An electro-hydraulic proportional multi-hydraulic winch control system and its control strategy

A technology of hydraulic winch and electro-hydraulic ratio, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation device, hoisting device, etc., and can solve problems such as useless consumption of energy, difficulty in precise coordination of multiple winches, and large space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

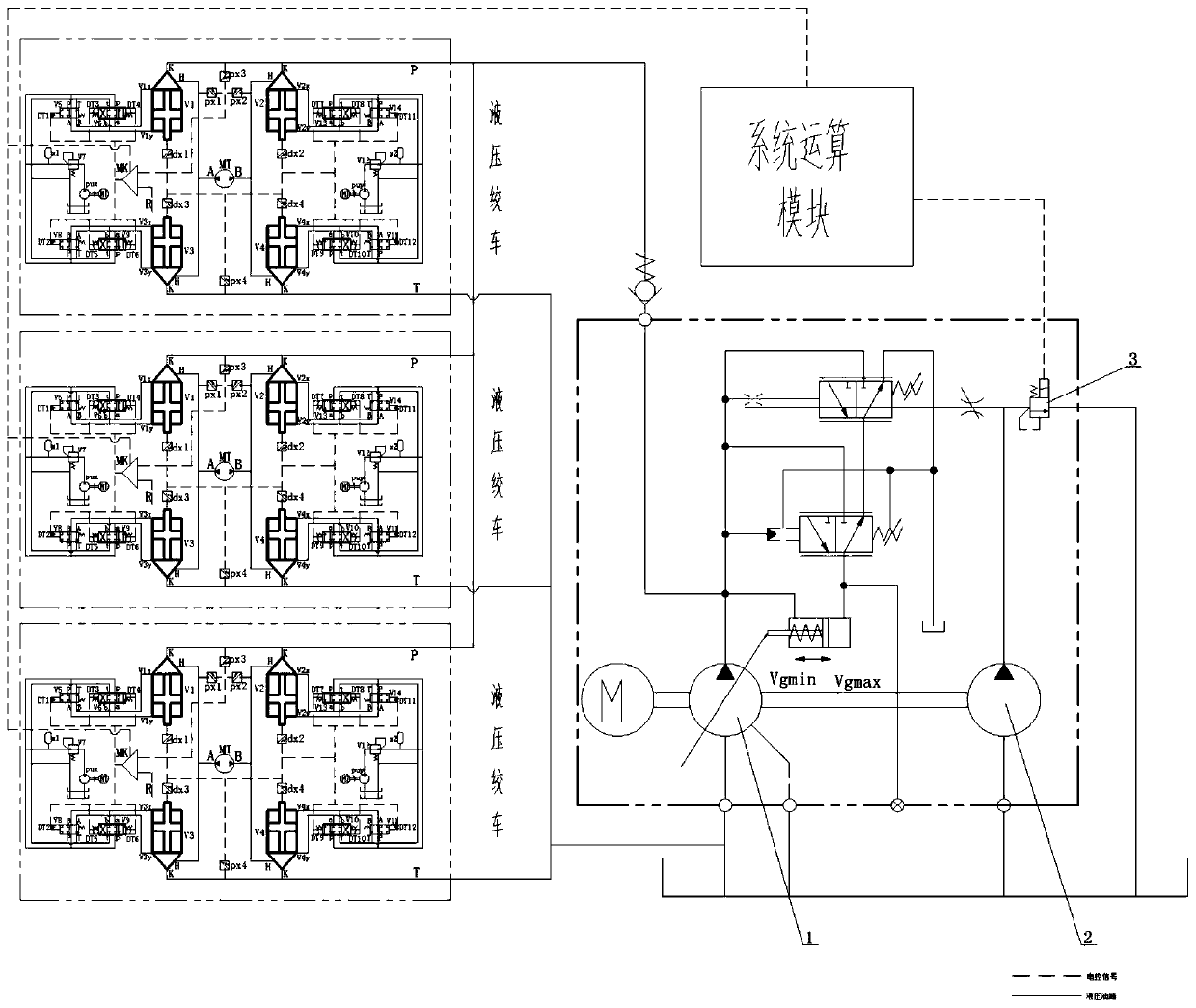

[0152] see figure 1 , an electro-hydraulic proportional multi-hydraulic winch control system, including three hydraulic winches, a load sensing pump 1, a control pump 2, an electric proportional overflow valve 3 and a system operation module.

