Thermal-link temperature intelligent detection system and detection method thereof based on Internet of Things

A thermal fuse and intelligent detection technology, applied in temperature control, control/regulation system, non-electric variable control, etc., can solve the problem of remote monitoring of the Internet of Things platform without realizing the underlying work of the single-chip microcomputer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

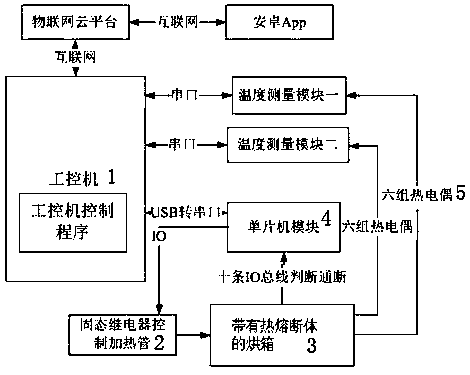

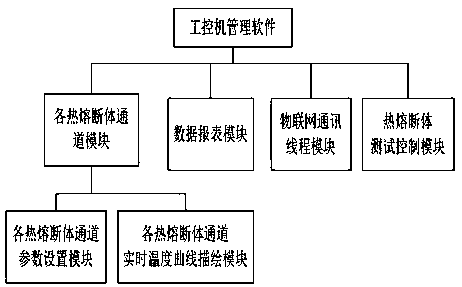

[0031] Such as figure 1 Shown is the first embodiment of the thermal fuse temperature intelligent detection system based on the Internet of Things of the present invention, including an industrial computer 1, an oven 3, a single-chip module 4 and observation equipment, the industrial computer 1 and the observation equipment are connected through the Internet of Things, and the industrial computer 1 is electrically connected with the single-chip microcomputer module 4. The oven 3 is provided with a mounting plate for installing a thermal fuse, a heating pipe 2 and a temperature measurement module. There are several thermal fuses on the mounting plate, and each thermal fuse is equipped with an independent detection circuit, the single-chip microcomputer module 4 is electrically connected to the heating pipe 2, and the temperature measurement module is electrically connected to the industrial computer 1. In this embodiment, the single-chip module 4 uses a STC15W4k56S4 single-chip...

Embodiment 2

[0044] This embodiment is similar to Embodiment 1, the difference is that in this embodiment, an oil tanker is used for heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com