Laser rust-removing method and device, storage medium, and electronic terminal

A laser rust removal and laser technology, which is applied to laser welding equipment, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems that laser rust removal devices cannot have rust removal results, and have high requirements for rust removal results, so as to avoid incomplete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Example embodiments will now be described more fully with reference to the accompanying drawings. Example embodiments may, however, be embodied in many forms and should not be construed as limited to the examples set forth herein; rather, these embodiments are provided so that this disclosure will be thorough and complete and will fully convey the concept of example embodiments to those skilled in the art. The described features, structures, or characteristics may be combined in any suitable manner in one or more embodiments.

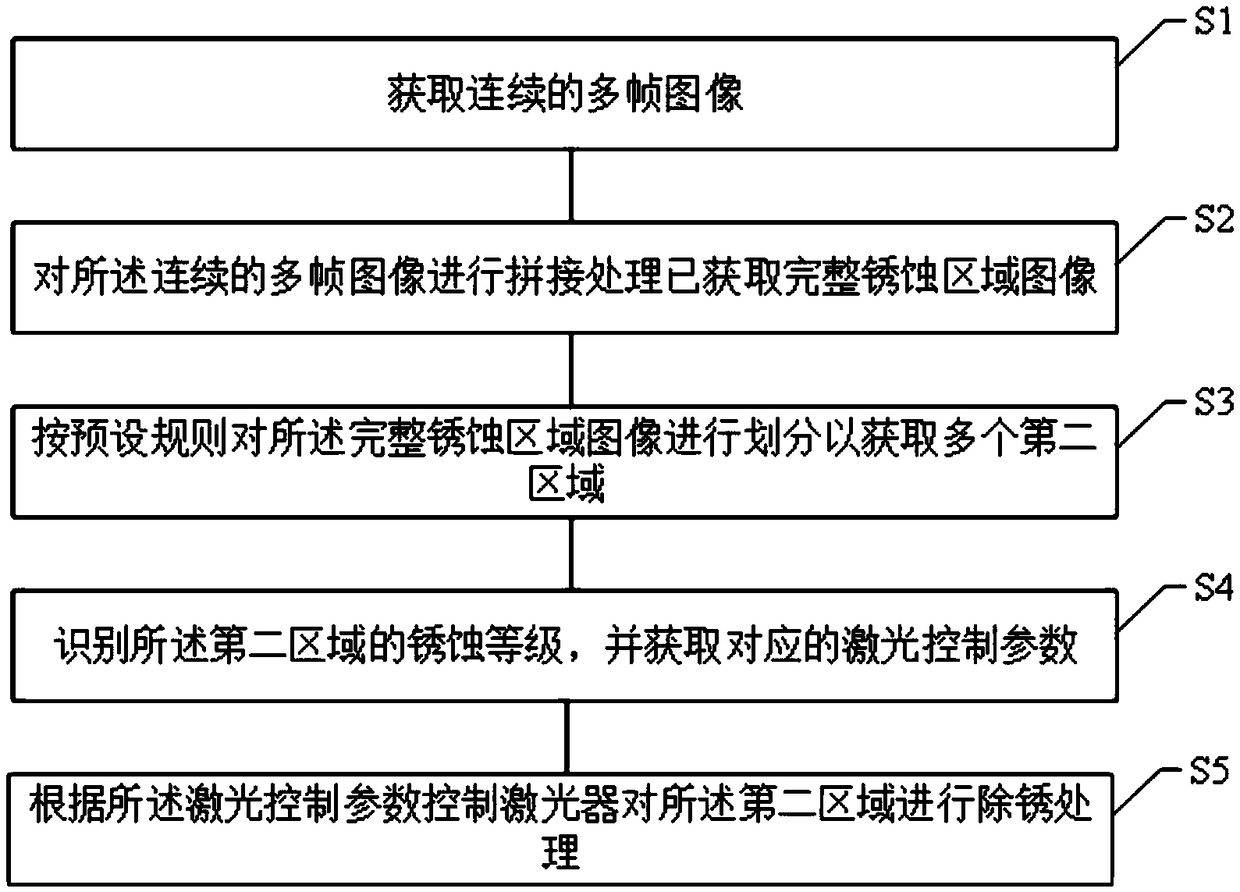

[0049] In this exemplary embodiment, a laser derusting method is firstly provided, which can be applied to derusting treatment of equipment in different scenarios, especially for rust marks on rails. refer to figure 1 Shown in, above-mentioned laser rust removal method can comprise the following steps:

[0050] Step S1, acquiring continuous multi-frame images;

[0051] Step S2, performing splicing processing on the continuous multi-frame imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com