Self-regulation pressing point type rotary clamping device with in-place detection function

A technology of self-adjusting and rotating clamps, which is applied in the direction of chucks, manufacturing tools, fluid pressure actuating devices, etc., can solve the problems of high manufacturing and maintenance costs, time-consuming and laborious installation and debugging, and large power loss, so as to save manufacturing costs, The effect of saving power loss and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

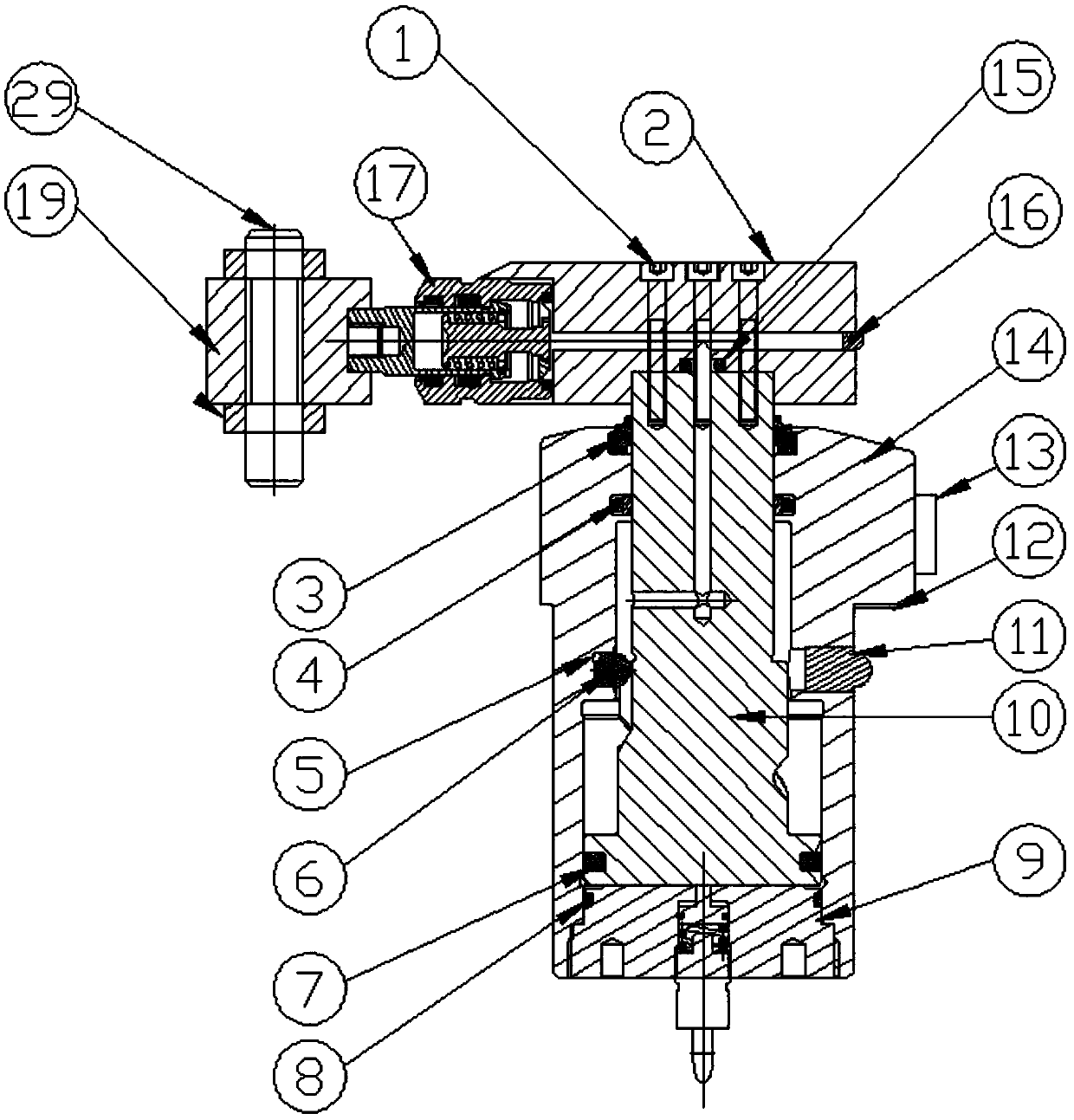

