Medical drug material conveying U-shaped screw shaft closed transmission system

A transmission system and screw shaft technology, applied in the field of transmission system of medical and pharmaceutical material conveying equipment, can solve the problems of easy wear, long consumption time, high cost, no change in pitch, convenient maintenance and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

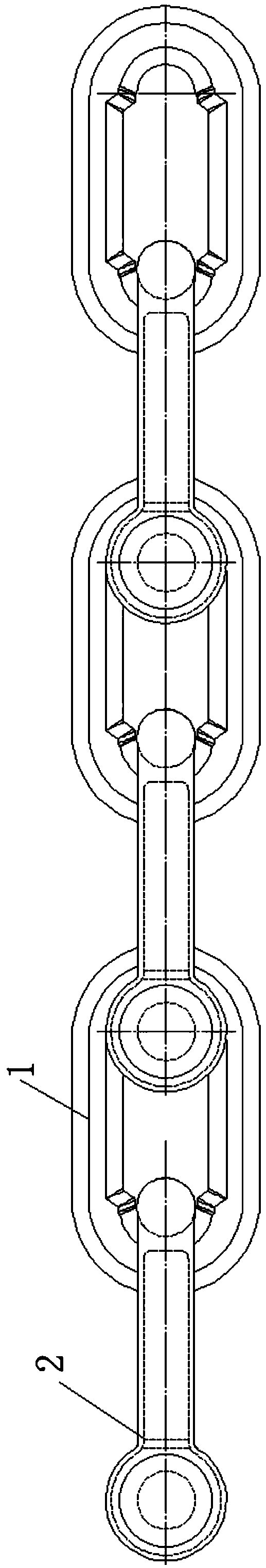

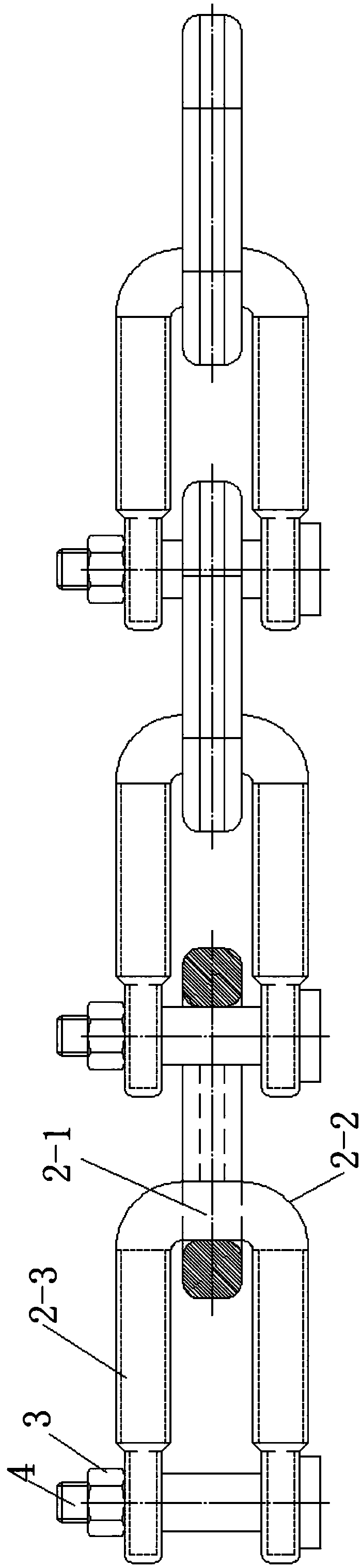

[0018] in figure 1 , figure 2 Among them, the U-shaped screw shaft closed transmission system for medical drug material transportation of the present invention is composed of a sleeve arc closed vertical chain ring 1 with a sleeve arc surface and a U-shaped screw shaft closed flat chain ring with a cylindrical transmission contact surface; The U-shaped screw shaft closed flat chain ring and the sleeve arc closed vertical chain ring are alternately connected to each other, and then the head and tail are connected again to form a closed chain; the U-shaped screw shaft closed flat chain ring includes a U with a connecting hole The U-shaped flat chain ring 2 is installed in the connecting hole of the U-shaped flat chain ring through the fastening nut 3, and the screw shaft 4 with a cylindrical transmission surface; the U-shaped screw shaft closes the cylindrical surface and sleeve arc of the flat chain ring The arc surface of the closed vertical chain ring has the same reference c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com