Single-power-source hydraulic auxiliary synchronous lifting table

A technology of synchronous lifting and single power source, which is applied to tables, legs of general furniture, and tables with variable table heights, etc. It can solve the problems of difficult synchronization of lifting legs, high manufacturing cost, and complex structure, and achieves compact structure and easy use. The effect of long life and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

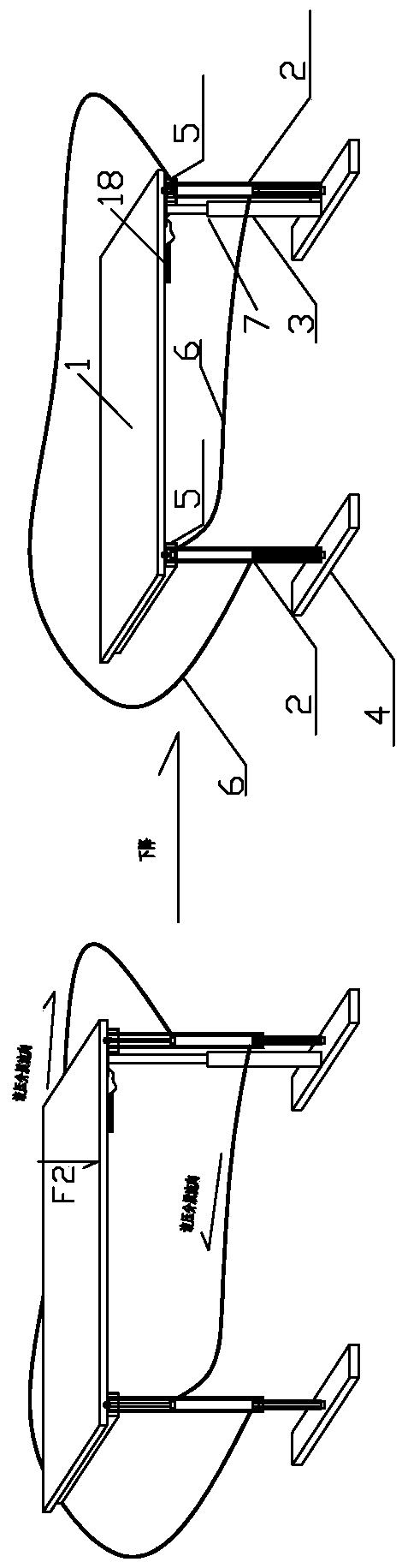

[0058] Such as figure 1 , 2 , 9-12 shown.

[0059] A single power source hydraulic auxiliary synchronous lift table, which includes a desktop 1, two hydraulically driven lifting legs 2, and a pneumatic (hydraulic) dynamic telescopic rod or pneumatic (mechanical) tension and compression spring mechanism 7 as a driving lifting leg 2 follow-up power source legs 3 and base 4, such as figure 1 , 2 As shown, the lifting leg 2 is composed of a hydraulic cylinder and a piston rod. The rod chamber of the first hydraulic cylinder communicates with the rodless chamber of the second hydraulic cylinder through a flexible hydraulic tube 6, and the rod chamber of the second hydraulic cylinder The rod chamber communicates with the rodless chamber of the first hydraulic cylinder through the flexible hydraulic tube 6; when the power source leg 3 rises ( figure 2 ) or drop ( figure 1 ) drives the desktop 1 to rise or fall, and the rise or fall of the desktop 1 drives the piston rods of eac...

