Ship stern machining platform and adjusting method

A technology for processing a platform and a stern, which is applied to the processing platform and adjustment field of the stern of a ship, can solve the problems of not being applicable to the stern of the ship, the scope of application is small, the clamping mechanism cannot be adjusted, etc., and achieves high practicability, wide application, Flexible structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

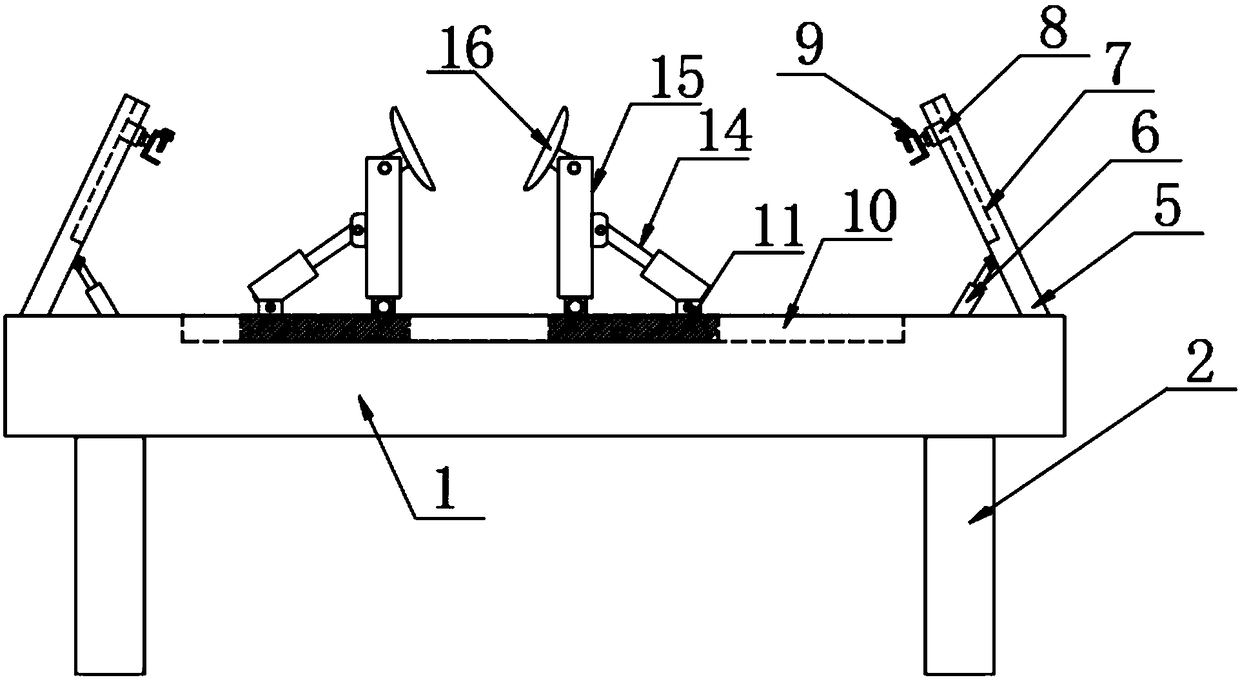

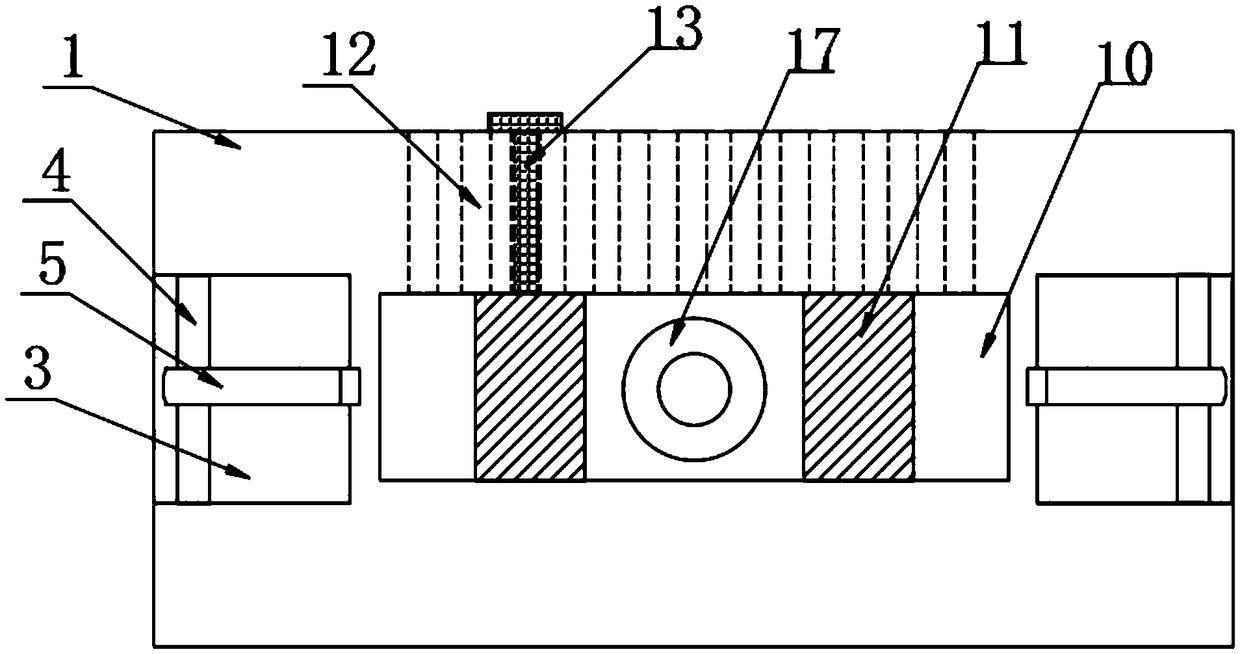

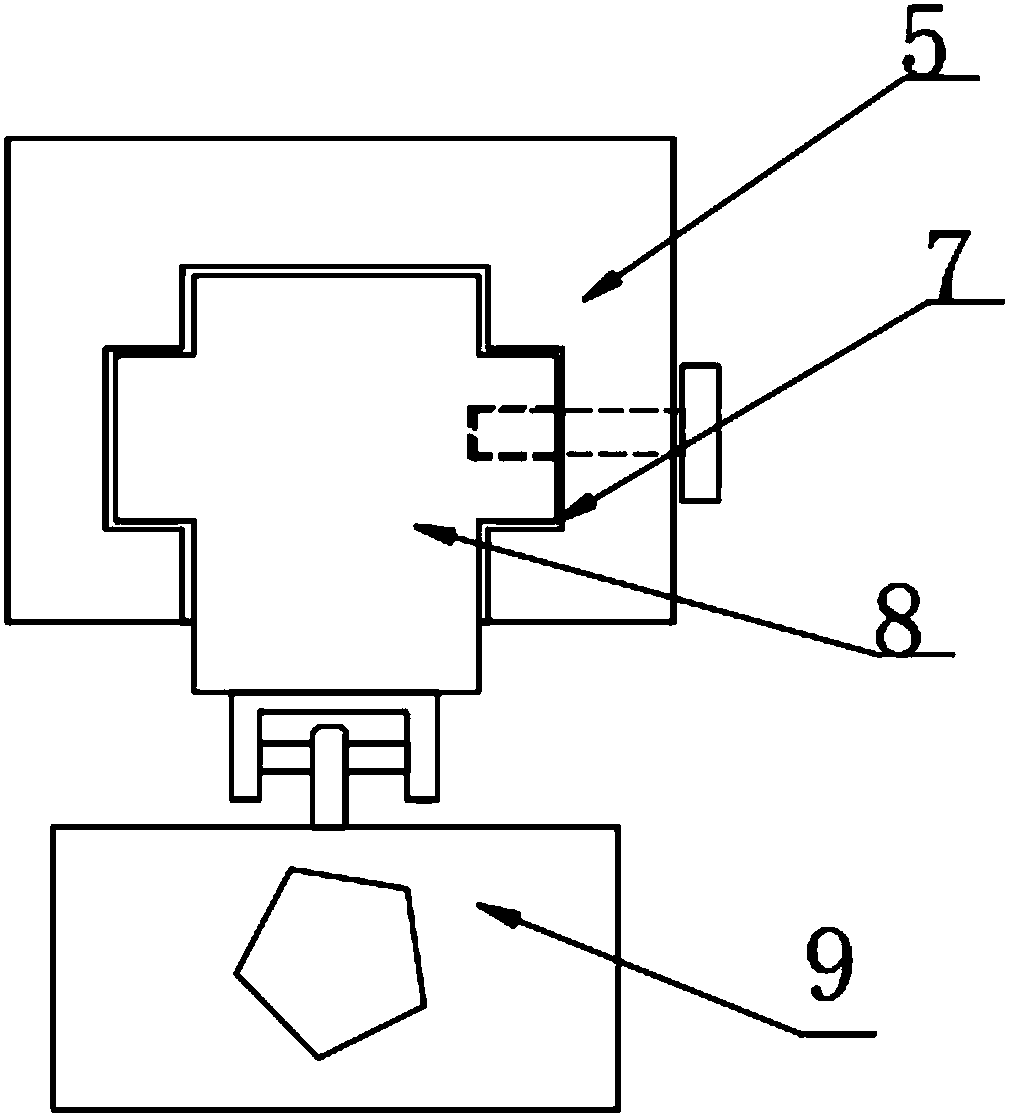

[0024] The present invention provides such as Figure 1-3 The ship stern processing platform shown includes a workbench 1. The four corners of the bottom outer wall of the workbench 1 are fixed with support legs 2 by screws. The notches of each groove 3 are connected with a rotating rod 4 in rotation, and the two grooves 3 are respectively connected with an adjustment support plate 5 through the rotating rod 4, and the inside of the groove 3 is hinged with a first hydraulic cylinder 6 arranged obliquely. The output end of the first hydraulic cylinder 6 is hinged to the bottom end of one side of the outer wall of the adjustment support plate 5, and the outer walls of the opposite side of the two adjustment support plates 5 are provided with a chute 7, and the inner wall of the chute 7 is slidably connected with a slider 8 , the slider 8 is located at the outer wall of the outer section of the adjustment support plate 5 and is hinged with a fixed splint 9, and the middle of the ...

Embodiment 2

[0034] A method for adjusting a ship stern processing platform, including the ship stern processing platform, further comprising the following steps:

[0035] S1: the second hydraulic cylinder 14 is set, the supporting plate 15 and the movable plate 11 are hinged;

[0036] S2: The supporting plate 15 can change the angle between it and the movable plate 11 under the push of the piston rod of the second hydraulic cylinder 14, and then adjust the angle between the two supporting plates 15;

[0037]S3: Support the stern side wall cylinders of different sizes through the rubber pad 16, and at the same time adjust the angle between the adjustment plate 5 and the workbench 1 by starting the first hydraulic cylinder 6;

[0038] S4: adjust the position of the fixed splint 9 by sliding the slider 8 on the inner wall of the chute 7, so that the clamping height of the fixed splint 9 can be adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com