System for working by means of hydrogen energy of metal hydride

A hydride and metal technology, applied in ocean energy power generation, steam engine installations, machines/engines, etc., can solve the problems of low system energy conversion rate, small generator power generation, limited promotion value, etc., and achieve an economical energy saving and emission reduction. Benefit, create economic benefits, expand the effect of application scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

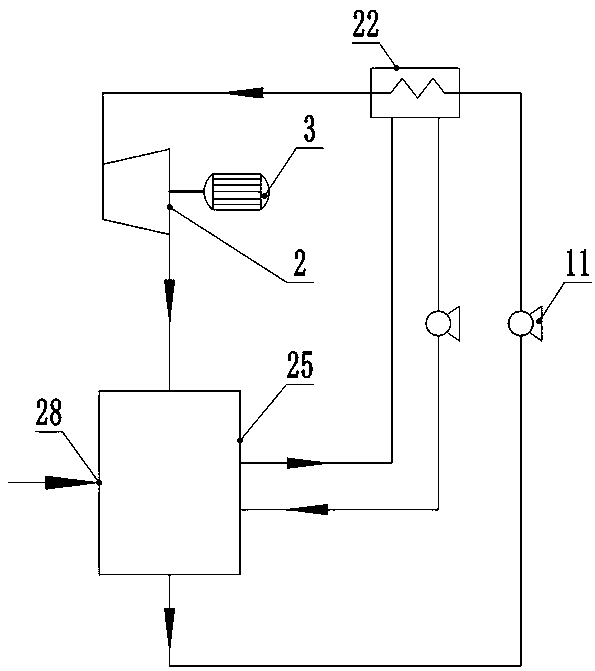

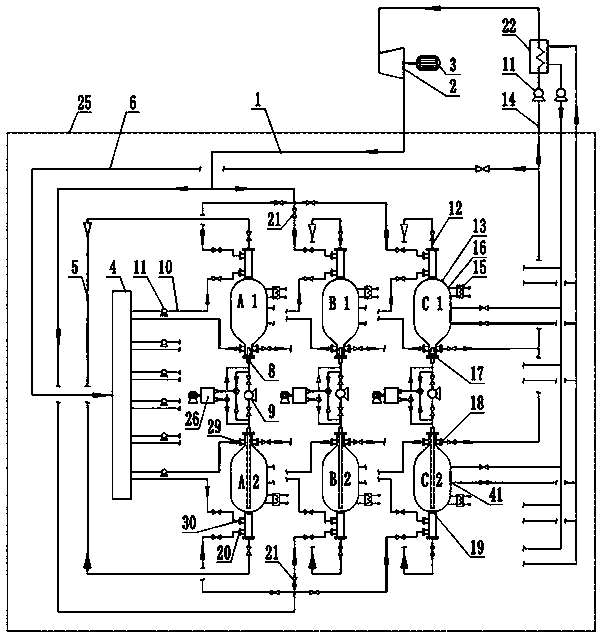

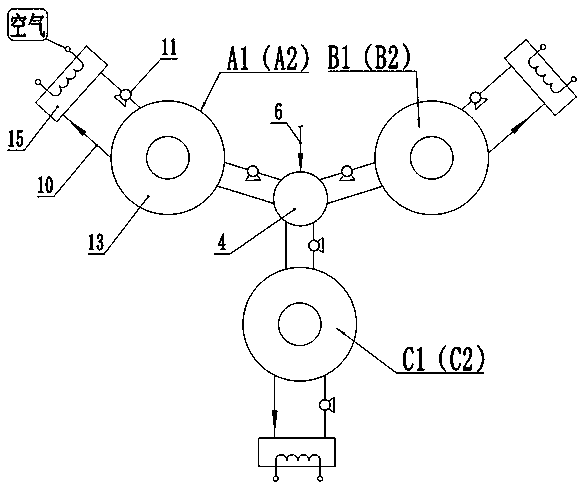

[0024] Metal hydride hydrogen energy work system of the present invention such as Figure 1-Figure 3As shown, it includes an expander 2, a generator 3, a hydrogen heat exchange center 4, an air energy heat exchanger 15 and three sets of hydrogen reaction bed groups 13, and each hydrogen reaction bed group contains two hydrogen reaction beds. The expander 2 is connected to the generator 3 shafts, and the electricity generated by the generator is incorporated into the grid for external supply. The hydrogen reaction bed is provided with a hydrogen inlet 20 , a hydrogen outlet 18 , a hydrogen return outlet 12 , a metal addition outlet 17 , a circulating hydrogen outlet 29 , a circulating hydrogen inlet 30 , a circulating heat exchange port 41 and a heat exchange hydrogen port 16 . The hydrogen return port 12 is provided with a filter screen 19, and the metal addition outlet 17 is inserted into the filling gun 8. The length of the filling gun 8 can be adjusted according to the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com