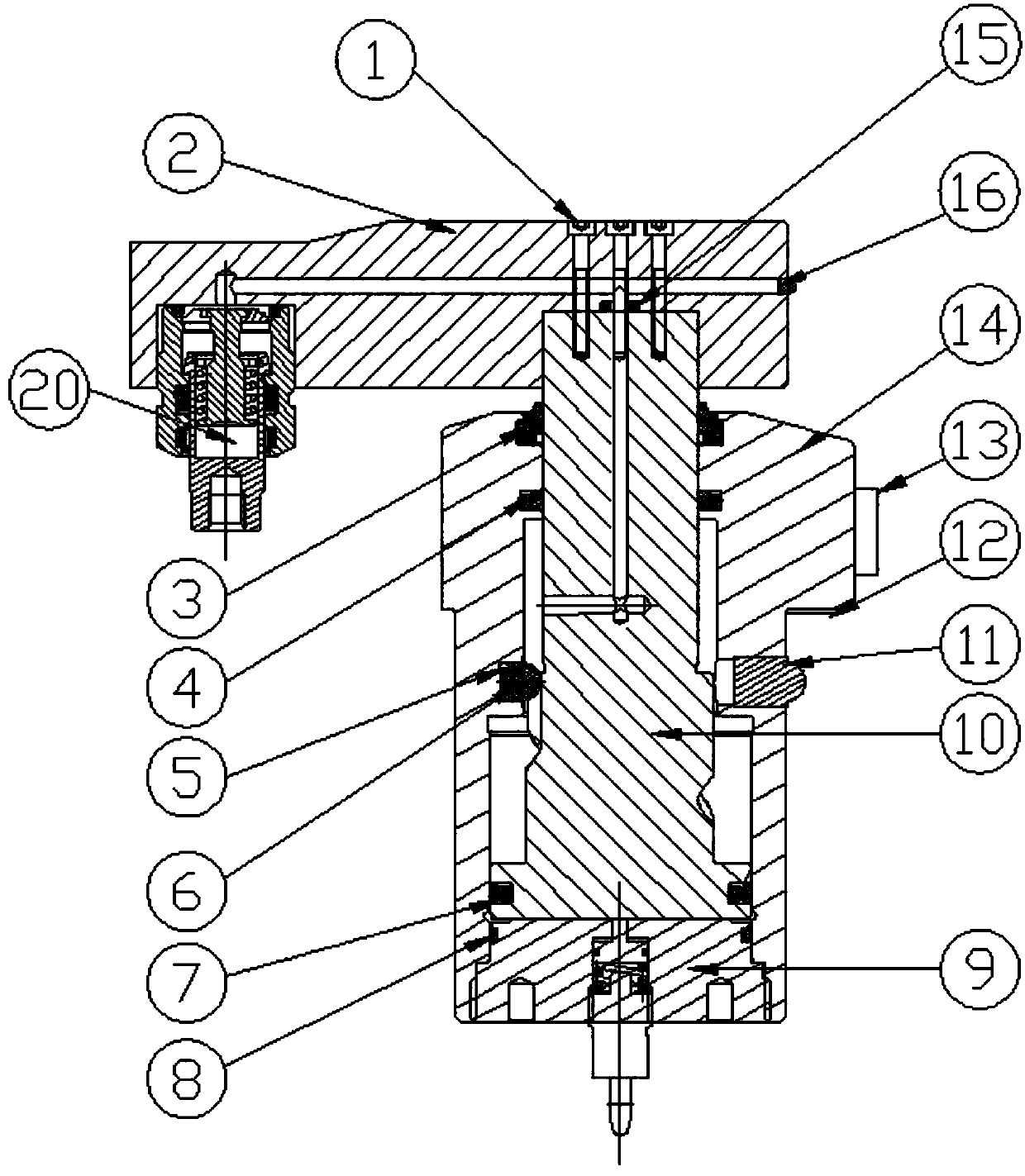

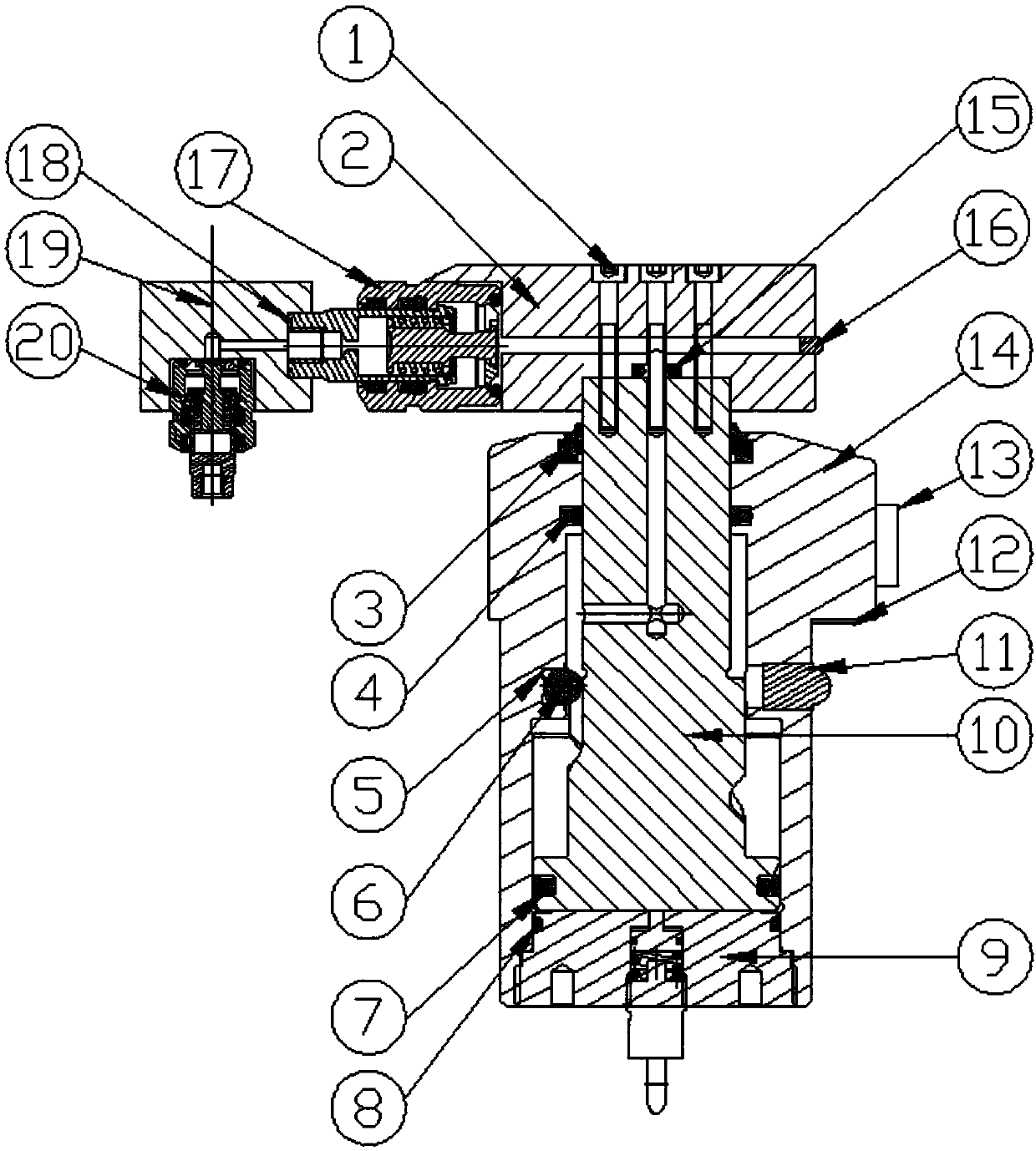

[0022] Attached below Figure 1-5 The present invention is described further:

[0023] The self-adjusting pressing point type rotary clamp with in-position detection function includes a cylinder body 14, which is provided with a connected upper inner cavity and a lower inner cavity, and the piston 10 is in sliding and sealed connection with the upper inner cavity and the lower inner cavity , the big end of the piston 10 is located in the lower inner cavity, and the lower inner cavity above the big end is filled with hydraulic oil, the bottom of the big end is connected to the oil circuit one, and the bottom of the cylinder body 14 is sealed by the end cover 9, and the connection between the piston 10 and the cylinder body 14 There is a rotating mechanism between them, the top of the piston 10 protrudes from the top of the cylinder body 14 and is fixedly connected with the telescopic pressing arm 2, and the upper inner cavity and the lower inner cavity are equipped with in-posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com