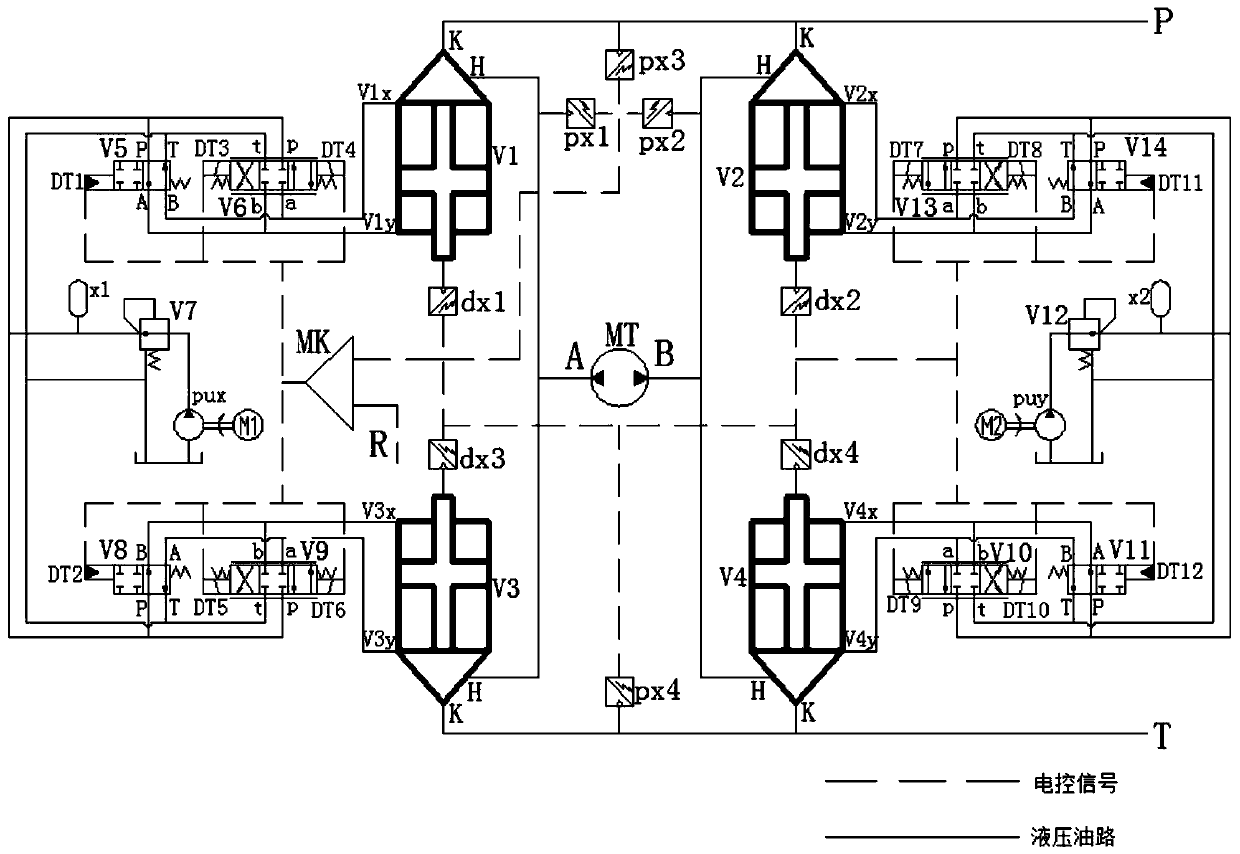

[0153] see Figure 1 to Figure 2 , the three hydraulic winches are equipped with electro-hydraulic proportional integrated controllers, and the electro-hydraulic proportional integrated controllers include two-way cartridge valve V1, two-way cartridge valve V2, two-way cartridge valve V3, two-way One-way cartridge valve V4, operational amplification module MK, two-way working hydraulic motor MT, two-position four-way electromagnetic directional valve V5, two-position four-way electromagnetic directional valve V8, two-position four-way electromagnetic directional valve V11, two-position four-way electromagnetic directional valve Electromagnetic directional valve V14, three-position four-way electromagnetic proportional directional valve...

Embodiment 2

[0164] see figure 1 , a control strategy of the electro-hydraulic proportional multi-hydraulic winch control system, corresponding to the three working conditions of the hydraulic winch: rising, neutral stop, and falling. The pressure output of the load-sensitive pump 1 is based on the handle working position and The pressure signals of the pressure sensors px1, px2, px3, and px4 are calculated and then output corresponding control signals to power the proportional overflow valve 3, so that the load sensitive pump 1 outputs the pressure required by the hydraulic winch system. Specifically, it includes the following contents of S1, S2, and S3:

[0165] S1, when the system has an ascending working condition, the highest pressure of the pressure sensor px2 of the hydraulic winch corresponding to all ascending working conditions is output to the electro-hydraulic proportional relief valve 3 as a system control pressure signal.

[0166] S2, when all the hydraulic winches are in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com