A control system of presser foot lifter electromagnet driven by multi-mode output

A technology of output drive and control system, which is applied in control devices for sewing machines, cloth press mechanisms, textiles and papermaking, etc. It can solve problems such as the mechanical structure of the presser foot that is easily damaged, the service life of the presser foot is short, and the quality of the product is affected. Achieve the effects of avoiding fabric damage, prolonging service life and avoiding equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the implementation method of the present invention is not limited thereto.

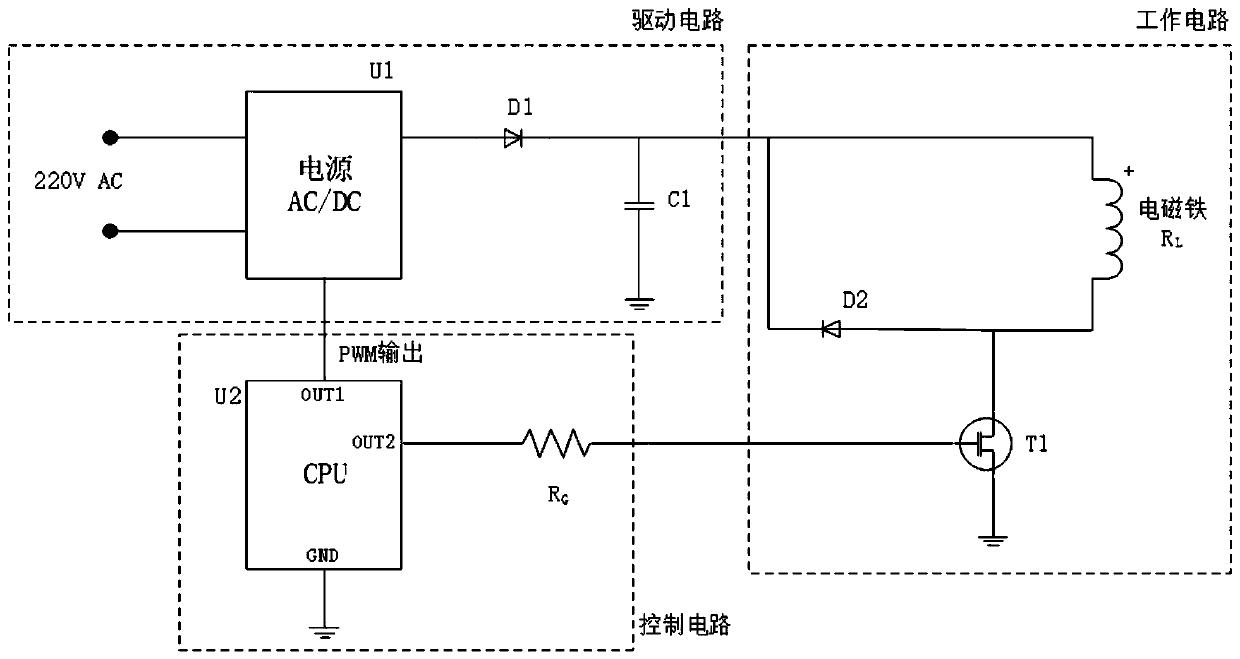

[0032] Such as figure 1 As shown, the present embodiment provides a multi-mode output-driven presser foot lifter electromagnet control system, including: a driving circuit, a control circuit and a working circuit.

[0033] The driving circuit includes a power supply unit U1, a diode D1 and a capacitor C1; the power supply unit U1 includes two AC input terminals, a control terminal and an output terminal, and the two AC input terminals of the power supply unit U1 are electrically connected to a 220V AC power supply, and the output of the power supply unit U1 terminal is electrically connected to the anode of the diode D1, the cathode of the diode D1 is electrically connected to the first end of the capacitor C1, and the second end of the capacitor C1 is grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com