High-efficiency and low-noise rotary valve and oxygen generator thereof

A low-noise, rotary valve technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of difficult sealing, difficult processing, and complex rotary valve structure, so as to reduce processing costs, reduce sealing difficulty and processing. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

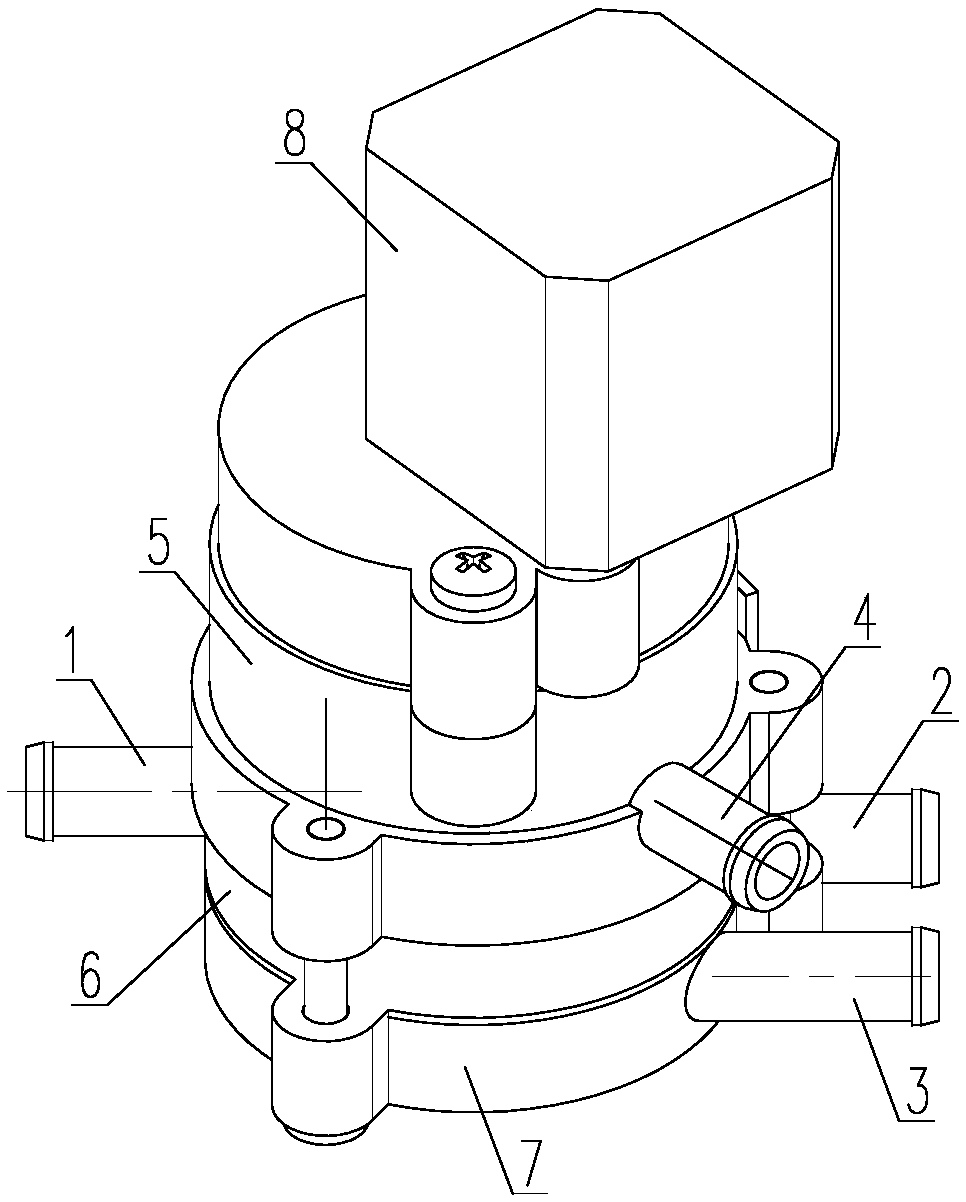

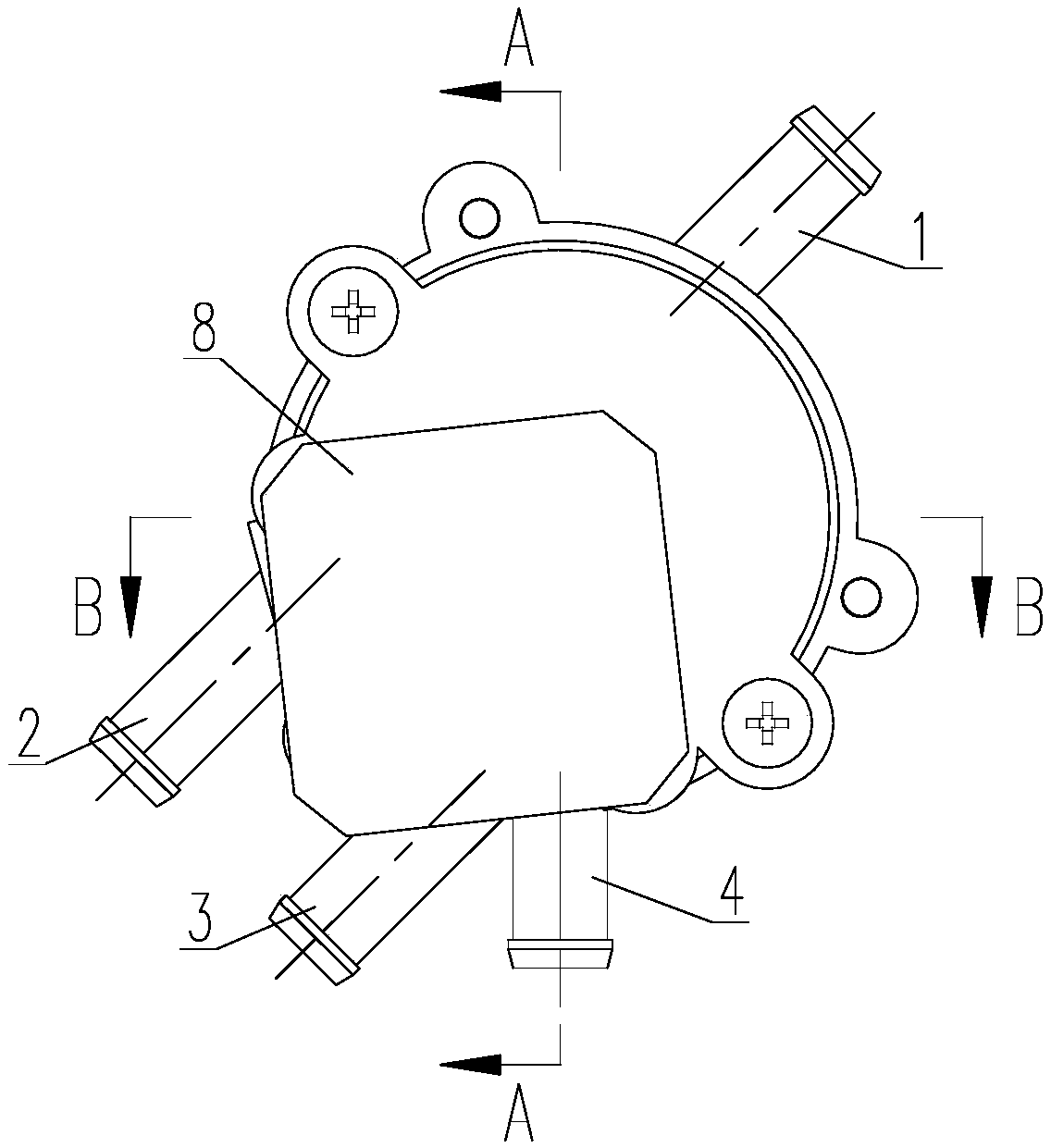

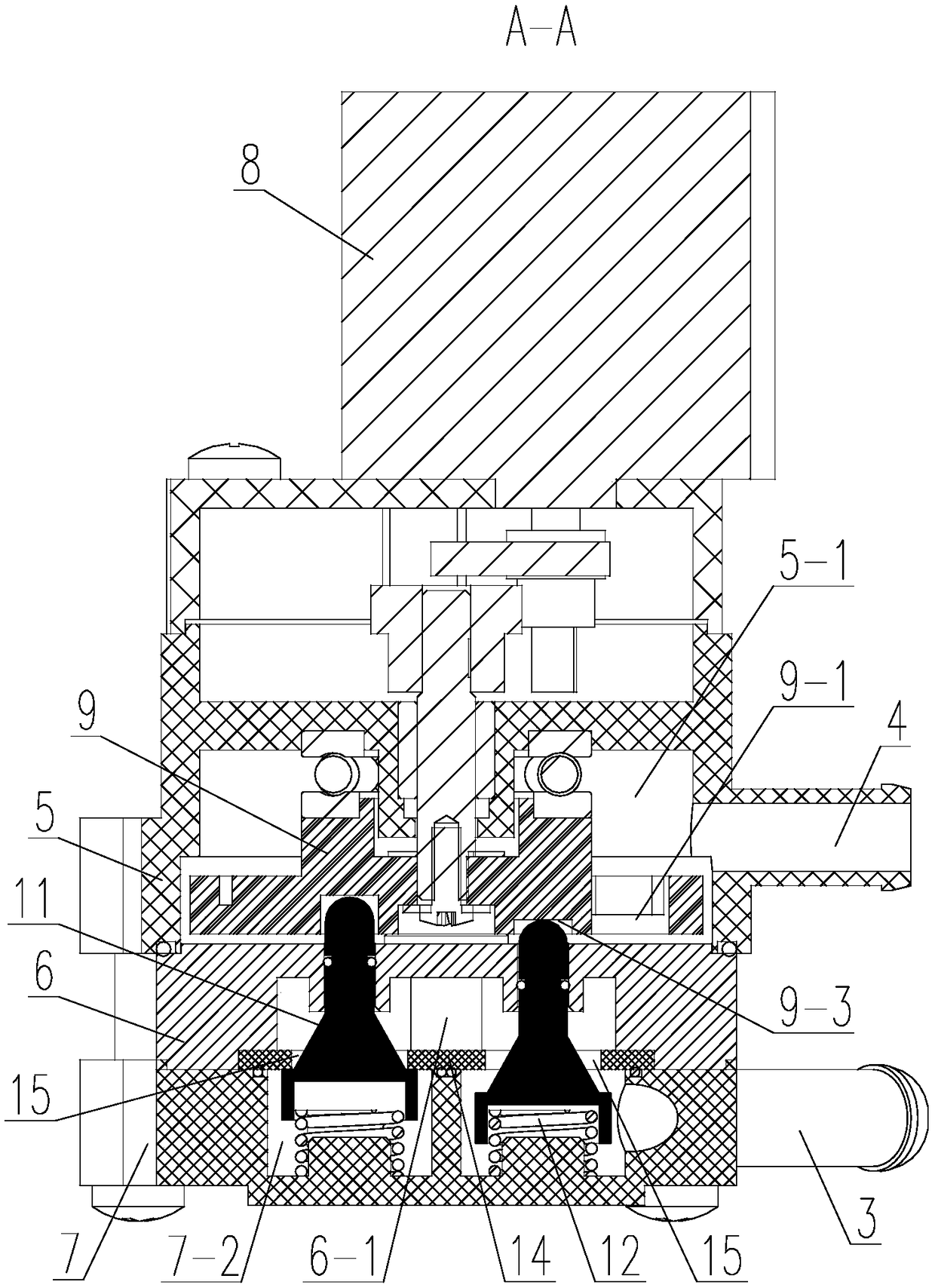

[0037] Such as Figure 1-4 As shown, a high-efficiency and low-noise rotary valve includes a valve body assembly, a cam structure, a movable valve plate 9 rotatably arranged in the valve body assembly, and a power device 8 for driving the movable valve plate 9 to rotate. The valve body assembly has an air inlet 4, a first air outlet 1, a second air outlet 2, and a third air outlet 3;

[0038] A gas distribution groove 9-1 penetrates through the movable valve plate 9, and a reinforcing rib 9-2 can be arranged in the gas distribution groove 9-1 to improve the structural strength of the movable valve plate 9 near the gas distribution groove 9-1. Through the rotation of the movable valve plate 9, the air distribution groove 9-1 can connect the air inlet 4 with the second air outlet 2 or / and the third air outlet 3. The second air outlet 2 and the third row Each of the air ports 3 communicates with the first exhaust port 1 through a passage 15, and the passage 15 is blocked with a pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com