All-secondary air cooled industrial steam condenser

An air-cooled, steam-condensing technology, applied in the direction of evaporator/condenser, steam/steam condenser, refrigerator, etc., to achieve the effect of less total space and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

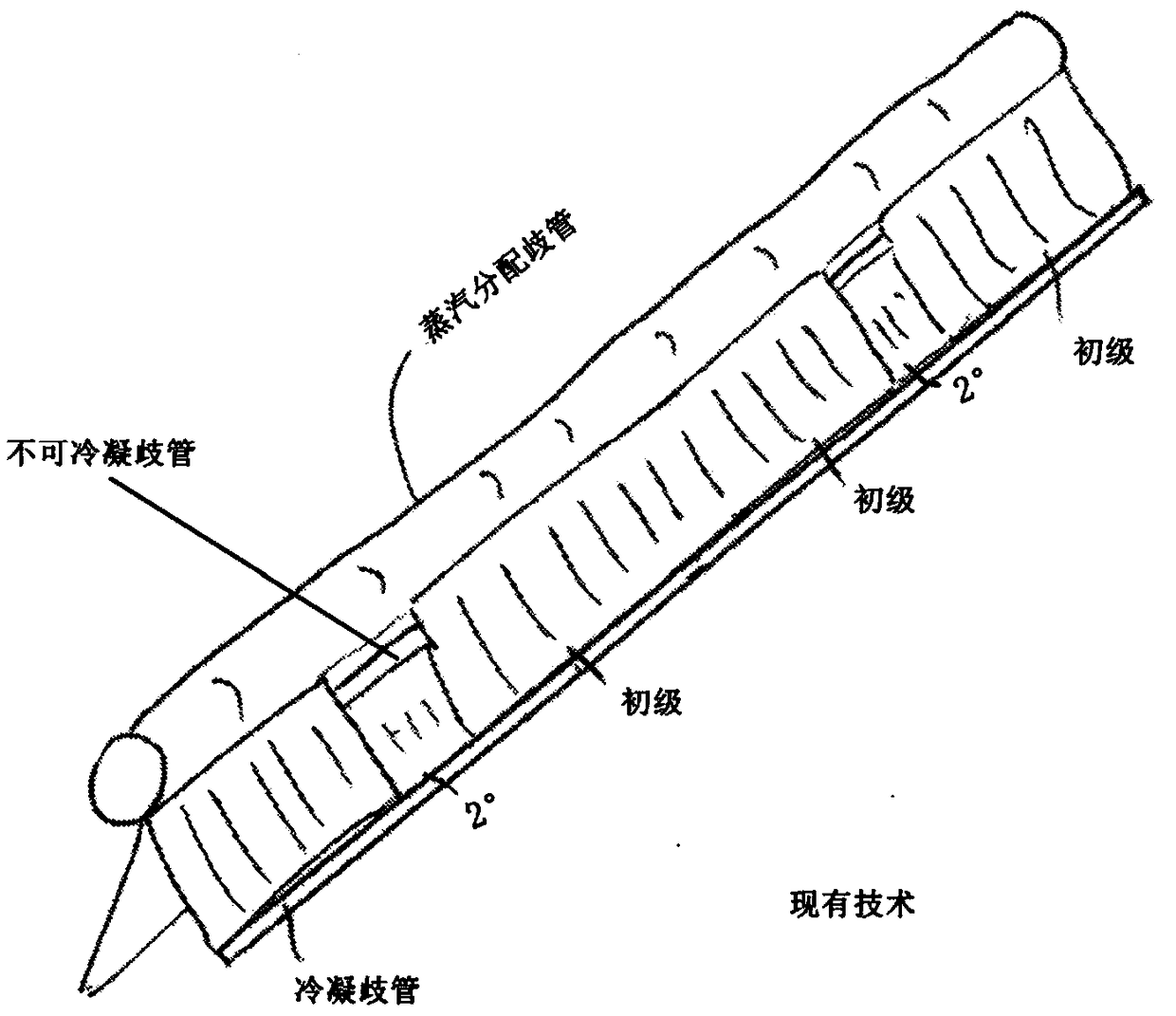

[0043] A-frame ACC with full secondary tube bundles

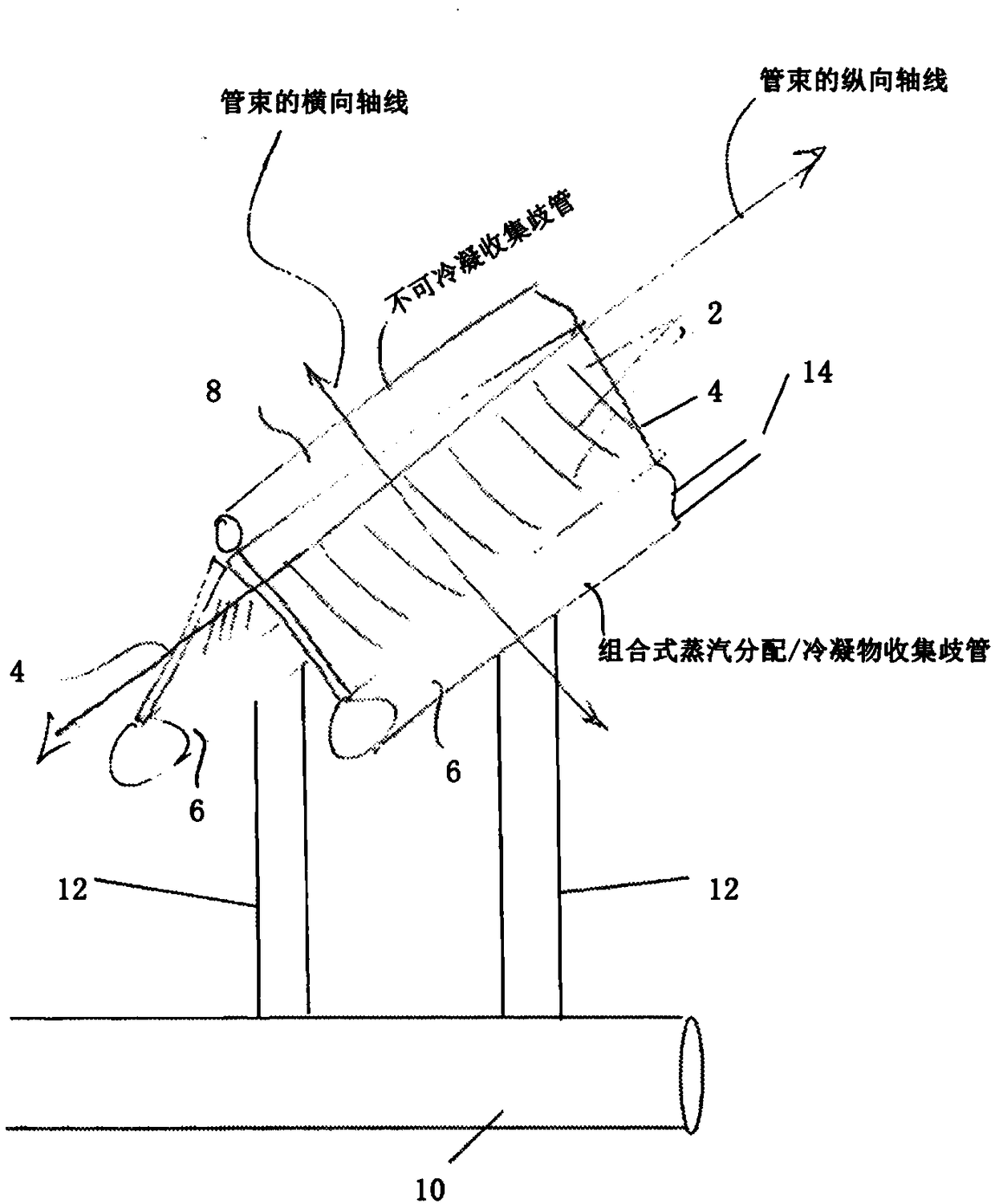

[0044] refer to figure 2 , the tubes 2 are arranged in the secondary tube bundle 4 . The longitudinal axis of the tubes 2 is aligned parallel to the transverse axis of the tube bundle, each tube generally at an angle of 25°-35°, preferably 30°, from the vertical. A combined steam distribution / condensate collection manifold 6 is attached at the bottom of each of the two secondary tube bundles 4 joined at their top to form an A-frame structure. Steam is distributed to tube 2 through the combined steam distribution / condensate collection manifold 6 and forms in tube 2 as the steam condenses and travels down the tube 2 into the combined steam distribution / condensate collection manifold 6 condensate. A single non-condensable collection manifold 8 is attached to the top of the two tube bundles 6 to collect the non-condensable gases traveling to the top of the tubes 2 . Steam is supplied from the steam line 10 to the combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com