Hydraulic tensioning sleeve tool

A technology of expansion sleeve and hydraulic pressure, which is applied in the direction of expanding the mandrel, etc., to achieve the effect of improving product quality and controlling the expansion size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

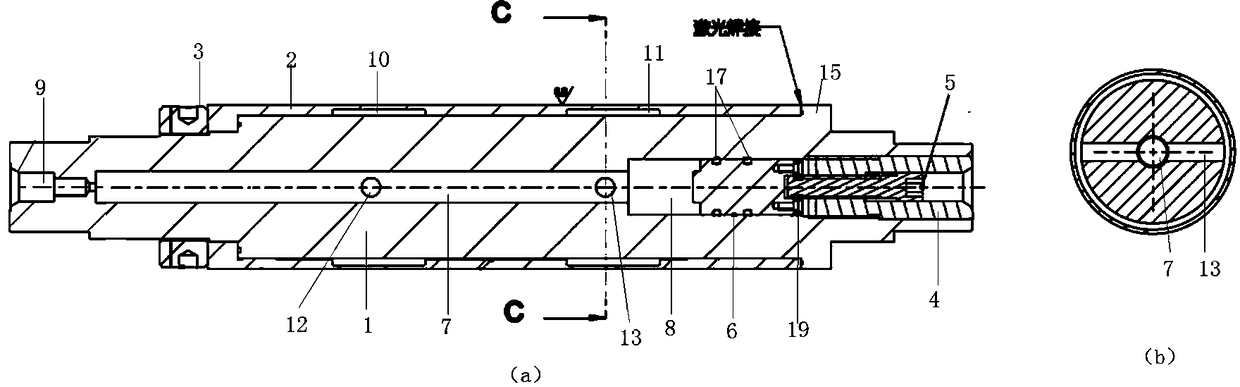

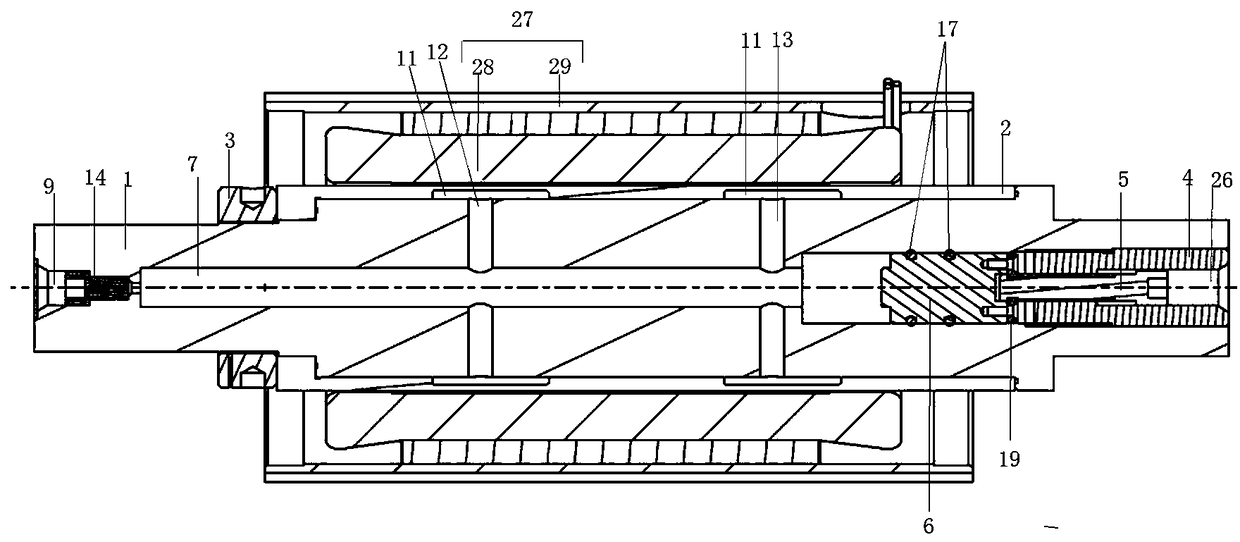

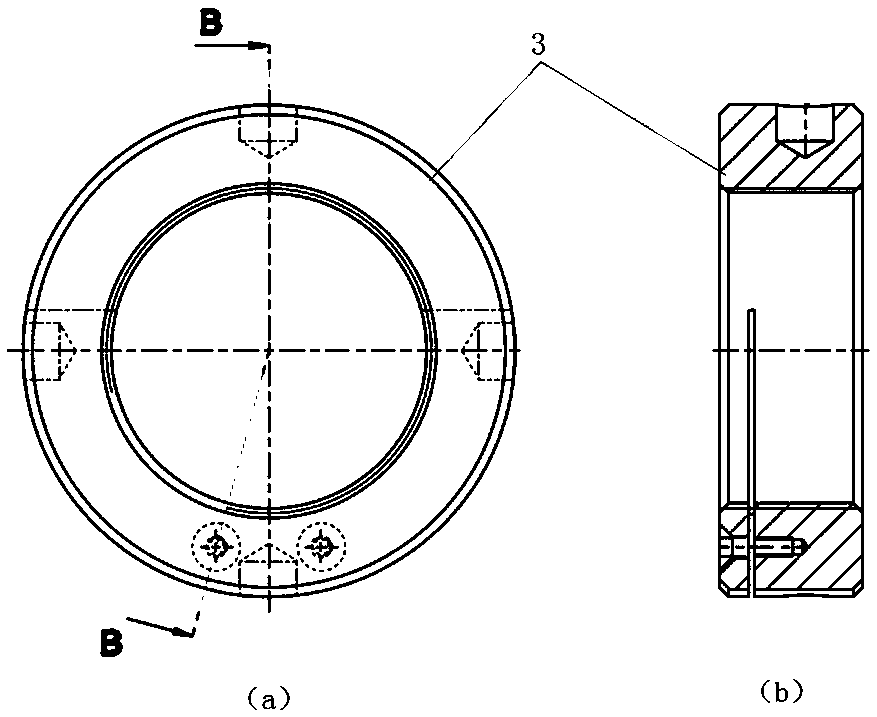

[0023] According to Figure 1 to Figure 7 The specific implementation of the present invention is further explained:

[0024] See figure 1 , figure 1 (A) is a cross-sectional view of the overall structure, figure 1 (B) in figure 1 (A) is the CC cross-sectional view of the figure. A hydraulic expansion sleeve tool of this embodiment includes a mandrel 1, a hydraulic expansion sleeve 2, a lock nut 3, a piston connecting sleeve 4, a bolt 5 and a piston 6. The core The shaft 1 is provided with an inner hole 7 and an inner hole 2 which communicate with each other along the axial direction. The left end of the mandrel 1 is provided with an oil inlet 9 and the oil inlet 9 is a threaded hole. It is connected to the inner hole 7, the diameter of the inner hole 8 is larger than the diameter of the inner hole 7 and the inner hole 8 is located at the right end of the mandrel 1 and penetrates the right end surface of the mandrel 1, the hydraulic expansion sleeve 2 is sleeved The outer side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com