Automatic bagged printing ink extruder

A technology of extruder and ink, which is applied in the direction of packaging, transportation and packaging, and unsealing of packaged objects, which can solve the problems of high packaging cost, waste, and heavy weight, and achieve the effects of easy recycling, reduced ink residue, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

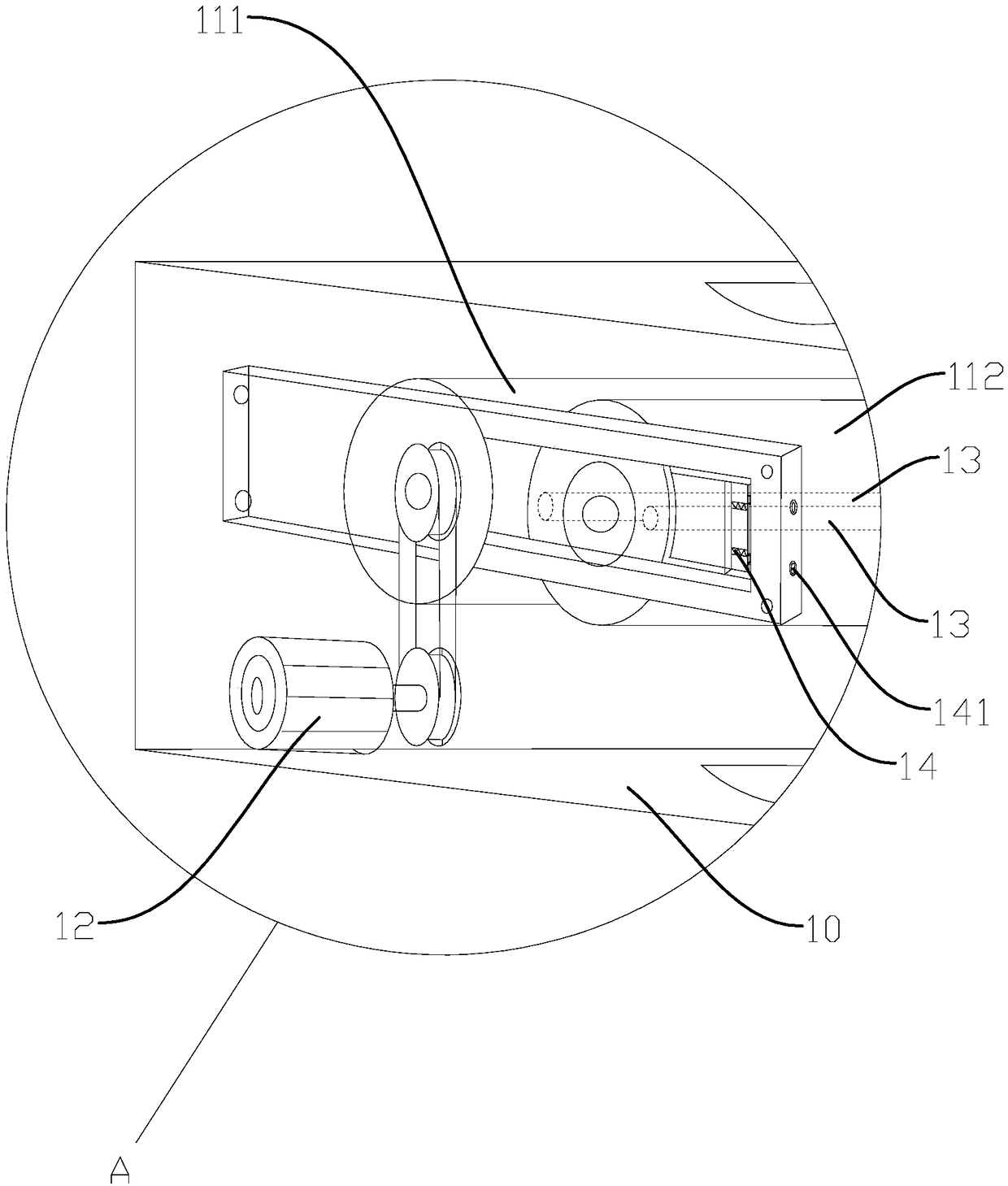

[0022] refer to figure 1 with figure 2 , a bagged ink automatic extruder, comprising: a base 10; a nip roller assembly, including a first nip roller 111 and a second nip roller 112 that are rotatably arranged on the base 10, the first nip roller 111 and the second pinch roller 112 can clamp the ink bag 31; the driving device 12 is arranged on the base 10 and is used to drive the first pinch roller 111 and / or the second pinch roller 112 to rotate so that the pinch roller assembly can move along the ink The bag 31 moves to squeeze the ink out of the ink bag 31 . In the present invention, the first nip roller 111 and the second nip roller 112 can clamp the ink bag 31, and can rotate under the drive of the driving device 12 to move along the ink bag 31, thus the ink can be squeezed out quickly and fully , can adapt to the production requirements of corresponding equipment, and can effectively reduce ink residue and waste, and is also convenient for the recycling of the ink bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com