Grain-refined metal powder for 3D (Three Dimensional) printing and preparation method thereof

A 3D printing and metal powder technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve problems such as uneven distribution, poor wettability, and affecting the refining effect of grain refiners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

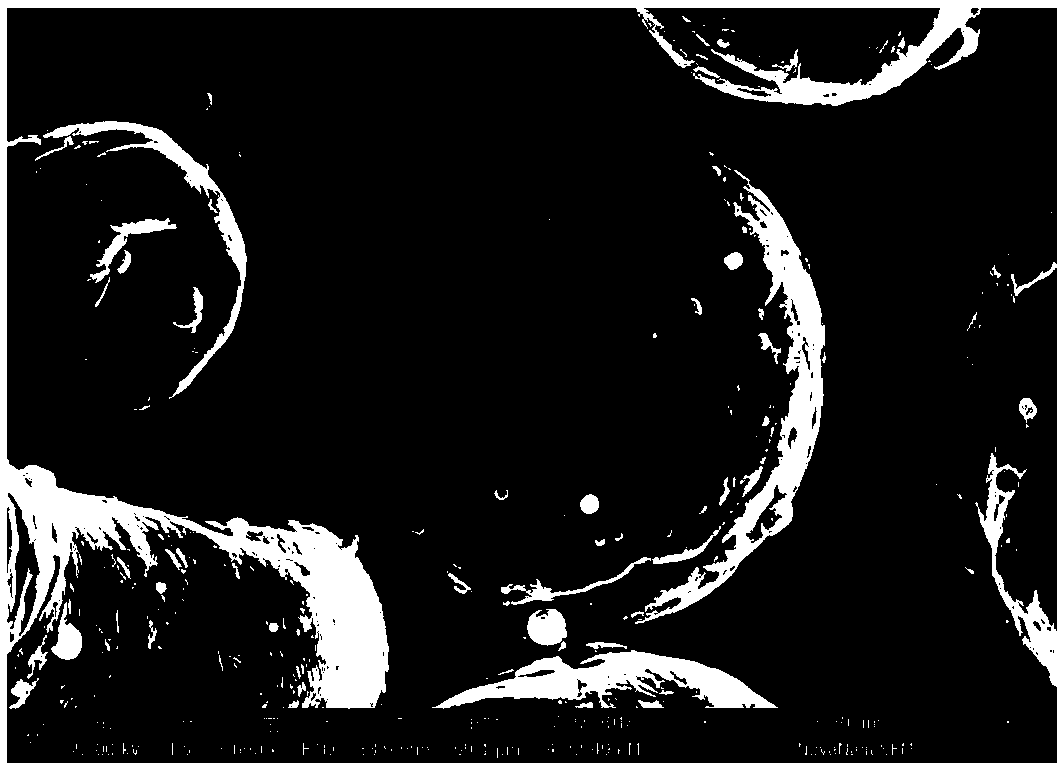

Image

Examples

preparation example Construction

[0030] The present invention will be further described in detail in conjunction with specific steps below. The present invention discloses a metal powder for 3D printing with grain refinement and a preparation method thereof; the method specifically includes the following steps:

[0031] (1) Pretreatment refiner powder

[0032] Add the refiner powder to the hydrochloric acid solution with a mass concentration of 3-10%, to ensure that the refiner powder can be completely dispersed in the hydrochloric acid solution to obtain suspension A, and the refiner is TiC, TiB 2 、TiAl 3 At least one of the refining agents can be nanoscale and micronscale, wherein the nanoscale particle size is 20-100nm, and the micron-scale particle size is 1-5μm; the suspension A is stirred on a magnetic stirrer After 2 hours of treatment, put it into a heat-collecting constant temperature stirrer and stir at 60°C for 2 hours to obtain a suspension B; let the suspension B stand until the layers of the su...

