Bidirectional thrust angular contact ball bearing nylon retainer ball loading device

A technology of angular contact ball bearings and two-way thrust, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of affecting the service life of bearings, increasing the noise of bearing products, affecting the qualified rate of products, etc., to prevent extrusion damage , Improve work efficiency and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

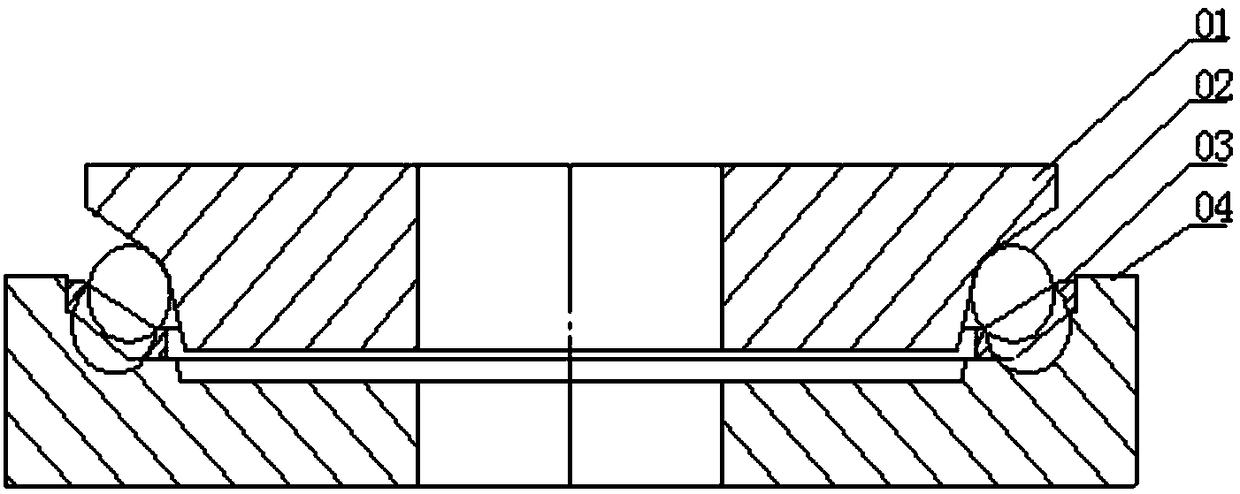

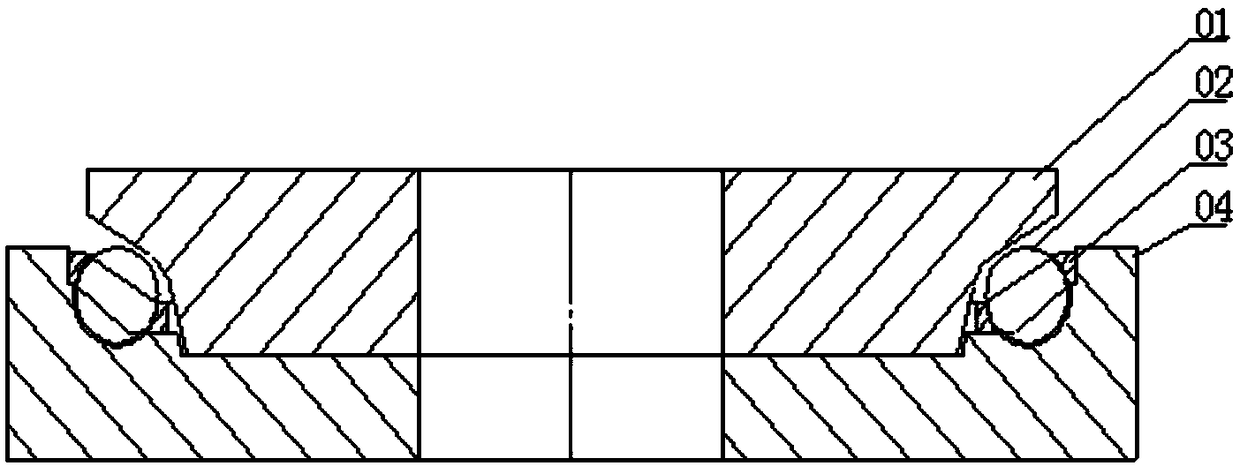

[0011] Ball tire 01 and ball tire 04 are made of nylon material. The lower end of ball tire 01 is a curved body corresponding to steel ball 02; the upper end of ball tire 04 is a table surface corresponding to nylon cage 03 and steel ball 02. Concave surface; ball tire 01 and ball tire 04 are coaxial, put the nylon cage 03 flat on the ball tire 04, fill the steel ball 02 into the pocket hole of the nylon cage 03, and then put the ball tire 01 on the The steel ball 02 is placed under the press, and the one-time pressing installation is completed.

[0012] Before and after the steel ball 02 is pressed in, the pressure ball tire 01 will not contact the nylon cage 03, so as to avoid the deformation of the nylon cage 03; Large crushing damage to the steel ball.

[0013] When working, two people are required to cooperate and work together. One pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com