A kind of air drying filter element and using method thereof

A technology of air drying and filter elements, which is applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., and can solve the problems of difficult cleaning and waste of air filter elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

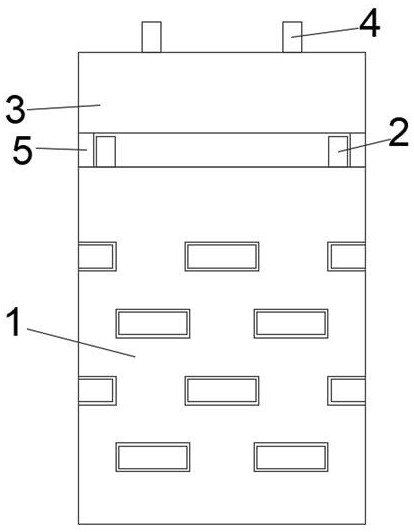

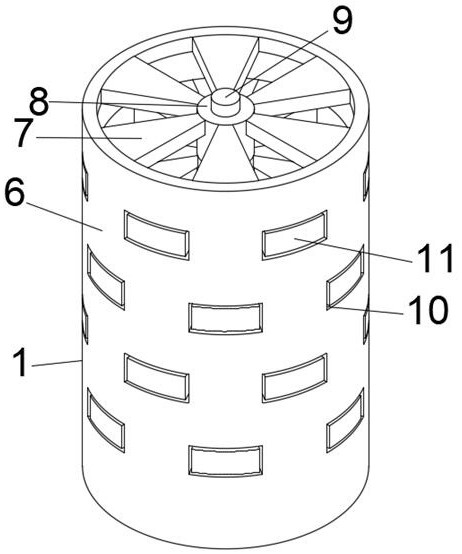

[0031] Embodiment 1: refer to Figure 1-2 ;

[0032] An air-drying filter element, including a vent pipe 3, and a filter element device 1, the upper end of the filter element device 1 is provided with an external thread 2, the lower end of the vent pipe 3 is provided with an internal thread 5, and the internal thread 5 is threadedly connected with the external thread 2, The upper end of the air pipe 3 is provided with a connecting thread 4 for connecting the air filter equipment. The filter element device 1 includes a filter element tube 6, and the opening wall of the upper end of the filter element tube 6 is fixedly connected with a plurality of sets of connecting plates 7, and the inner ends of the connecting plates 7 are connected to the The outer surface of the upper end of the column 8 is fixedly connected, the upper end of the connecting column 8 is movably installed with a tenon joint device 9, and the outer surface of the filter tube 6 is intersected and arranged with ...

Embodiment 2

[0036] Embodiment 2: refer to Figure 3-6 , the basis of the embodiment 1 is different in that;

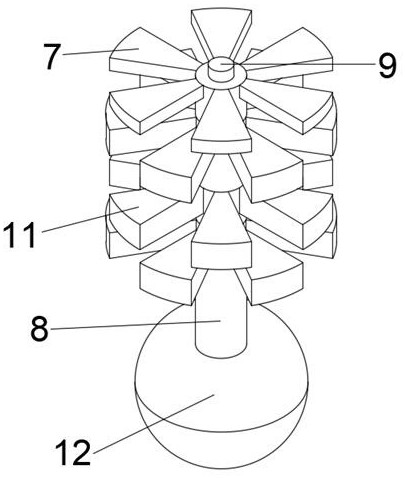

[0037] The tenon joint device 9 includes a twist block 15, the lower surface of the twist block 15 is fixedly connected with the upper end surface of the twist bar 16, and the twist bar 16 is placed inside the connecting column 8 as a whole, and the outer surface of the upper end of the twist bar 16 is connected to the support The inner ring of the bearing 17 is fixedly connected, the outer ring of the support bearing 17 is fixedly connected with the inner wall of the upper opening 13, and the outer surface of the middle part of the twist rod 16 is provided with multiple sets of tenon joint sleeve rods 19 for tenon joint filter plate device 11, tenon joint sleeve The rod 19 is fixedly connected with the outer surface of the middle part of the twist rod 16 through the connecting rod 18 .

[0038] The filter plate device 11 includes a sealing plate 20, the sealing plate 20 is match...

Embodiment 3

[0043] A method for using an air-drying filter element. The method for using an air-drying filter element is applied to an air-drying filter element. The method uses the following steps:

[0044] S1. First, clean the filter plate device 11 quickly, and then align the wall notches 10 on the filter core tube 6 and insert them one by one, and align the inner end of the filter baffle plate 22 in the filter plate device 11 with the connection column 8. The bayonet 14 is sealed and embedded, so that the tenon joint sleeve 25 and the tenon joint sleeve rod 19 are located on the same arc track, and the sealing plate 20 and the wall notch 10 are sealed and placed.

[0045] S2. Next, turn the tenon joint device 9 on the connecting column 8, turn the twist block 15 clockwise, and drive the tenon joint sleeve rod 19 on the twist bar 16 to go around the same arc track as the tenon joint sleeve pipe 25 Click clockwise to realize effective fixation of multiple sets of filter plate devices 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com