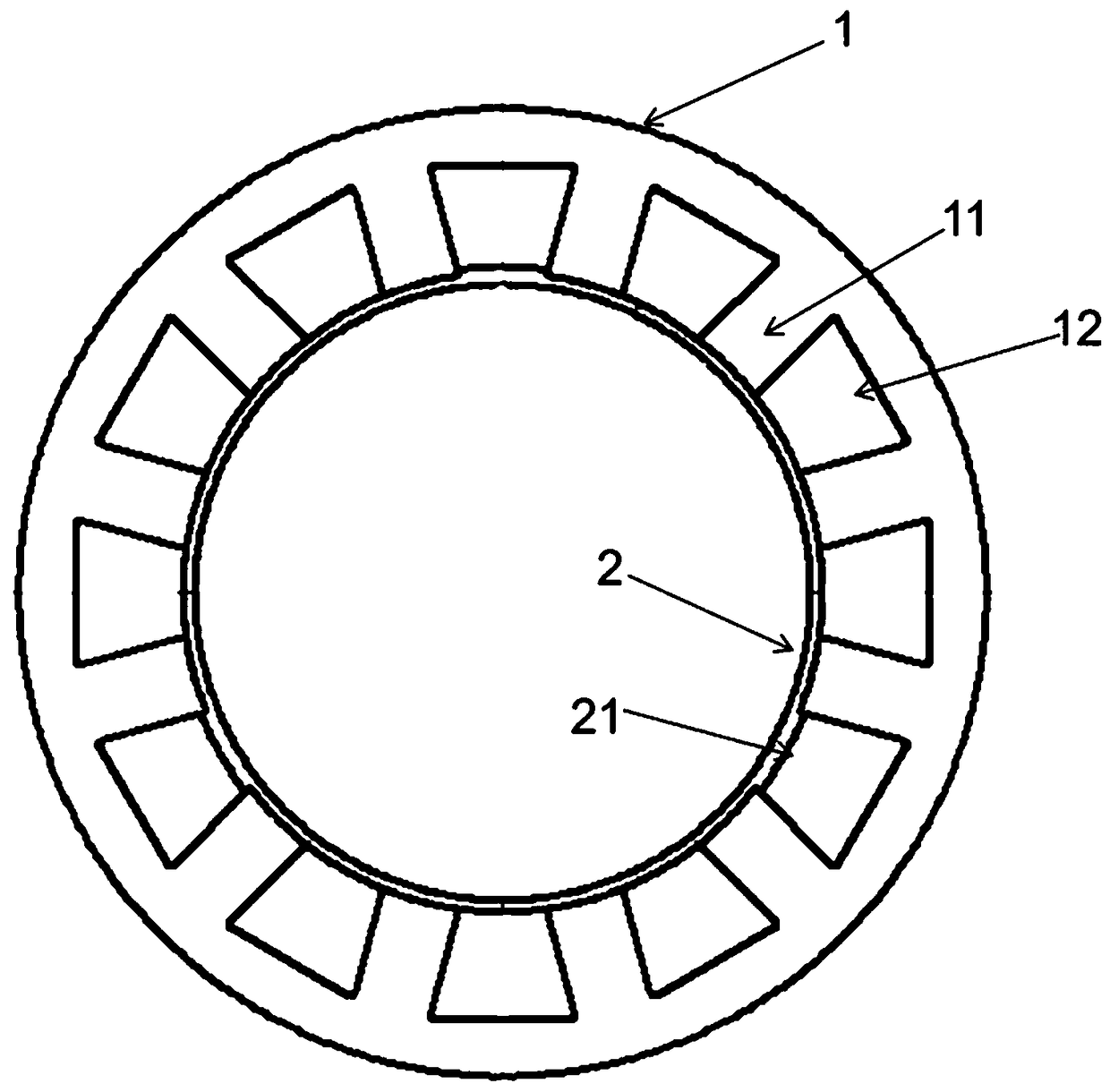

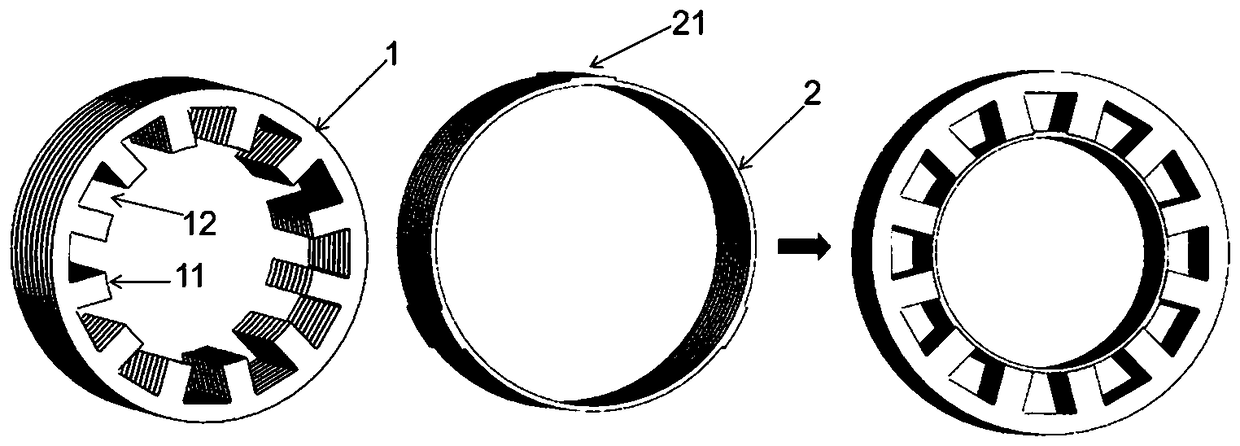

[0024] Such as figure 1 and figure 2 As shown, a stator structure with extremely low cogging torque provided by the present invention includes: a stator outer part 1 of an annular structure and a stator inner part 2 of an annular structure; the inner surface of the stator outer part 1 is circumferentially spaced A plurality of internal teeth 11 are provided; stator notches 12 are formed between adjacent internal teeth 11; closed. The outer surface of the stator outer part 1 is provided with a plurality of protruding parts 21 inserted into the stator slots 12 at intervals along the circumferential direction to prevent the stator outer part 1 and the stator inner part 2 from sliding.

[0025] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com