Floor drain housing and floor drain provided with floor drain housing

A floor drain and shell technology, which is applied to water supply devices, waterway systems, drainage structures, etc., can solve the problems of difficult maintenance, unused usage by installers, leakage of connecting ports, etc., and achieve the effect of preventing leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Eight specific embodiments of the present invention and specific embodiments of the effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

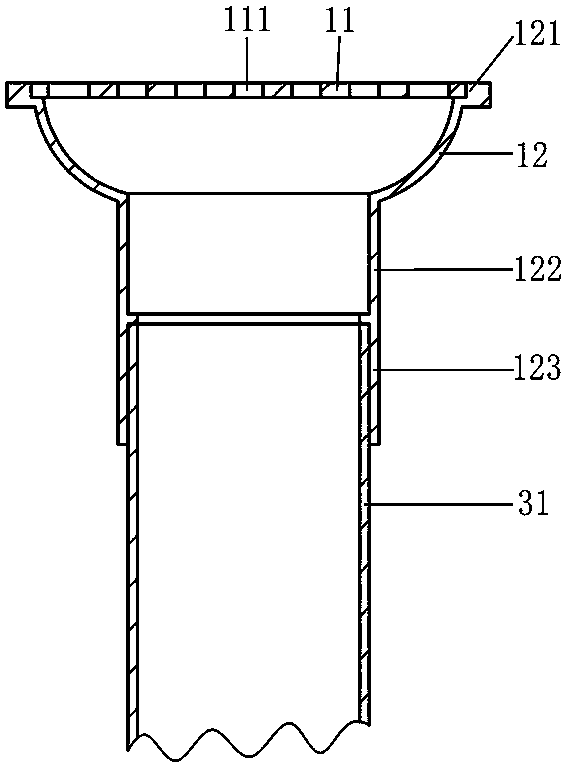

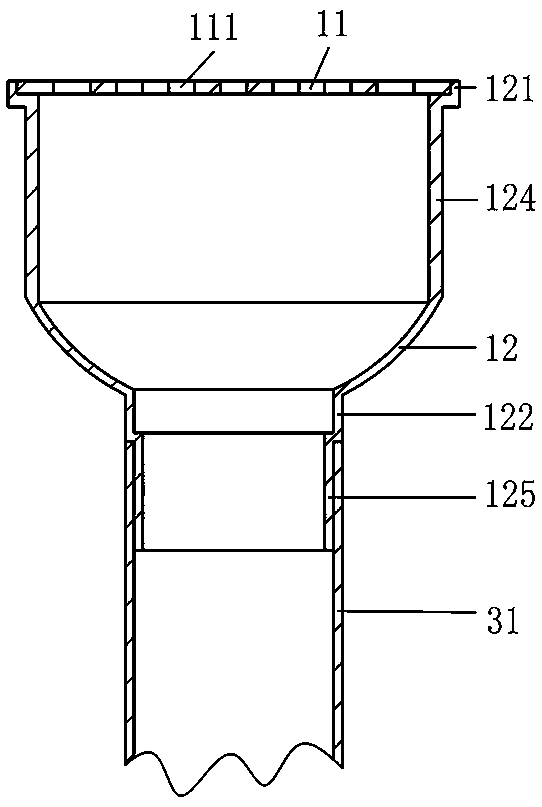

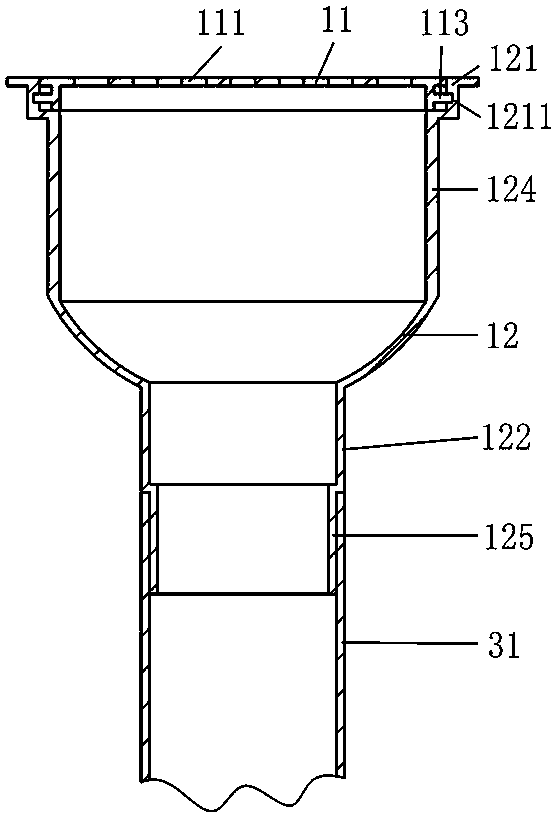

[0039] attached figure 1 What is shown is a structural schematic view of the first embodiment of the floor drain housing of the present invention.

[0040] Such as figure 1 As shown, the floor drain housing is composed of a floor drain grate 11 and a floor drain housing main body 12. The surface of the floor drain grate 11 has drainage holes 111. The floor drain housing main body 12 consists of an upward largest socket end 121 and an upward minimum The socket end 122 and a downward socket end 123 are connected by integral injection molding in the upper and lower order. According to the national floor drain standard GB / T27710-2011, the wall thickness of the downward socket end 123 of the main body 12 of the floor drain shell, The inner diameter of the pipe and the depth of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com