Engineering machinery test bench

A technology of construction machinery and test bench, which is applied in the field of construction machinery, can solve the problems of inability to detect loads and affect the safety and stability of construction machinery, and achieve the effect of strong controllability and easy research and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

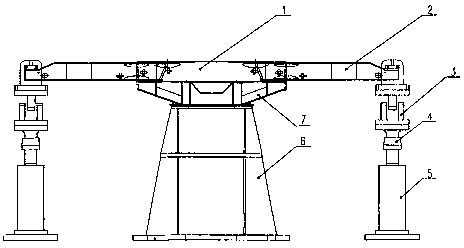

[0016] Embodiment 1: Test when simulating three-leg support

[0017] During the lifting operation of construction machinery, there may be a state supported by three outriggers, that is, one of the vertical outriggers is not stressed or called suspended. At this time, the supporting reaction force of the other three vertical outriggers or Through theoretical calculation, the support reaction force of the other three vertical legs is obtained.

[0018] During the test, first assemble the tested engineering machinery vehicle frame 1 and support 2, hydraulic drive 5, force detection device 4 and related test tooling according to the content of the present invention. On the test bench, the corresponding load applied to the vertical leg is simulated by the hydraulic driver 5 to test the parameters such as strain and displacement at the relevant positions of the construction machine frame 1 and the bracket 2 .

Embodiment 2

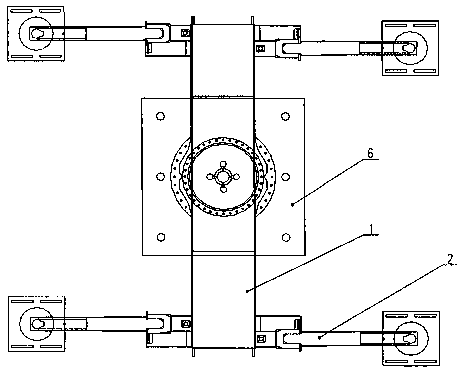

[0019] Embodiment 2: Simulation test and fatigue test when simulating the rotation of the suspended heavy object

[0020] During the lifting operation of construction machinery, the rotation of the heavy object is a common working condition. The change of the support reaction force on the outriggers is reflected in the change of the support reaction force on the four outriggers with the position of the heavy object. keep changing. At this time, the change of the support reaction force of the four vertical legs can be obtained through actual measurement of the support reaction force of the four vertical legs or through theoretical calculation.

[0021] During the test, first assemble the tested engineering machinery vehicle frame 1 and support 2, hydraulic drive 5, force detection device 4 and related test tooling according to the content of the present invention. On the test bench, the hydraulic driver 5 is used to simulate the corresponding dynamic change load applied to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com