Embodiment 2

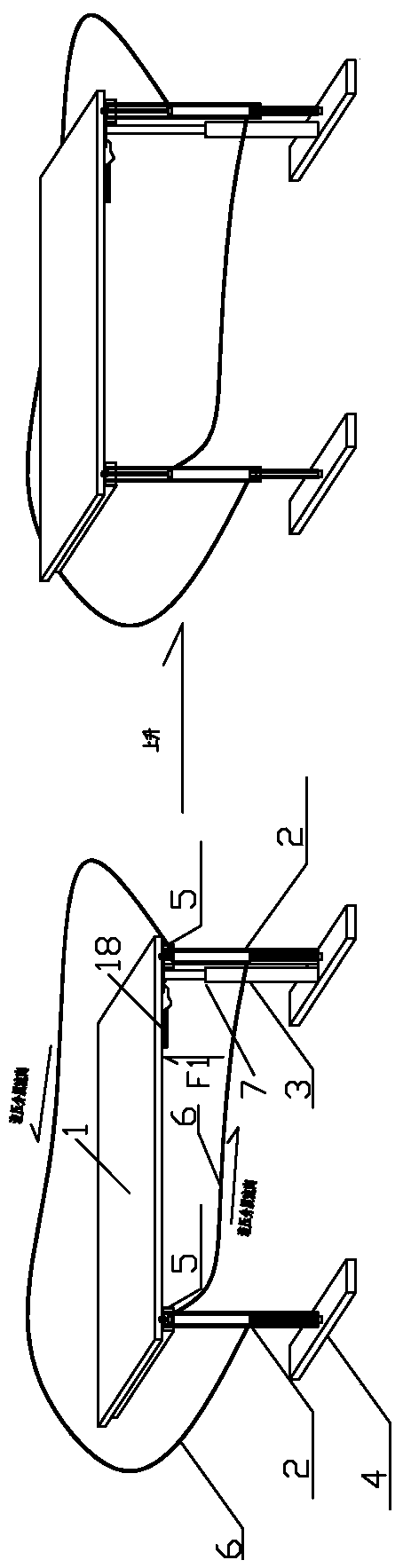

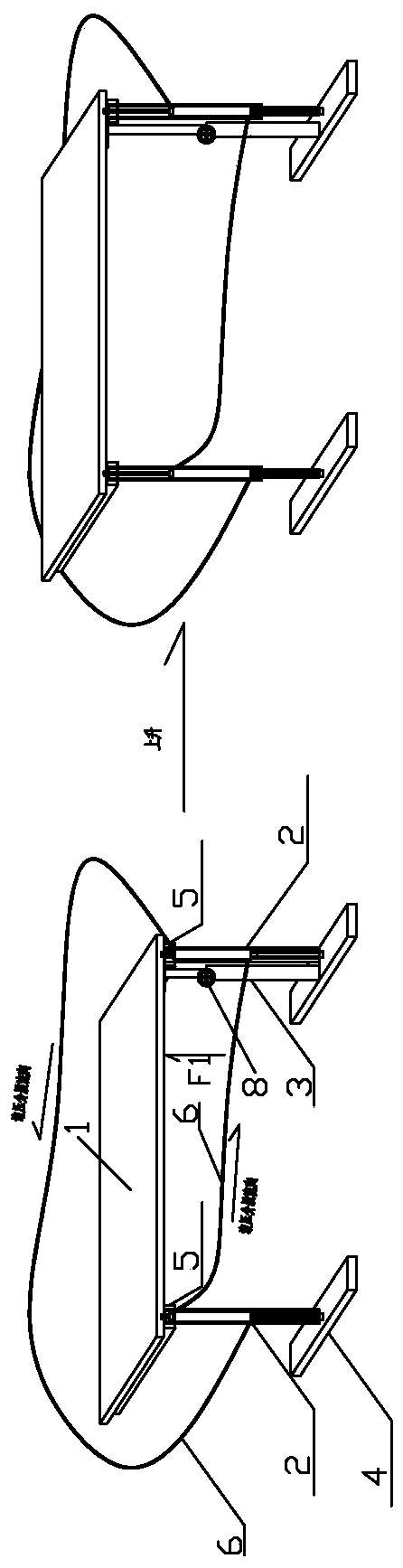

[0065] Such as image 3 , 4 shown.

[0066] The difference between this embodiment and Embodiment 1 is that as the power source leg 3 that drives the lifting leg 2 to go up and down, a separate hand crank lifting mechanism, a foot pedal lifting mechanism or a human mechanical power transmission mechanism 8, a hand rocker lifting mechanism, Pedal elevating mechanism or manpower mechanical force transmission mechanism 8 can adopt the same structure as adopting on the existing lifting table. The rest are all the same as in Example 1.

Embodiment 3

[0068] Such as Figure 5-6 shown.

[0069] The difference between this embodiment and Embodiment 1 is that as the power source leg 3 that drives the lifting leg 2 to lift, it adopts a separate motor lifting mechanism or a motor force transmission mechanism 9, and the motor lifting mechanism or motor force transmission mechanism 9 is the same as the existing lifting table. The structure adopted above is identical, all adopts motor 10 as power source. The rest are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com