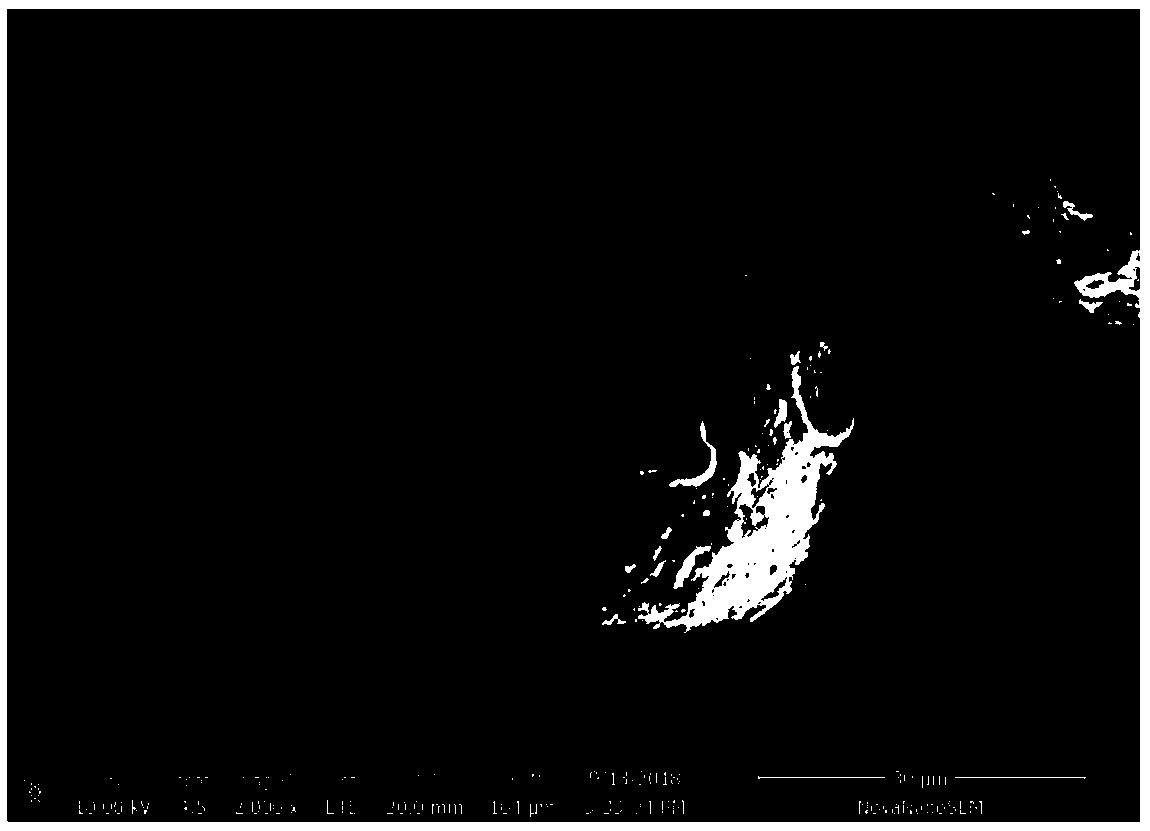

Embodiment 1

[0042] (1) Pretreatment refiner powder: 10g of nanoscale TiC powder is dissolved in a hydrochloric acid solution with a mass concentration of 5%, to ensure that the TiC powder is completely dispersed in the hydrochloric acid solution, and after stirring for 2 hours on an electromagnetic stirrer, put Put it into a heat-collecting constant temperature stirrer, stir at 60°C for 2 hours to obtain a suspension B, let the suspension B stand to separate layers, pour off the supernatant, and the remaining bottom material is a viscous intermediate product C; The viscous intermediate product C was washed 3 times with distilled water in a vacuum filter until the pH value of the suspension containing the intermediate product was 7 to obtain a suspension D; the suspension D was placed in a vacuum drying oven at 60°C Dry until the distilled water in the suspension is volatilized to obtain a lumpy pickled refiner, and grind to obtain pickled TiC powder.

[0043] (2) Preparation of metal powder...

Embodiment 2

[0048] (1) Pretreatment refiner powder: dissolve 10 g of micron-sized TiC powder in a hydrochloric acid solution with a mass concentration of 3%, to ensure that the TiC powder is completely dispersed in the hydrochloric acid solution, stir on an electromagnetic stirrer for 2 hours, and put Put it into a heat-collecting constant temperature stirrer, stir at 60°C for 2 hours to obtain a suspension B, let the suspension B stand to separate layers, pour off the supernatant, and the remaining bottom material is a viscous intermediate product C; The viscous intermediate product C was washed 3 times with distilled water in a vacuum filter until the pH of the suspension containing the intermediate product was 6.5 to obtain a suspension D; the suspension D was placed in a vacuum drying oven at 60°C Dry until the distilled water in the suspension is volatilized to obtain a lumpy pickled refiner, and grind to obtain pickled TiC powder.

[0049] (2) Preparation of metal powder containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com