Powerless Swivel Clamp

A technology of power rotation and clamp, applied in the field of clamp components, can solve problems such as pressure change, leakage, instability, etc., and achieve the effects of stable temperature change control, energy saving and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

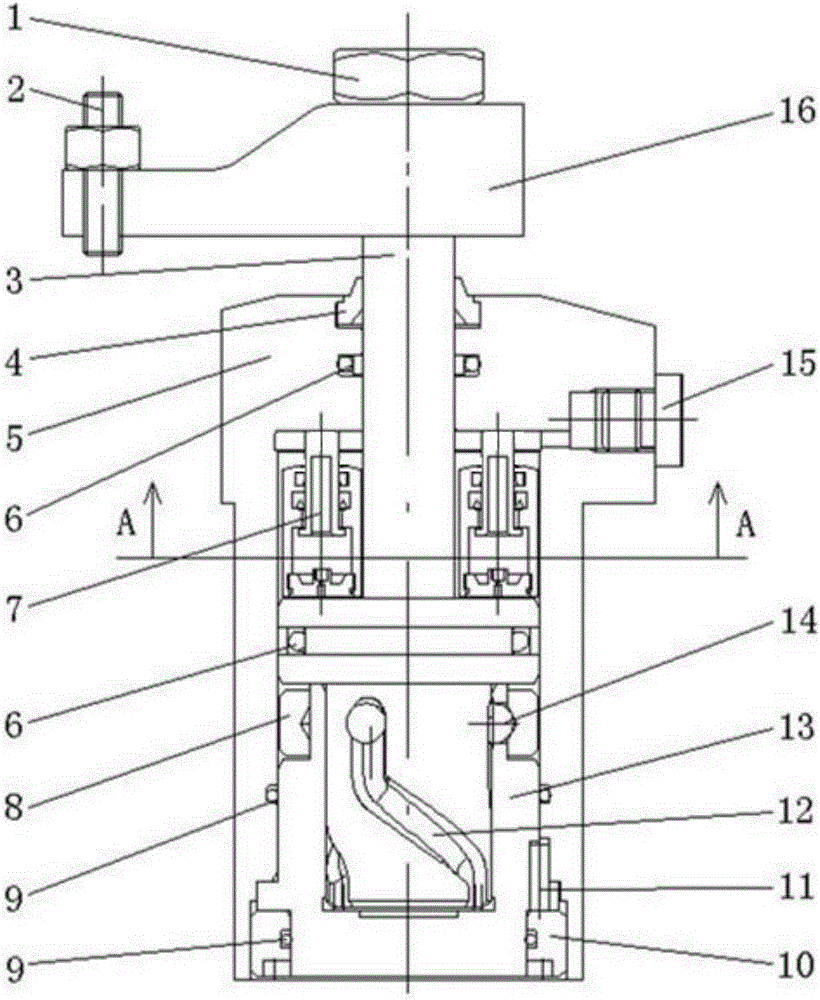

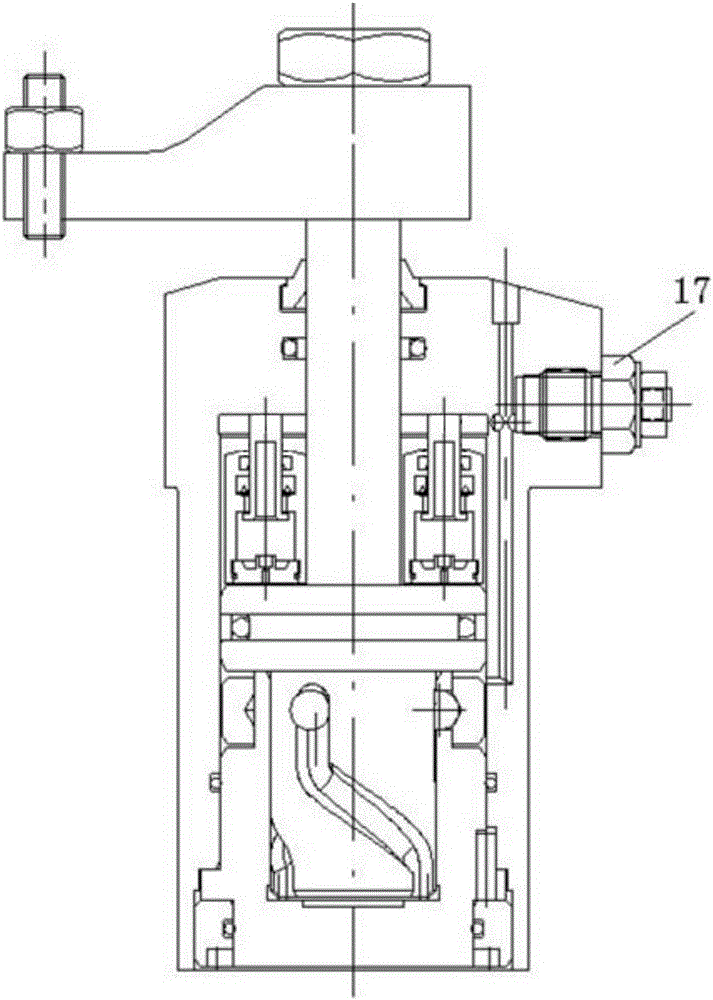

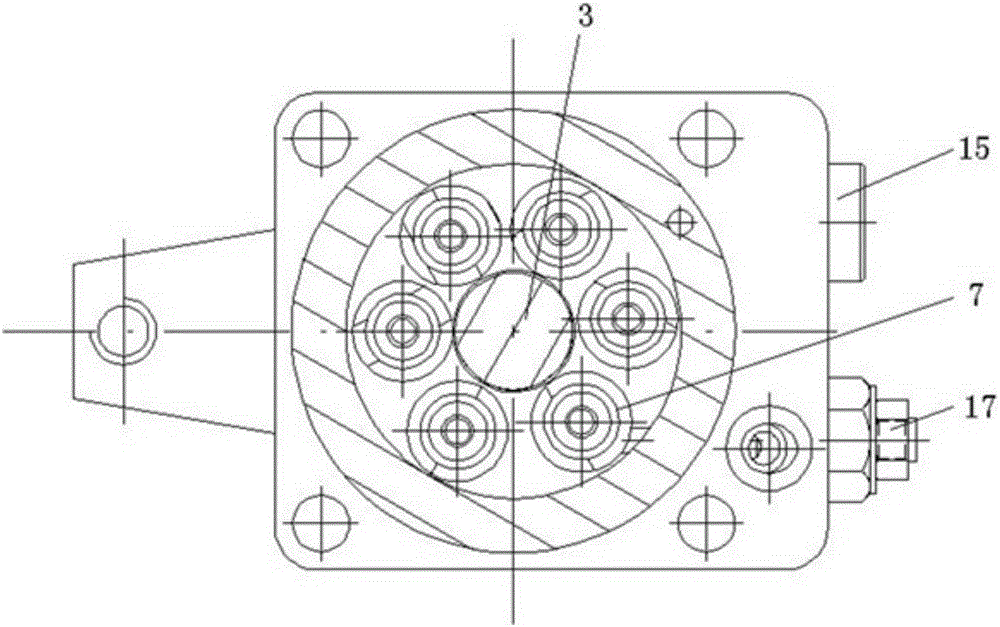

[0020] Such as Figure 1-Figure 4 As shown, the unpowered rotary clamp includes a rotary cylinder piston 3, a cylinder body 5, a nitrogen spring 7, a cylinder end cover 10, and a compression arm 16, and the inner cavity at the bottom of the cylinder body 5 is fixed and installed through a fixing ring positioning pin 11. There is a fixed ring 13 and the inner cavity of the oil cylinder body 5 and the fixed ring 13 are sealed by an O-ring 9, and an oil cylinder end cover 10 is installed between the oil cylinder body 5 and the fixed ring 13, and the oil cylinder end cover 10 and the fixed ring 13 Between them are sealed by O-rings 9; the inner chamber of the oil cylinder body 5 is equipped with a rotating oil cylinder piston 3, and the rotating oil cylinder piston 3 includes a piston rod A, a large end and a rotating part connected in sequence to form an integral structure; the rotating part is provided with There are several rotating guide grooves 12, the rotating part extends i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com