High voltage generator and control method

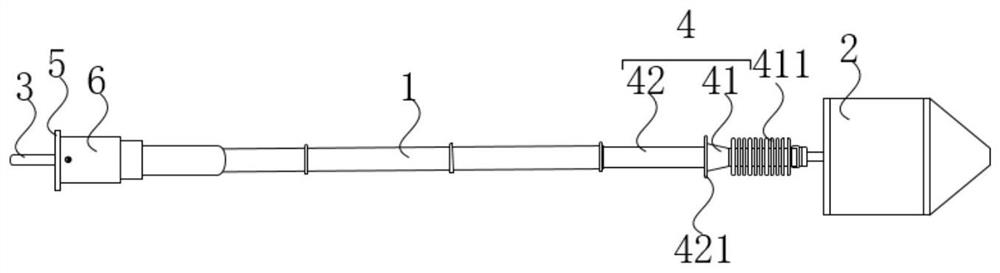

A high-voltage generator and distance control technology, which is applied in the direction of instruments, electrical measuring instrument parts, measuring devices, etc., can solve the problems of reducing safety, unable to guarantee the safe distance between the power supply end and the holding end, and improve safety , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0056] This embodiment provides a high-voltage generator, and compared with Embodiment 1, the structure provided by this embodiment is basically the same as Embodiment 1, and this embodiment will not repeat the same structure as Embodiment 1.

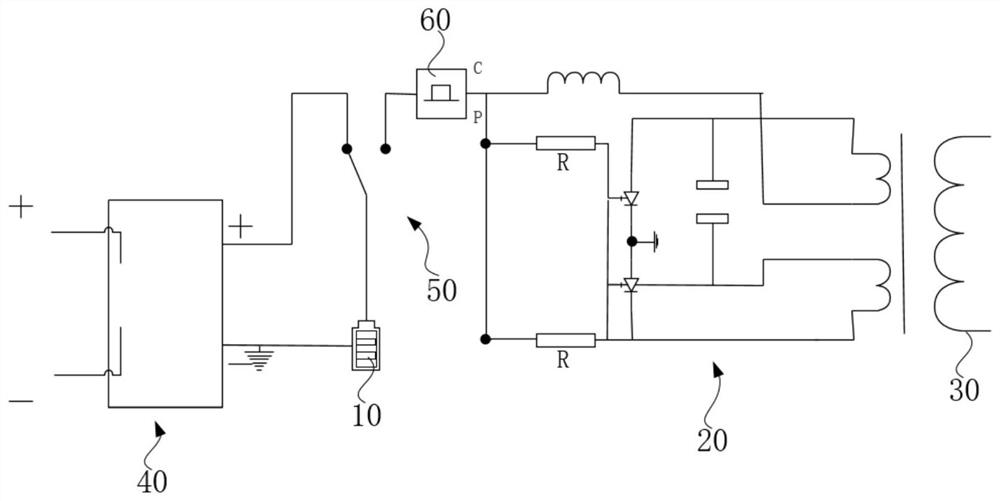

[0057] In this embodiment, the power supply 10 is a rechargeable battery. Preferably, as figure 2 As shown, the high voltage generator also includes a charging module 40 . The charging module 40 includes a charging circuit, the charging circuit is connected to the power supply 10, and the external power supply can charge the power supply 10 through the charging circuit, so that the power supply 10 can be reused and the service life is prolonged.

[0058] Further, the high-voltage generator also includes a switching module 50. When the external power supply charges the power supply 10 through the charging circuit, the switching module 50 can disconnect the power supply 10 and the boost circuit; when the external power supply and the po...

Embodiment 3

[0061] This embodiment also provides a control method, which is applied to the high voltage generator as described in Embodiment 1 or Embodiment 2. The above control methods include:

[0062] Set the preset safety distance according to the detection voltage;

[0063] The distance sensor obtains the actual distance between the handle 3 and the power supply end 30;

[0064] Compare the preset safety distance with the actual distance;

[0065] If the actual distance is not less than the preset safety distance, the distance control switch 60 is turned on, otherwise, the distance control switch 60 is turned off.

[0066] In a control method provided in this embodiment, when the high-voltage generator is working, the distance control switch 60 automatically compares the actual distance between the handle and the power supply terminal 30 detected by the distance sensor with the safety distance required for voltage detection. Controlling the on-off of the boost circuit improves saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com